Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glass Edger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

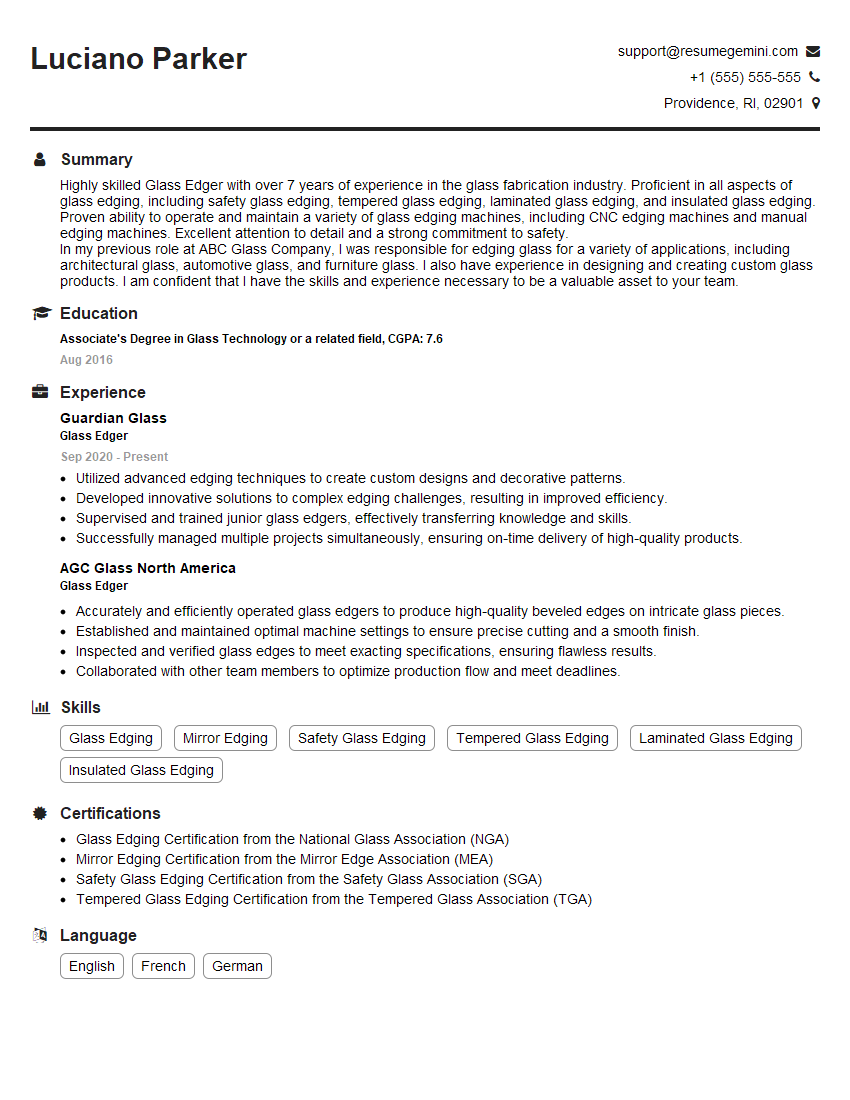

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Edger

1. What are the different types of glass edging machines used in the industry?

There are several types of glass edging machines used in the industry, here are some common ones:

- Straight Line Edging Machine: This machine is used to create straight edges on glass, and it is commonly found in small to medium-sized glass fabrication shops.

- Beveling Machine: This machine is used to create beveled edges on glass, which is often used for decorative purposes or to create unique designs.

- Profiling Machine: This machine is used to create complex shapes and profiles on glass, and it is commonly used in the production of architectural glass.

- Polishing Machine: This machine is used to polish the edges of glass to achieve a smooth and glossy finish.

- Waterjet Cutting Machine: This machine uses a high-pressure waterjet to cut glass into precise shapes, and it is commonly used in the production of artistic glass and architectural glass.

2. Can you explain the process of tempering glass, and what are the advantages of tempered glass?

Tempering Process

- Cutting the glass to the desired size and shape.

- Heating the glass to a high temperature (around 620°C).

- Rapidly cooling the glass by blowing cold air onto it.

Advantages of Tempered Glass

- Increased Strength: Tempered glass is about four to five times stronger than regular glass, making it more resistant to breakage.

- Safety: When tempered glass breaks, it shatters into small, relatively harmless pieces instead of sharp shards, reducing the risk of injury.

- Heat Resistance: Tempered glass can withstand higher temperatures than regular glass without breaking.

- Increased Durability: Tempered glass is more resistant to scratches and abrasions than regular glass.

3. What are the different types of glass coatings, and what are their applications?

- Anti-Reflective Coating: Reduces reflections on glass surfaces, making it useful for optical applications and display screens.

- Low-Emissivity Coating: Reflects heat back into the room, improving energy efficiency in buildings.

- UV-Blocking Coating: Blocks harmful ultraviolet rays, protecting people and furniture from sun damage.

- Solar Control Coating: Reduces heat gain from sunlight, keeping buildings cooler.

- Self-Cleaning Coating: Repels water and dirt, making it easier to maintain glass surfaces.

4. How do you ensure the quality of your glass edges?

- Using high-quality edging machines that are regularly maintained and calibrated.

- Implementing strict quality control procedures and inspections throughout the edging process.

- Employing skilled and experienced glass edgers who pay attention to detail.

- Using specialized tools and techniques to achieve precise and consistent edge quality.

- Conducting regular training and certification programs for our glass edgers to ensure they are up-to-date with the latest industry standards and best practices.

5. What are some of the challenges you have encountered as a Glass Edger, and how did you overcome them?

One of the challenges I faced was achieving consistent edge quality on complex glass shapes. To overcome this, I worked with the engineering team to develop custom tooling and techniques that allowed me to maintain high precision and accuracy even on intricate designs.

Another challenge was meeting tight deadlines on large orders. To address this, I implemented a lean manufacturing process that streamlined the edging workflow and reduced production time without compromising quality.

6. How do you stay up-to-date on the latest advancements in glass edging technology?

I actively participate in industry conferences, workshops, and online forums to learn about new techniques and technologies. I also collaborate with manufacturers and suppliers to gain insights into the latest advancements and innovations in glass edging machinery and materials.

Additionally, I regularly review technical articles, research papers, and industry publications to stay informed about the latest developments in the field.

7. What is your experience with different types of glass, such as float glass, laminated glass, and tempered glass?

- Float Glass: I have extensive experience in edging float glass, which is the most common type of glass used in windows, mirrors, and other applications. I am familiar with the properties and characteristics of float glass, and I know how to achieve high-quality edges on this material.

- Laminated Glass: I have also worked with laminated glass, which is composed of two or more layers of glass bonded together with a plastic interlayer. I understand the unique challenges of edging laminated glass, such as preventing delamination and ensuring a smooth, consistent finish.

- Tempered Glass: I have experience in edging tempered glass, which is a type of safety glass that is stronger and more resistant to breakage than regular glass. I am aware of the special precautions that must be taken when edging tempered glass to avoid damaging the material.

8. How do you handle customer inquiries and complaints related to glass edging?

- Professional and Courteous: I always maintain a professional and courteous demeanor when interacting with customers.

- Active Listening: I actively listen to the customer’s concerns and try to understand their needs and expectations.

- Problem-Solving: I work with the customer to identify the root cause of the issue and develop a solution that meets their requirements.

- Timely Response: I respond to customer inquiries and complaints promptly and efficiently.

- Follow-Up: I follow up with the customer to ensure that the issue has been resolved to their satisfaction.

9. What are your strengths and weaknesses as a Glass Edger?

Strengths

- Attention to Detail: I am highly detail-oriented and take pride in producing high-quality edges on every project.

- Expertise in Different Glass Types: I have extensive experience in edging various types of glass, including float glass, laminated glass, and tempered glass.

- Problem-Solving Skills: I am able to quickly identify and resolve any issues that may arise during the edging process.

- Efficiency and Accuracy: I work efficiently and accurately to meet tight deadlines without compromising quality.

Weaknesses

- Experience with Specialized Edging Techniques: While I am proficient in various edging techniques, I am still developing my experience with some specialized edging techniques, such as CNC edging.

10. Why are you interested in this Glass Edger position with our company?

I am eager to join your company as a Glass Edger because I am impressed by your reputation for producing high-quality glass products. I am confident that my skills and experience would be a valuable asset to your team.

I am particularly interested in the opportunity to work on challenging and complex projects. I am eager to learn from experienced professionals and contribute to the production of exceptional glass products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Edger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Edger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Edgers are responsible for operating and maintaining glass edging machines, which are used to shape and polish the edges of glass sheets. They must also be able to identify and correct defects in the glass, such as scratches, cracks, or bubbles. The accuracy and precision required for this job makes attention to detail and a steady hand essential.

1. Machine Operation

Glass Edgers must be able to operate glass edging machines safely and efficiently. This includes loading and unloading the machine, setting up the machine for different types of glass, and monitoring the machine during operation.

- Load and unload glass sheets from the machine.

- Set up the machine for different types of glass, such as float glass, tempered glass, or laminated glass.

- Monitor the machine during operation to ensure that it is cutting and polishing the glass correctly.

2. Quality Control

Glass Edgers must be able to identify and correct defects in the glass. This includes inspecting the glass for scratches, bubbles, cracks, or other imperfections. They must also be able to correct these defects using hand tools or power tools.

- Inspect the glass for scratches, bubbles, cracks, or other imperfections.

- Correct defects using hand tools or power tools.

3. Machine Maintenance

Glass Edgers must be able to perform basic maintenance on glass edging machines. This includes cleaning and lubricating the machine, and replacing worn or damaged parts.

- Clean and lubricate the machine.

- Replace worn or damaged parts.

- Troubleshoot and repair minor problems with the machine.

4. Safety

Glass Edgers must be able to work safely around glass edging machines. This includes wearing appropriate safety gear, such as safety glasses, gloves, and earplugs. They must also be aware of the hazards associated with working with glass, such as sharp edges and broken glass.

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Be aware of the hazards associated with working with glass.

- Follow all safety procedures.

Interview Tips

To ace your interview for a glass edger position, you should be prepared to answer questions about your experience with glass edging machines, your quality control procedures, and your safety practices. You should also be able to demonstrate your attention to detail and your ability to work independently.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, LinkedIn, Glassdoor, and other online resources.

2. Practice answering common interview questions

There are a number of common interview questions that you can expect to be asked in an interview for a glass edger position. These questions include:

- Tell me about your experience with glass edging machines.

- What are your quality control procedures?

- What are your safety practices?

- Why are you interested in this position?

- What are your strengths and weaknesses?

You can practice answering these questions by writing out your responses or by rehearsing with a friend or family member.

3. Be prepared to demonstrate your skills

In addition to answering interview questions, you may also be asked to demonstrate your skills. This could involve operating a glass edging machine, inspecting a piece of glass, or correcting a defect. Be prepared to demonstrate your skills in a clear and concise manner.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time.

5. Ask questions

At the end of your interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glass Edger role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.