Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

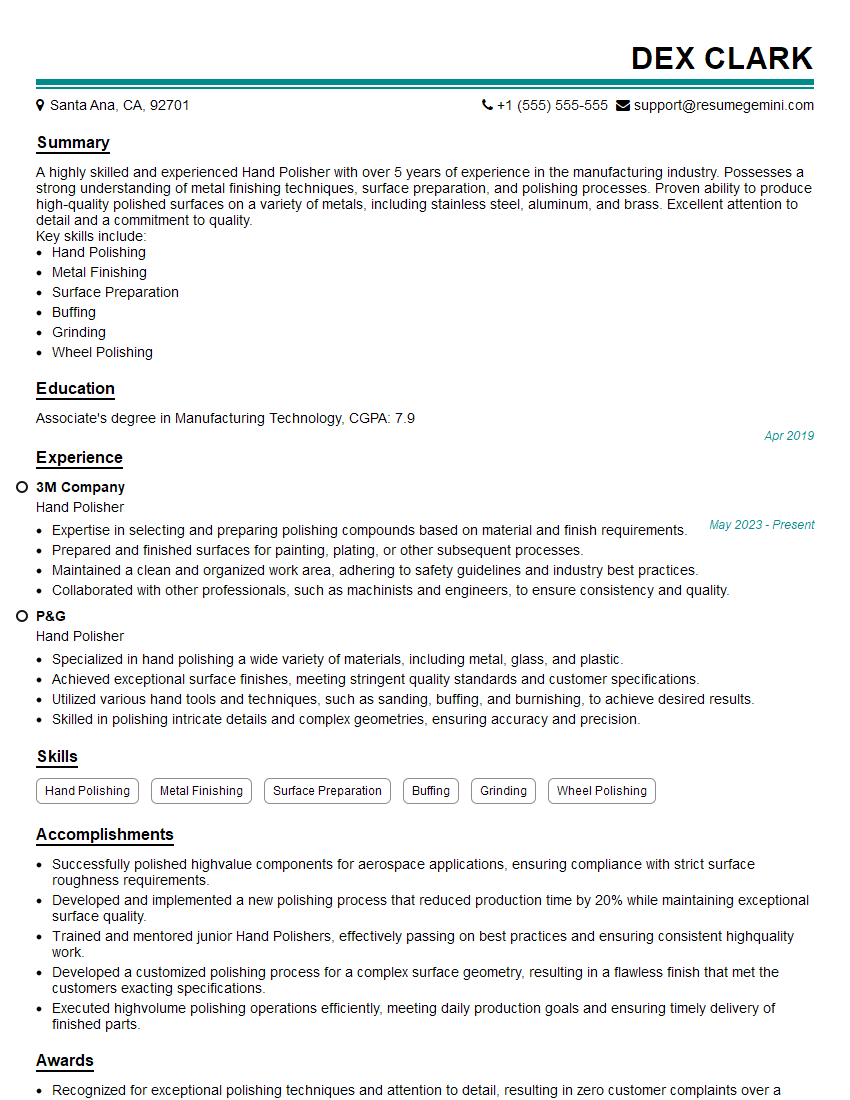

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Polisher

1. Explain the process of hand polishing a metal surface?

- Surface preparation: Cleaning and degreasing the surface to remove any contaminants.

- Selecting the right abrasive: Choosing the appropriate abrasive based on the desired finish.

- Lubrication: Applying a lubricant to reduce friction and prevent scratches.

- Polishing: Using hand tools or power tools to apply pressure and move the abrasive over the surface in a circular motion.

- Rinsing and drying: Removing any remaining abrasive or lubricant from the surface.

2. What are the different types of hand polishers?

- Rotary hand polishers: Electric or pneumatic tools that spin a polishing head at high speeds.

- Orbital hand polishers: Tools that move the polishing head in a circular motion while also spinning it.

- Dual-action hand polishers: A combination of rotary and orbital motion for a more efficient polish.

- Buffing wheels: Hand-held tools used for finer polishing and buffing.

- Polishing cloths: Soft cloths used for hand polishing small areas or applying polishing compounds.

3. How do you determine the right abrasive for hand polishing a particular material?

- Material hardness: Harder materials require coarser abrasives, while softer materials need finer abrasives.

- Desired finish: The desired level of gloss or reflectivity influences the abrasive selection.

- Surface condition: If the surface is heavily scratched or damaged, a coarser abrasive may be needed initially.

- Manufacturer’s recommendations: Consulting the manufacturer’s guidelines for specific materials and finishes.

- Trial and error: Experimenting with different abrasives to find the optimal result for the particular material and finish.

4. What safety precautions should be taken when hand polishing?

- Wear appropriate protective gear: Gloves, safety glasses, and a respirator to protect against dust and debris.

- Maintain a clean and well-ventilated work area: To avoid inhaling harmful particles.

- Avoid excessive pressure: Applying too much pressure can damage the surface or cause injuries.

- Secure the workpiece: Ensure the item being polished is securely fastened to prevent accidents.

- Use caution with rotary hand polishers: Keep hands clear of the spinning head and always unplug the tool when not in use.

5. How do you achieve a high-quality mirror finish using hand polishing techniques?

- Start with a smooth surface: Ensure the surface is free of scratches and imperfections before polishing.

- Use a fine polishing compound: Select a compound specifically designed for achieving a mirror finish.

- Polish in multiple passes: Repeat the polishing process several times, gradually using finer abrasives to refine the finish.

- Apply consistent pressure: Maintain a steady and even pressure while polishing to avoid uneven results.

- Pay attention to detail: Focus on polishing all areas of the surface, including corners and edges, to ensure a uniform finish.

6. How do you troubleshoot common problems encountered during hand polishing?

- Surface scratches: Use a finer abrasive or polish in multiple passes to remove scratches.

- Uneven finish: Ensure consistent pressure and polishing technique throughout the surface.

- Insufficient gloss: Use a polishing compound with a higher abrasive content or polish for longer to achieve a higher gloss.

- Discoloration: Use a polishing compound that is compatible with the material being polished to avoid discoloration.

- Safety concerns: Always wear protective gear and follow safety precautions to prevent injuries or damage to equipment.

7. What are the key factors that influence the efficiency of hand polishing?

- Abrasive selection: Choosing the appropriate abrasive based on material and desired finish.

- Polishing technique: Maintaining consistent pressure, speed, and motion during polishing.

- Lubrication: Using the right lubricant to reduce friction and prevent scratches.

- Workpiece preparation: Cleaning and degreasing the surface prior to polishing.

- Skill and experience: The skill and experience of the hand polisher can significantly impact efficiency and quality.

8. How do you handle delicate or intricate surfaces during hand polishing?

- Use soft polishing cloths or brushes: Avoid using abrasive materials that could damage delicate surfaces.

- Apply light pressure: Be gentle and avoid excessive pressure to prevent scratching or bending the material.

- Protect edges and corners: Pay attention to polishing around edges and corners to prevent chipping or damaging the material.

- Use a magnification device: If necessary, use a magnifying glass or microscope to inspect and polish intricate details.

- Practice and patience: Delicate surfaces require patience and a steady hand. Practice on similar materials before polishing actual delicate pieces.

9. How do you assess the quality of a hand-polished surface?

- Visual inspection: Examine the surface for scratches, imperfections, or unevenness.

- Gloss measurement: Use a gloss meter to measure the level of gloss or reflectivity achieved.

- Touch test: Run your fingers over the surface to feel for any roughness or ridges.

- Microscopic analysis: If necessary, use a microscope to inspect the surface for any defects or imperfections.

- Customer feedback: Obtain feedback from customers or end-users to assess the satisfaction with the quality of the polished surface.

10. How do you stay updated with the latest techniques and advancements in hand polishing?

- Attend industry workshops and conferences.

- Read trade publications and online resources.

- Network with other hand polishers and experts.

- Experiment with new products and techniques.

- Stay informed about advancements in materials and equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hand Polisher is responsible for polishing and finishing a variety of surfaces using hand tools. Key job responsibilities include:1. Surface Preparation

Ensuring the surfaces to be polished are clean, dry, and free of any imperfections or debris.

2. Polishing and Buffing

Using hand-held tools, such as buffers and polishers, to bring out the shine and smoothness of the surfaces.

3. Removing Excess Material

Trimming and removing any excess material or burrs created during the polishing process, ensuring a clean and professional finish.

4. Quality Control

Inspecting polished surfaces for defects or imperfections, ensuring they meet the required standards and customer specifications.

Interview Tips

To ace an interview for a Hand Polisher position, consider the following tips:1. Research the Company and Industry

Demonstrate your knowledge of the company’s history, products, and industry trends to show your interest and understanding of the field.

2. Highlight Relevant Skills and Experience

Emphasize your experience in hand polishing, buffing, and finishing techniques. Quantify your achievements, providing specific examples of your work.

3. Demonstrate Attention to Detail

Share examples of your meticulous approach to surface preparation and quality control, showcasing your commitment to delivering high-quality results.

4. Be Prepared to Discuss Safety Protocols

Discuss your understanding of safety regulations and procedures relevant to hand polishing, including the proper use of equipment and materials.

5. Show Enthusiasm and Motivation

Express your passion for the craft and your desire to contribute to the team’s success. Highlight your willingness to learn and take on challenges.

6. Prepare Questions for the Interviewer

Ask thoughtful questions about the company’s expectations, ongoing projects, and opportunities for professional development. This shows your interest in the position and your commitment to your career.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Polisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Polisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.