Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Casing Fluid Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Casing Fluid Tender so you can tailor your answers to impress potential employers.

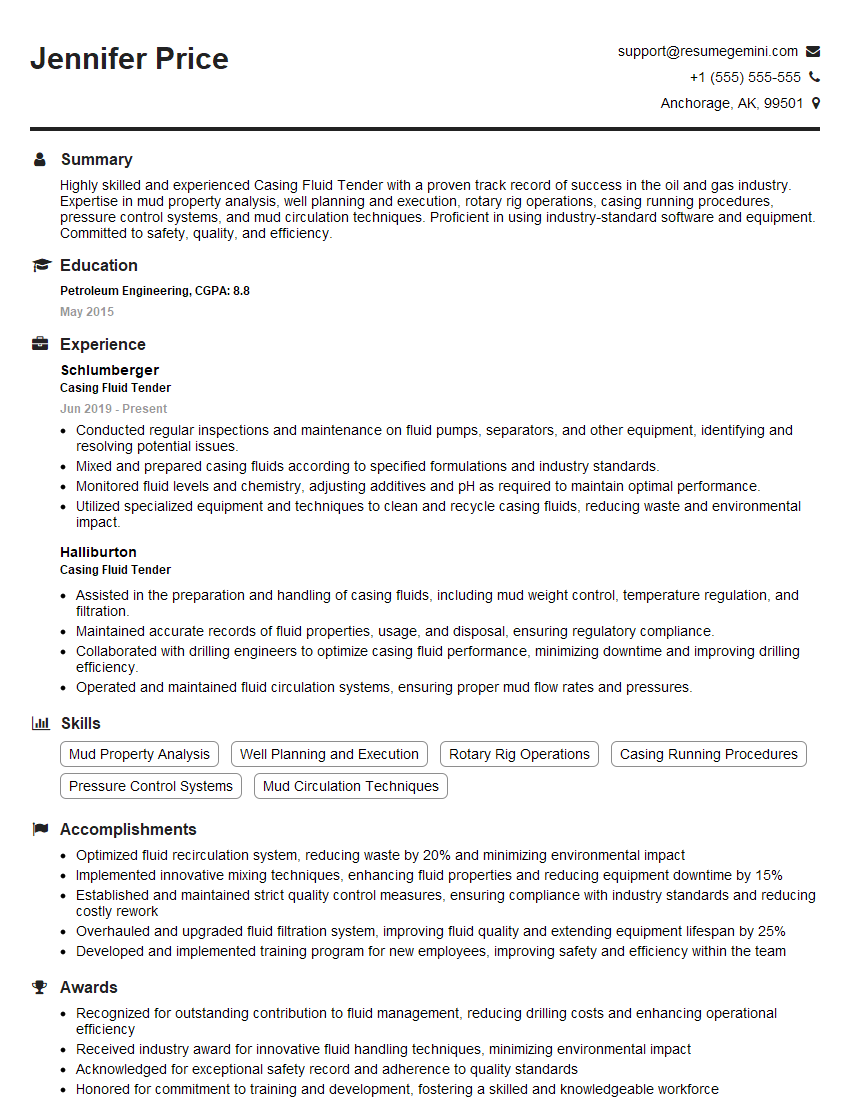

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Fluid Tender

1. What are the primary responsibilities of a Casing Fluid Tender?

- Maintain and clean casing fluid tanks, pumps, and other associated equipment

- Monitor casing fluid levels and report any discrepancies

2. How do you ensure the proper maintenance of casing fluid equipment?

Inspection

- Visually inspect equipment for leaks, damage, or wear

- Check fluid levels, pressure, and temperature regularly

Maintenance

- Clean and lubricate equipment as per manufacturer’s recommendations

- Perform minor repairs or adjustments

3. What are the potential hazards associated with casing fluid operations, and how do you mitigate them?

- Chemical hazards: Wear appropriate PPE, handle fluids safely

- Pressure hazards: Ensure proper pressure regulation, avoid overpressurization

- Slips, trips, and falls: Keep work area clean and free of obstructions

4. What is the importance of casing fluid properties, and how do you ensure they meet specifications?

- Control well pressure, prevent blowouts

- Lubricate and cool drilling tools

- Test fluid properties regularly, adjust additives as needed

5. How do you handle emergencies related to casing fluid operations?

- Remain calm and follow established procedures

- Identify source of problem and take corrective action

- Report emergencies to supervisor or designated personnel

6. What are the different types of casing fluids, and when are they used?

- Water-based muds: General purpose, low cost

- Oil-based muds: High lubricity, stable at high temperatures

- Synthetic-based muds: Environmentally friendly, versatile

7. How do you calculate the volume of casing fluid required for a given drilling operation?

- Determine hole diameter and depth

- Calculate annular volume (hole volume – pipe volume)

- Add a safety factor for losses

8. What is the importance of casing fluid filtration, and how is it achieved?

- Removes contaminants that can damage equipment or affect fluid properties

- Filters achieved through various methods, such as shakers, cyclones, or vacuum filters

9. What is the role of additives in casing fluids, and how do you select the appropriate ones?

- Additives enhance fluid properties: weight, viscosity, lubricity

- Selection based on specific drilling conditions and fluid requirements

10. How do you coordinate with drilling crews and other rig personnel to ensure efficient casing fluid operations?

- Communicate fluid needs and schedules

- Resolve any issues or concerns promptly

- Participate in safety briefings and drills

11. Describe a challenging situation you faced as a Casing Fluid Tender and how you overcame it.

- Describe the specific situation

- Explain the steps taken to resolve the issue

- Highlight any skills or knowledge used

12. How do you stay updated on the latest advancements and best practices in casing fluid operations?

- Attend industry conferences and workshops

- Read technical articles and manuals

- Consult with experienced colleagues

13. Why are you interested in this Casing Fluid Tender position and our company specifically?

- Express enthusiasm for the role and industry

- Highlight skills and experience relevant to the position

- Research the company’s reputation and contributions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Fluid Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Fluid Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Casing Fluid Tender is responsible for maintaining and operating the casing fluid system on a drilling rig. They are responsible for ensuring that the casing fluid is properly circulated and maintained at the correct temperature and viscosity. They also monitor the system for any leaks or problems and perform any necessary repairs.

1. Monitor the casing fluid system

The Casing Fluid Tender monitors the casing fluid system to ensure that it is operating properly. They check the fluid level, temperature, and viscosity, and make any necessary adjustments.

2. Perform routine maintenance

The Casing Fluid Tender performs routine maintenance on the casing fluid system, including greasing the bearings, checking the belts, and cleaning the filters.

3. Troubleshoot and repair problems

The Casing Fluid Tender troubleshoots and repairs any problems that occur with the casing fluid system. They may need to replace a pump, repair a leak, or clean a filter.

4. Operate the casing fluid system

The Casing Fluid Tender operates the casing fluid system during drilling operations. They start and stop the pumps, and adjust the flow rate and pressure of the fluid.

Interview Tips

To ace an interview for a Casing Fluid Tender position, you will need to be able to demonstrate that you have the necessary knowledge and skills. You will also need to be able to show that you are a team player and that you are able to work independently.

1. Research the company and the position

Before you go on an interview, it is important to do your research. Learn about the company and the specific position you are applying for. This will show the interviewer that you are interested in the job and that you have taken the time to prepare.

2. Practice answering common interview questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions beforehand so that you can deliver your answers confidently and clearly.

3. Highlight your relevant experience and skills

When answering interview questions, be sure to highlight your relevant experience and skills. For example, if you have experience in operating casing fluid systems, be sure to mention this. You should also highlight any other skills that would be relevant to the position, such as your ability to work independently or your ability to troubleshoot problems.

4. Be prepared to talk about your safety procedures

Safety is a top priority in the oil and gas industry. When interviewing for a Casing Fluid Tender position, be prepared to talk about your safety procedures. For example, you may be asked about your experience in working with hazardous materials or your knowledge of safe operating procedures.

5. Ask questions

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you are interested in the job and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Fluid Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!