Feeling lost in a sea of interview questions? Landed that dream interview for Fire Protection Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fire Protection Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

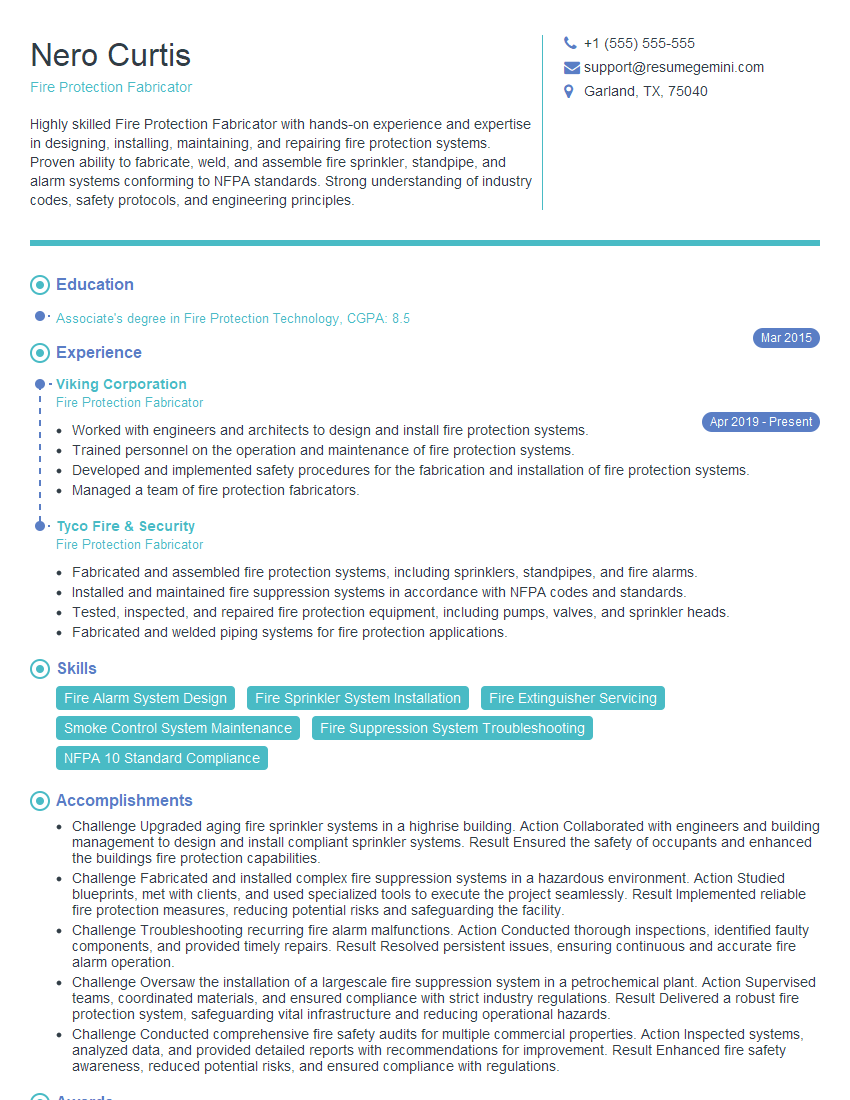

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fire Protection Fabricator

1. How would you determine the appropriate type of fire protection fabric for a specific application?

To determine the appropriate type of fire protection fabric, I would consider the following factors:

- The specific fire hazards present

- The temperature and duration of the fire exposure

- The physical and chemical properties of the fabric

- The cost and availability of the fabric

2. What are the different types of fire protection fabrics that you have experience with, and what are their respective advantages and disadvantages?

Types of Fabrics

- Fiberglass – Advantages: High temperature resistance, low smoke generation. Disadvantages: Can be abrasive, limited flexibility.

- Kevlar – Advantages: High tensile strength, flame-resistant. Disadvantages: Expensive, can be damaged by moisture.

- Nomex – Advantages: Flame-resistant, moisture-resistant. Disadvantages: Lower tensile strength, more expensive.

Advantages

- Increased protection from fire and heat

- Improved safety and reduced risk of injury

- Compliance with building codes and safety regulations

Disadvantages

- Increased cost compared to non-fire-resistant fabrics

- Reduced breathability and comfort in certain applications

- Special care and maintenance requirements to ensure optimal performance

3. describe the process of installing a fire protection fabric, from start to finish

The process of installing a fire protection fabric typically involves the following steps:

- Preparation: Preparing the surface by cleaning and removing any debris or obstacles.

- Cutting: Cutting the fabric to the desired size and shape using specialized tools.

- Hanging: Hanging the fabric using appropriate hardware such as hooks, clips, or adhesives.

- Securing: Securing the fabric in place by tightening the hardware and ensuring it is securely fastened.

- Inspection: Inspecting the installation to ensure it meets the required standards and is fully functional.

4. What is the importance of maintaining fire protection fabrics, and what are the recommended maintenance procedures?

Maintaining fire protection fabrics is crucial to ensure their effectiveness and longevity. Recommended maintenance procedures include:

- Regular inspection: Regularly inspecting the fabrics for any signs of damage, wear, or deterioration.

- Cleaning: Cleaning the fabrics according to the manufacturer’s instructions to remove dirt, dust, or contaminants that may affect their performance.

- Repair: Promptly repairing any tears, holes, or other damage to maintain the integrity of the fabric.

- Replacement: Replacing the fabrics when they reach the end of their lifespan or when they can no longer provide adequate protection.

5. What are the different types of fire protection systems, and how do they differ in their application and effectiveness?

Types of Systems

- Active Systems: Designed to detect and extinguish fires using devices like sprinklers, alarms, and smoke detectors.

- Passive Systems: Focus on preventing the spread of fire and providing structural stability during a fire, such as fire-rated walls, doors, and compartments.

Application and Effectiveness

- Active Systems: Effective for detecting and suppressing fires in their early stages. Require regular maintenance and testing.

- Passive Systems: Provide a barrier against fire spread and allow for safe evacuation. Do not require active intervention but need proper design and installation.

6. How do you stay up-to-date with the latest advancements in fire protection technology and best practices?

To stay current with advancements in fire protection technology and best practices, I engage in the following activities:

- Industry Events: Attending conferences, workshops, and exhibitions to learn about new products, techniques, and regulations.

- Technical Publications: Reading industry journals, white papers, and technical articles to stay informed about the latest research and developments.

- Continuing Education: Pursuing additional training programs or certifications to enhance my skills and knowledge.

- Professional Affiliations: Being an active member of professional organizations and participating in committees to connect with experts and exchange ideas.

7. What are the challenges you have faced as a Fire Protection Fabricator, and how have you overcome them?

Some challenges I have faced as a Fire Protection Fabricator include:

Challenges

- Complex Project Requirements: Meeting specific fire codes and performance standards while ensuring aesthetic appeal.

- Material Limitations: Working with flame-resistant fabrics that may have limitations in terms of flexibility, durability, and cost.

- Project Deadlines: Balancing the need for precision and quality with tight project deadlines.

How I have overcome them

- Collaboration: Working closely with designers, architects, and engineers to understand project requirements and find innovative solutions.

- Research and Development: Exploring new materials and techniques to enhance the performance and aesthetics of fire protection fabrics.

- Effective Planning: Developing detailed project plans and timelines to ensure timely completion without compromising quality.

8. what are the essential qualities of a successful Fire Protection Fabricator?

Essential qualities of a successful Fire Protection Fabricator include:

- Technical Expertise: Strong knowledge of fire protection materials, building codes, and industry best practices.

- Problem-Solving Skills: Ability to identify and resolve complex issues related to design, installation, and maintenance.

- Attention to Detail: Meticulous approach to ensure precision in measurements, cutting, and installation.

- Communication Skills: Effective communication with clients, architects, engineers, and other professionals.

- Teamwork and Collaboration: Ability to work effectively as part of a team and contribute to the success of projects.

9. How do you prioritize safety in your workplace, and what measures do you take to minimize risks?

Prioritizing safety in my workplace is paramount. I take the following measures to minimize risks:

- Regular Safety Inspections: Conducting regular inspections to identify potential hazards and ensure compliance with safety regulations.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE for all employees, including gloves, safety glasses, and respirators.

- Safety Training: Conducting comprehensive safety training programs for all employees, covering topics such as fire safety, hazardous materials handling, and emergency procedures.

- Hazard Communication: Implementing a hazard communication program to ensure employees are aware of potential hazards and proper handling procedures.

- Emergency Response Plans: Developing and practicing emergency response plans to ensure a coordinated and effective response in case of an incident.

10. What is your understanding of sustainability as it relates to Fire Protection Fabrics, and how do you incorporate sustainable practices into your work?

Sustainability in Fire Protection Fabrics refers to using materials and processes that minimize environmental impact while maintaining performance and safety.

Incorporating Sustainable Practices

- Material Selection: Choosing fabrics made from recycled or renewable materials, reducing waste and conserving resources.

- Waste Reduction: Implementing waste reduction strategies, such as optimizing cutting patterns and recycling fabric scraps.

- Energy Efficiency: Using energy-efficient equipment and lighting systems in the fabrication process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fire Protection Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fire Protection Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fire Protection Fabricator is accountable for the fabrication and installation of fire protection systems, adhering to industry standards and regulations. Their responsibilities encompass:

1. Fabrication and Installation

- Fabricate and assemble fire protection systems, including sprinklers, fire alarms, and smoke detectors.

- Install and connect these systems in commercial and residential buildings.

2. System Maintenance and Repair

- Inspect and maintain fire protection systems to ensure proper functioning.

- Troubleshoot and repair any malfunctions or defects.

3. Blueprint Reading and Interpretation

- Interpret and follow blueprints and schematics for system design and installation.

- Ensure installations comply with building codes and fire safety regulations.

4. Customer Collaboration and Safety

- Collaborate with clients to determine specific fire protection needs.

- Adhere to safety protocols and maintain a safe work environment.

Interview Tips

To ace the interview for a Fire Protection Fabricator position, candidates should focus on showcasing their:

1. Technical Expertise

- Highlight experience in fabricating and installing fire protection systems.

- Demonstrate knowledge of industry standards and building codes.

2. Blueprint Reading Skills

- Emphasize proficiency in interpreting blueprints and schematics.

- Provide examples of how you have used blueprints to successfully complete projects.

3. Problem-Solving Abilities

- Share experiences in troubleshooting and repairing fire protection systems.

- Describe how you have overcome challenges and ensured the proper functioning of systems.

4. Customer Service Orientation

- Convey a strong customer-centric approach.

- Provide examples of how you have effectively communicated with clients and met their needs.

5. Safety Consciousness

- Stress your commitment to maintaining a safe work environment.

- Highlight any safety training or certifications you possess.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fire Protection Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!