Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Caustic Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

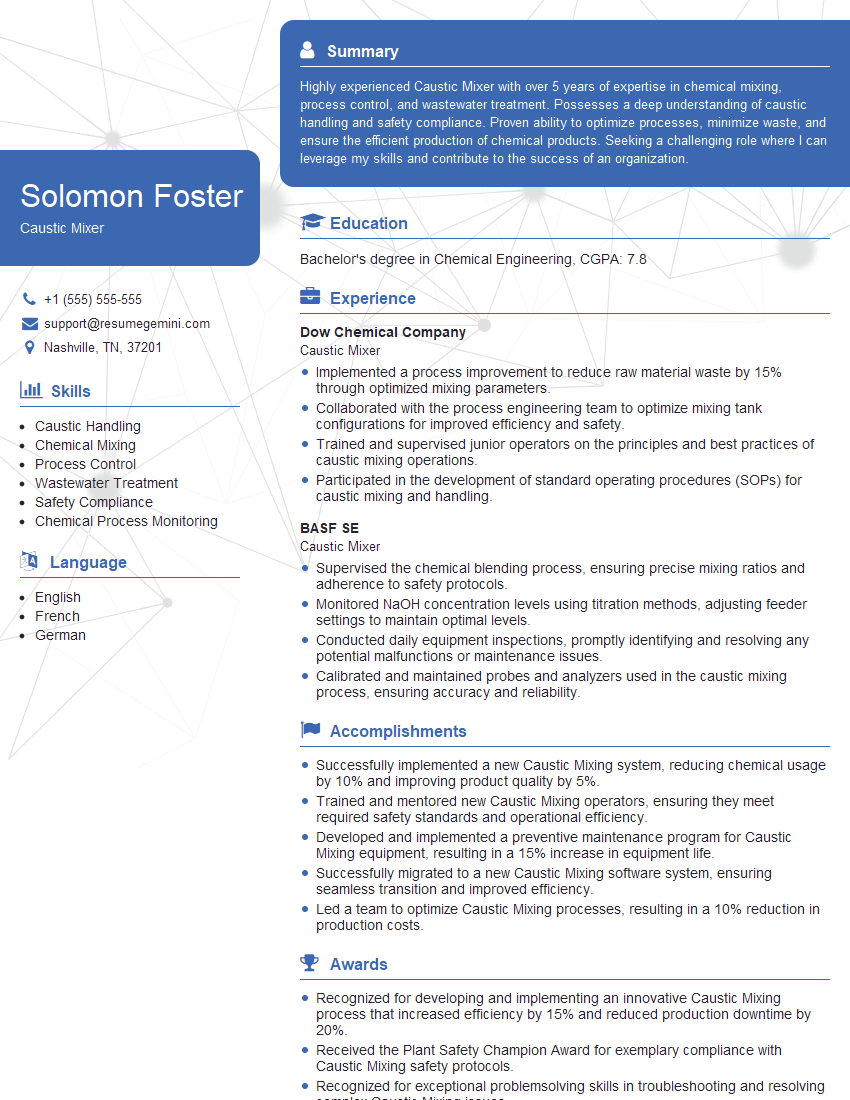

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Caustic Mixer

1. Explain the process of mixing caustic soda solutions?

The process of mixing caustic soda solutions involves several key steps:

- Safety Precautions: It is crucial to wear appropriate personal protective equipment (PPE) and ensure proper ventilation before handling caustic soda.

- Preparation of Stock Solution: The first step is to prepare a concentrated stock solution of caustic soda by dissolving a specific amount of sodium hydroxide pellets in water.

- Dilution: The stock solution is then diluted to the desired concentration by adding a calculated amount of water.

- Mixing: The stock solution and water are gradually mixed using a mechanical agitator to ensure complete homogenization.

- pH Monitoring: The pH of the solution is closely monitored during mixing to ensure it meets the specified target.

- Cooling: The mixing process generates heat, so it is important to cool the solution if necessary to maintain the desired temperature.

- Transfer and Storage: Once the solution is mixed and cooled, it is transferred to the appropriate storage containers.

2. Describe the properties and applications of caustic soda solutions?

Properties of Caustic Soda Solutions:

- High pH (alkaline)

- Corrosive to metals and tissues

- Hygroscopic (absorbs moisture from the air)

- Decomposes organic matter

- Reacts with acids to form salts

Applications of Caustic Soda Solutions:

- Soap and detergent manufacturing

- Paper production

- Food processing

- Textile processing

- Pharmaceutical industry

- Water treatment

- Metal cleaning

3. What are the safety concerns associated with handling caustic soda solutions?

Handling caustic soda solutions requires proper safety measures due to its corrosive and hazardous nature:

- Chemical Burns: Contact with caustic soda solutions can cause severe chemical burns to skin and eyes.

- Inhalation: Inhaling caustic soda fumes can irritate the respiratory system.

- Eye Damage: Eye contact can lead to permanent damage or blindness.

- Fire and Explosion Hazard: Caustic soda solutions can react violently with certain chemicals and organic materials, potentially causing fires or explosions.

4. How do you calibrate and maintain the equipment used in caustic soda mixing processes?

Calibration and maintenance of equipment are crucial for accurate and safe mixing:

- pH Meter Calibration: Calibrate the pH meter regularly using standard solutions to ensure accurate pH readings.

- Agitator Maintenance: Inspect and maintain the agitator regularly to ensure proper mixing and prevent failure.

- Piping and Valves: Regularly check the condition of pipes and valves to prevent leaks and ensure safe operation.

- Safety Equipment: Inspect and maintain safety equipment, such as eye wash stations and ventilation systems, to ensure they are in good working order.

5. Describe the quality control procedures for caustic soda mixing?

Quality control measures ensure the consistent production of high-quality caustic soda solutions:

- Raw Material Inspection: Inspect incoming raw materials (caustic soda pellets and water) to verify their quality and purity.

- Mixing Process Monitoring: Monitor the mixing process to ensure adherence to specified parameters (pH, temperature, concentration).

- Product Testing: Conduct regular testing of the final product to verify its pH, concentration, and other quality attributes.

- Documentation: Maintain accurate records of all mixing processes, including raw material usage, mixing conditions, and product testing results.

6. What are the common challenges encountered in caustic soda mixing and how do you overcome them?

Common challenges and their solutions:

- pH Control: Maintaining the desired pH can be challenging due to external factors. Use precise pH monitoring and adjust the mixing process accordingly.

- Uniform Mixing: Ensuring complete homogenization can be difficult. Optimize the mixing time and agitator design to achieve the desired uniformity.

- Temperature Control: Mixing can generate heat. Implement cooling mechanisms to prevent excessive temperature rise.

- Safety Hazards: Always prioritize safety by wearing appropriate PPE, using well-ventilated areas, and following proper handling procedures.

7. How do you handle deviations from the specified mixing parameters?

Handling deviations is essential for maintaining product quality:

- Identify the Cause: Determine the root cause of the deviation through investigation.

- Corrective Actions: Implement appropriate corrective actions to bring the process back within specifications.

- Preventative Measures: Analyze the deviation and identify ways to prevent similar issues in the future.

- Documentation: Record the deviation, corrective actions, and preventative measures for tracking and improvement purposes.

8. Explain the importance of adhering to safety protocols when handling caustic soda solutions?

Adhering to safety protocols is crucial to prevent accidents and protect personnel:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, goggles, and respirators, to minimize exposure.

- Proper Handling: Follow established procedures for handling caustic soda solutions, including proper dilution and mixing techniques.

- Emergency Preparedness: Be familiar with emergency protocols, including spill cleanup and medical treatment.

- Training and Education: Ensure that all personnel involved in handling caustic soda are adequately trained and educated on safety protocols.

9. How do you handle and dispose of waste generated from caustic soda mixing processes?

Proper waste management is essential for environmental protection:

- Waste Segregation: Segregate caustic soda waste from other waste streams to prevent contamination.

- Neutralization: Neutralize caustic soda waste before disposal to reduce its corrosivity.

- Disposal Methods: Follow local regulations and guidelines for the safe disposal of neutralized caustic soda waste.

- Record Keeping: Maintain accurate records of waste generation, handling, and disposal to ensure compliance and traceability.

10. Describe your experience in optimizing caustic soda mixing processes for improved efficiency?

Optimization strategies for improved efficiency:

- Process Automation: Implement automated controls to streamline the mixing process and reduce manual labor.

- Agitator Optimization: Design and select agitators that provide efficient mixing while minimizing energy consumption.

- Data Analysis: Analyze process data to identify areas for improvement and implement changes to enhance efficiency.

- Continuous Improvement: Regularly review and evaluate the mixing process to identify opportunities for further optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Caustic Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Caustic Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Caustic Mixers play a vital role in maintaining the quality and consistency of a variety of products, ranging from paper and textiles to chemicals and food additives. Their primary responsibility is to mix caustic soda (sodium hydroxide) with other chemicals and raw materials to create solutions with specific concentrations and properties.

1. Chemical Mixing and Preparation

The primary task of a Caustic Mixer is to prepare and mix caustic soda solutions according to specified formulas and procedures. They must have a thorough understanding of chemical properties and safety protocols to ensure accurate mixing and prevent accidents.

- Weigh, measure, and dispense caustic soda and other chemicals accurately.

- Operate mixing equipment, such as tanks, agitators, and pumps, to combine ingredients.

- Monitor temperature, pH levels, and other critical parameters to maintain solution quality.

2. Quality Control and Testing

Caustic Mixers are responsible for ensuring the quality of the solutions they produce. They conduct various tests, such as titration and pH measurements, to verify that the solutions meet the required specifications.

- Perform quality control tests to ensure product consistency and compliance with standards.

- Calibrate and maintain testing equipment to ensure accuracy and reliability.

- Document and record test results to maintain quality records and traceability.

3. Equipment Maintenance and Calibration

Caustic Mixers must maintain and calibrate the equipment they use to ensure optimal performance and prevent downtime. They may also be responsible for cleaning and sanitizing equipment to prevent contamination.

- Inspect, clean, and maintain mixing tanks, agitators, pumps, and other equipment.

- Calibrate and verify the accuracy of measuring devices, such as scales and pH meters.

- Identify and troubleshoot equipment malfunctions and take corrective actions.

4. Safety and Compliance

Caustic soda is a hazardous chemical, so Caustic Mixers must adhere to strict safety protocols to protect themselves and others. They must also be familiar with environmental regulations and ensure that waste products are disposed of properly.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators.

- Follow established safety procedures for handling and storing caustic soda.

- Dispose of waste products and chemicals in compliance with environmental regulations.

Interview Tips

Preparing adequately for an interview is crucial. Here are some tips to help you ace your Caustic Mixer interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and culture. Visit their website, read industry news, and connect with employees on LinkedIn to gain insights into their operations. Understand the specific responsibilities and requirements of the Caustic Mixer position to tailor your answers accordingly.

2. Highlight Relevant Experience and Skills

Emphasize your experience in chemical mixing, quality control, and equipment maintenance. If you have prior experience working with caustic soda or other hazardous chemicals, mention it explicitly. Showcase your ability to handle these materials safely and efficiently.

3. Prepare for Technical Questions

Be prepared to answer questions about chemical properties, mixing procedures, and quality control techniques. Practice explaining how you would handle specific scenarios, such as equipment malfunctions or spills, to demonstrate your problem-solving abilities.

4. Practice Common Interview Questions

Anticipate general interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Practice delivering concise and engaging answers that highlight your qualifications and enthusiasm for the position.

5. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer during the interview. This shows that you are engaged, curious, and eager to learn more about the company and the role. Questions about safety protocols, industry trends, or opportunities for professional development are appropriate.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Caustic Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.