Are you gearing up for an interview for a Metal Bonding Crib Attendant position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Bonding Crib Attendant and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

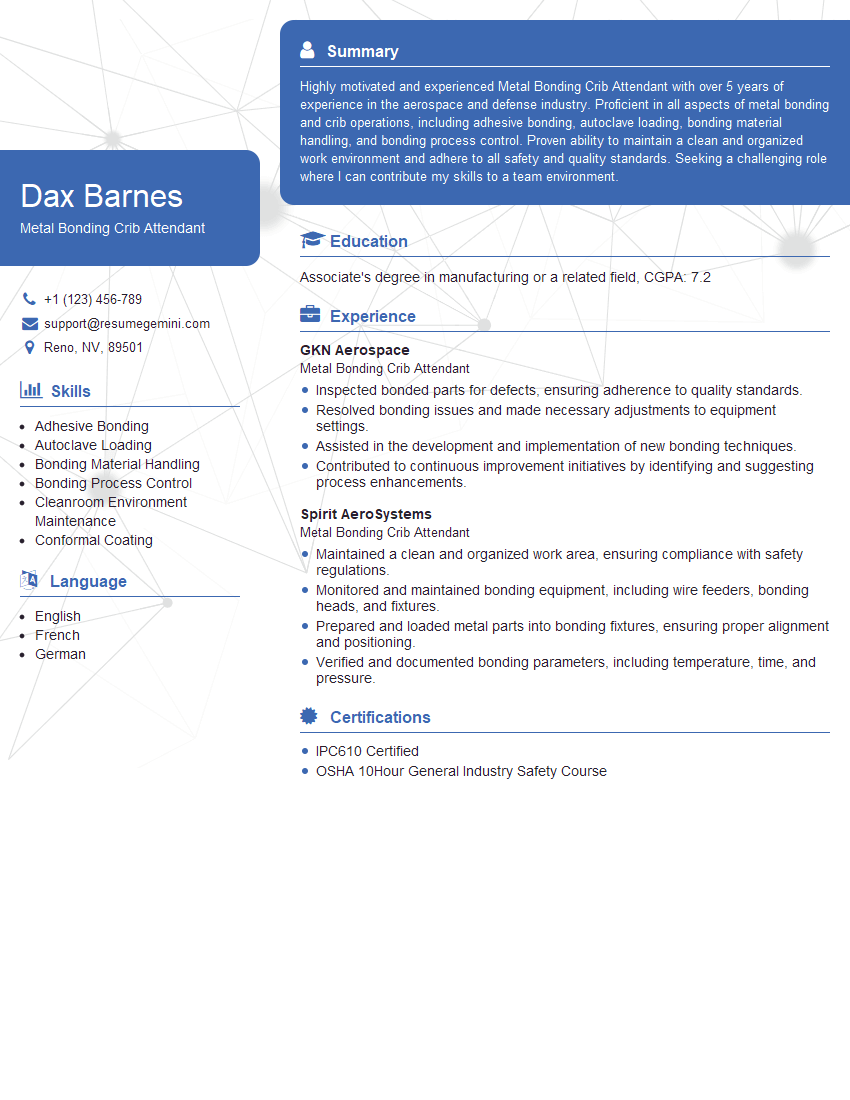

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Bonding Crib Attendant

1. What are the key responsibilities of a Metal Bonding Crib Attendant?

As a Metal Bonding Crib Attendant, I would be expected to perform a variety of tasks to support the metal bonding process. These responsibilities would include:

- Loading and unloading metal parts onto the bonding machine

- Monitoring the bonding process to ensure that it is proceeding correctly

- Inspecting bonded parts to ensure that they meet quality standards

- Maintaining the cleanliness of the bonding area

- Following safety procedures to ensure a safe work environment

2. What are the safety precautions you must follow when working with metal bonding equipment?

Personal Protective Equipment

- Wear gloves, safety glasses, and a face shield to protect against chemical splashes and flying debris.

- Wear protective clothing, such as a lab coat or apron, to protect against skin exposure to chemicals.

- Wear appropriate footwear with slip-resistant soles.

Equipment Safety

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

- Use the equipment only for its intended purpose.

- Do not operate equipment if it is damaged or malfunctioning.

Chemical Safety

- Read and understand the Safety Data Sheets (SDSs) for all chemicals used.

- Handle and store chemicals in accordance with the SDSs.

- Dispose of chemicals properly.

3. How do you ensure the quality of bonded parts?

To ensure the quality of bonded parts, I would follow a set of quality control procedures. These procedures would include:

- Inspecting parts visually for any defects

- Using measuring tools to ensure that parts meet specifications

- Testing parts to ensure that they meet performance requirements

- Maintaining records of all quality control inspections and tests

4. How do you troubleshoot and resolve problems with the metal bonding process?

If I encounter problems with the metal bonding process, I would follow a systematic approach to troubleshooting and resolution. This approach would include:

- Identifying the problem

- Investigating the cause of the problem

- Developing and implementing a solution

- Verifying that the solution has resolved the problem

5. What are the different types of metal bonding processes?

The four main metal bonding processes are:

- Soldering – Involves melting a lower-melting-point metal (solder) into the joint between two higher-melting-point metals.

- Brazing – Similar to soldering, but uses a higher-melting-point filler metal.

- Welding – Involves melting the base metals and adding a filler metal to form a joint.

- Adhesive bonding – Uses an adhesive to bond two surfaces together.

6. What are the strengths and weaknesses of each type of metal bonding process?

The strengths and weaknesses of each type of metal bonding process are as follows:

Soldering

- Strengths: Low cost, easy to use, can be used on a variety of metals

- Weaknesses: Not as strong as other bonding methods, can be susceptible to corrosion

Brazing

- Strengths: Stronger than soldering, more resistant to corrosion

- Weaknesses: More expensive than soldering, requires higher temperatures

Welding

- Strengths: Strongest bonding method, can be used on a variety of metals

- Weaknesses: Most expensive bonding method, requires specialized equipment

Adhesive bonding

- Strengths: Can be used on a variety of materials, including those that cannot be welded or soldered

- Weaknesses: Not as strong as other bonding methods, can be susceptible to environmental factors

7. What are the different types of metal bonding adhesives?

The different types of metal bonding adhesives include:

- Epoxy adhesives – Consist of two parts that are mixed together to form a strong, durable bond.

- Cyanoacrylate adhesives – Also known as super glue, these adhesives cure quickly and form a strong bond.

- Anaerobic adhesives – Cure in the absence of air and are often used for bonding metal parts.

- Hot melt adhesives – Are applied in a molten state and cure as they cool.

8. How do you select the right metal bonding adhesive for a specific application?

When selecting a metal bonding adhesive, several factors should be considered, including:

- The type of metals being bonded

- The strength requirements of the bond

- The environmental conditions to which the bond will be exposed

- The cost of the adhesive

9. What are the different types of metal bonding equipment?

The different types of metal bonding equipment include:

- Soldering irons – Used to melt solder and create a bond between two metal surfaces.

- Brazing torches – Used to melt brazing filler metal and create a stronger bond between two metal surfaces.

- Welding equipment – Used to melt the base metals and add filler metal to create a joint.

- Adhesive dispensing equipment – Used to apply adhesive to metal surfaces.

10. What are the safety precautions that must be followed when using metal bonding equipment?

When using metal bonding equipment, several safety precautions must be followed, including:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a face shield.

- Using equipment only in well-ventilated areas.

- Following the manufacturer’s instructions for safe operation.

- Storing equipment in a safe and secure location.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Bonding Crib Attendant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Bonding Crib Attendant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Bonding Crib Attendant is responsible for maintaining a clean and safe work environment in the metal bonding facility. They also provide support to metal bonding operators by ensuring that all necessary materials and tools are available.

1. Ensures a clean work environment

In order to maintain a clean work environment, the crib attendant must:

- Sweep and mop floors

- Dust surfaces

- Empty trash cans

- Clean and disinfect work surfaces

2. Maintains a safe work environment

The crib attendant must also take steps to maintain a safe work environment, including:

- Keeping aisles clear of obstacles

- Ensuring that all equipment is in good working order

- Reporting any safety hazards to supervisors

3. Provides support to metal bonding operators

In addition to maintaining the work environment, the crib attendant also provides support to metal bonding operators by:

- Issuing tools and materials

- Assisting operators with troubleshooting

- Keeping track of inventory

- Ordering new supplies

4. Other duties

The crib attendant may also be responsible for other duties, such as:

- Assisting with loading and unloading materials

- Performing quality control checks

- Training new employees

Interview Tips

To prepare for an interview for a Metal Bonding Crib Attendant position, you should do the following:

1. Research the company

This will help you understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview.

3. Prepare questions to ask the interviewer

This will show the interviewer that you are interested in the position and the company.

4. Dress professionally

This will make a good impression on the interviewer and show that you are serious about the position.

Next Step:

Now that you’re armed with the knowledge of Metal Bonding Crib Attendant interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Bonding Crib Attendant positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini