Are you gearing up for an interview for a Resin Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Resin Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

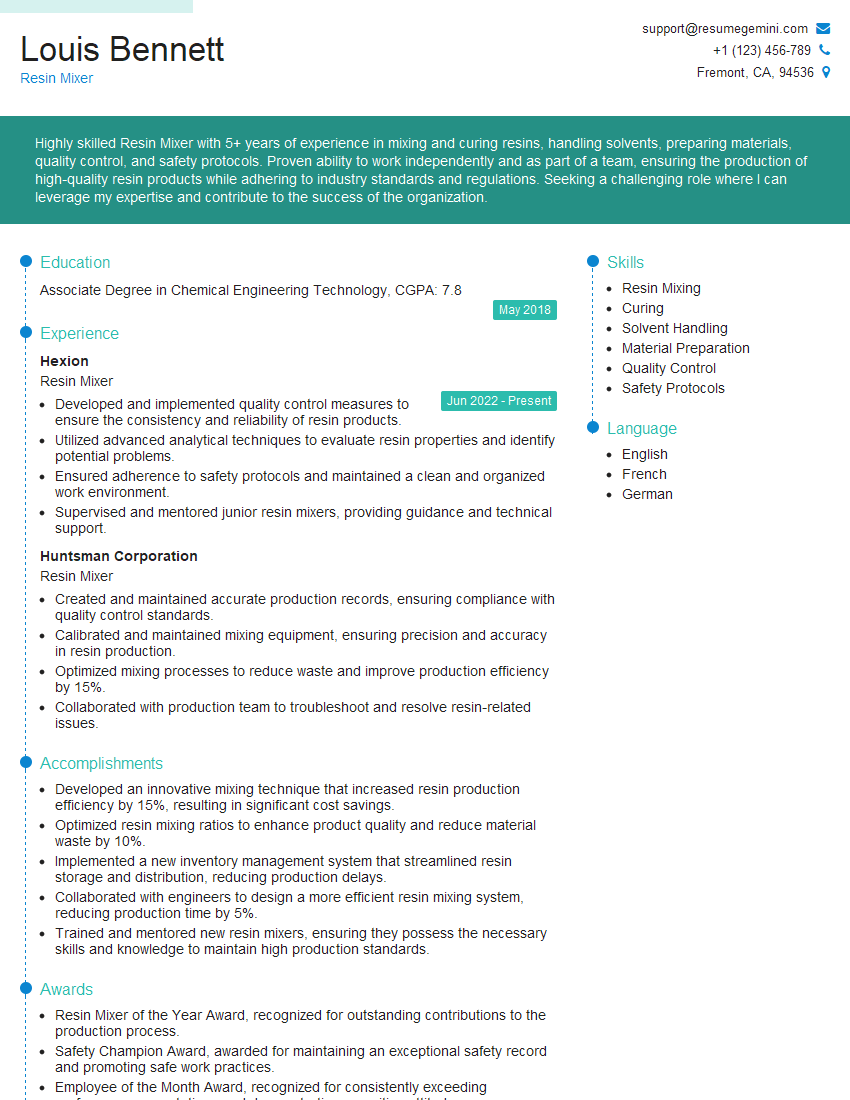

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resin Mixer

1. Explain the process of mixing resins.

- Prepare the necessary materials, including the resin, hardener, and mixing tools.

- Measure the correct proportions of resin and hardener according to the manufacturer’s instructions.

- Mix the resin and hardener thoroughly until a uniform consistency is achieved.

- Degas the mixed resin by vacuuming or using a centrifugal degassing machine to remove any air bubbles.

2. What are the different types of resins and their applications?

- Polyester resins: Used in fiberglass reinforced plastics, boat hulls, and automotive parts.

- Epoxy resins: High-performance resins used in adhesives, coatings, and composite materials.

- Acrylic resins: Durable and weather-resistant resins used in clear coatings, plastics, and adhesives.

- Phenolic resins: Heat-resistant resins used in electrical components, laminates, and adhesives.

3. How do you ensure the quality of the mixed resin?

- Use high-quality raw materials from reputable suppliers.

- Follow the manufacturer’s mixing instructions precisely.

- Test the mixed resin for viscosity, gel time, and curing properties.

- Maintain proper storage and handling procedures to prevent contamination and premature curing.

4. What are the safety precautions to be taken while working with resins?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a respirator.

- Ensure proper ventilation to avoid inhalation of fumes.

- Handle flammable resins with caution and store them in a safe area.

- Avoid skin contact with uncured resins as they can cause irritation and allergic reactions.

5. Describe the process of applying mixed resin.

- Prepare the surface by cleaning and roughening it to enhance adhesion.

- Apply the mixed resin using a brush, roller, or spray gun.

- Ensure even distribution and proper thickness of the resin layer.

- Allow the resin to cure according to the manufacturer’s specifications.

6. What are the techniques used to troubleshoot common problems with mixed resins?

- Resin not curing: Check the resin’s viscosity, gel time, and proper mixing ratio.

- Air bubbles in the resin: Degas the resin thoroughly before application.

- Resin too thick: Add a small amount of thinner or solvent to reduce viscosity.

- Resin too thin: Add more resin or thickener to increase viscosity.

7. Explain the importance of maintaining accurate records for resin mixing.

- Track material usage for cost control and inventory management.

- Ensure consistency in the resin’s quality and performance.

- Facilitate troubleshooting and identify potential issues.

- Meet regulatory requirements and safety standards.

8. Describe the equipment used in the resin mixing process.

- Mixers: Industrial mixers used to blend the resin and hardener.

- Degassing machines: Equipment used to remove air bubbles from the mixed resin.

- Dispensing equipment: Used to accurately measure and dispense the mixed resin.

- Safety equipment: PPE, ventilation systems, and fire extinguishers.

9. What are the key challenges in resin mixing and how do you overcome them?

- Ensuring accurate mixing ratios: Use precise measuring tools and follow the manufacturer’s guidelines.

- Preventing contamination: Maintain a clean work environment and use dedicated mixing equipment.

- Controlling resin viscosity: Use the appropriate thinner or thickener to achieve the desired consistency.

- Safety concerns: Implement proper ventilation, wear PPE, and handle flammable resins with caution.

10. How do you stay updated with the latest advancements in resin mixing technology?

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Consult with equipment manufacturers and resin suppliers.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resin Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resin Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Resin Mixers are responsible for preparing and mixing resin materials used in the manufacturing process, ensuring proper consistency and quality.

1. Material Preparation and Mixing

The primary duty of a Resin Mixer is to prepare and mix various resin materials according to specifications.

- Accurately measure and weigh raw materials using scales, measuring cups, or other tools.

- Follow established mixing procedures to combine materials thoroughly using mixers, blenders, or other equipment.

2. Quality Control and Testing

Resin Mixers are responsible for ensuring the quality of the mixed resin materials.

- Perform tests to verify the proper consistency and viscosity of the resin using viscometers or other instruments.

- Inspect mixed materials for any irregularities, impurities, or deviations from specifications.

3. Equipment Maintenance and Troubleshooting

Resin Mixers are required to maintain and troubleshoot equipment used in the mixing process.

- Clean and maintain mixing equipment to ensure proper operation and prevent contamination.

- Identify and resolve minor equipment malfunctions, such as blockages or leaks.

4. Health and Safety Compliance

Resin Mixers must adhere to safety protocols and regulations in the workplace.

- Wear appropriate personal protective equipment (PPE) when handling hazardous materials.

- Follow established procedures for the safe disposal of chemicals and waste.

Interview Tips

Preparing for an interview as a Resin Mixer requires a combination of technical knowledge and effective communication skills.

1. Research the Company and Position

Familiarize yourself with the company’s products, industry, and specific requirements for the Resin Mixer role.

- Visit the company’s website to gather information about their operations, values, and current projects.

- Review the job description thoroughly to understand the exact responsibilities and qualifications.

2. Highlight Technical Skills and Experience

Emphasize your proficiency in the following areas:

- Mixing and preparation of resin materials, including knowledge of different types of resins and additives.

- Quality control testing procedures and equipment, such as viscometers and other instruments.

- Equipment maintenance and troubleshooting, including cleaning and minor repairs.

3. Demonstrate Quality Consciousness

Convey your commitment to producing high-quality resin products by highlighting your attention to detail and adherence to specifications.

- Describe specific instances where you implemented quality control measures or resolved issues with mixed materials.

- Emphasize your ability to identify potential problems and take proactive steps to prevent defects.

4. Emphasize Safety and Compliance

Showcase your understanding of safety protocols and regulations in the manufacturing industry.

- Explain your knowledge of proper PPE usage and waste disposal procedures.

- Share examples of how you have implemented safety measures in previous roles.

5. Practice and Prepare

Prepare for common interview questions by practicing your answers and rehearsing your presentation.

- Consider questions about your technical skills, experience, and safety protocols.

- Prepare examples and anecdotes that demonstrate your qualifications and highlight your suitability for the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Resin Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Resin Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.