Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roof Cement and Paint Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

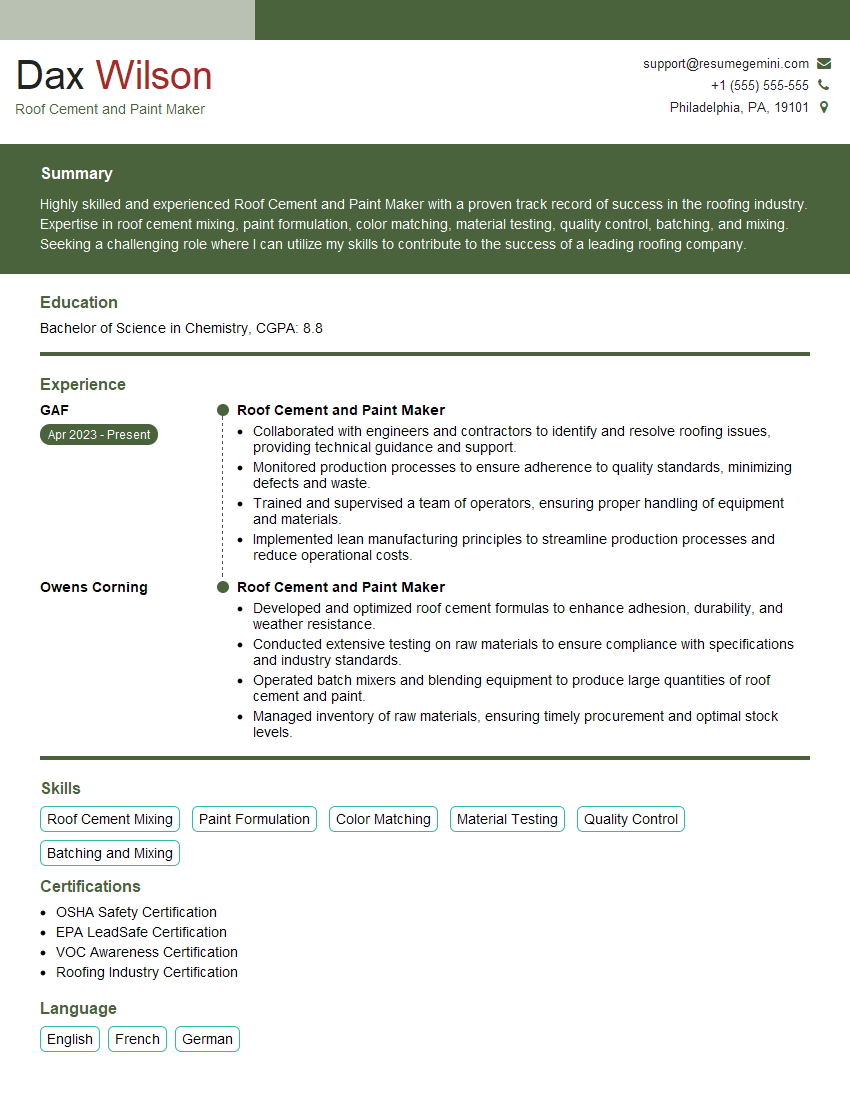

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roof Cement and Paint Maker

1. What are the key properties of a high-quality roof cement?

- Excellent adhesion to various roofing materials, including asphalt, metal, and concrete.

- High tensile strength to resist cracking and tearing.

- Waterproof and weather-resistant to protect the roof from moisture and UV radiation.

- Flexibility to allow for expansion and contraction of the roof due to temperature changes.

- Durability to withstand extreme weather conditions and last for an extended period.

2. Describe the process of manufacturing roof cement.

Raw Material Selection

- Select high-quality asphalt, resins, and fillers to ensure desired properties.

- Determine the appropriate ratio of ingredients based on the desired performance.

Mixing and Blending

- Combine the raw materials in a mixer and blend thoroughly until a homogeneous mixture is obtained.

- Control temperature and mixing time to achieve the desired consistency and workability.

Molding and Packaging

- Pour the blended mixture into molds of various shapes and sizes.

- Allow the cement to cure and solidify before packaging for distribution.

3. What are the different types of roof paint available, and how do their properties vary?

- Asphalt-based Paint: Durable, waterproof, and resistant to UV radiation. Ideal for roofs exposed to harsh weather conditions.

- Acrylic-based Paint: Flexible, crack-resistant, and available in a wide range of colors. Suitable for metal and asphalt roofs.

- Elastomeric Paint: Highly elastic and reflective, reducing roof temperatures. Can be applied to various roofing materials.

- Silicone-based Paint: Resistant to extreme temperatures, UV radiation, and chemicals. Ideal for commercial and industrial buildings.

4. Explain the factors to consider when selecting a roof paint.

- Roof Material: Choose paint compatible with the roofing material (asphalt, metal, concrete, etc.).

- Climate Conditions: Consider the weather conditions in the area where the roof is located.

- Desired Properties: Determine the specific properties required, such as durability, flexibility, or reflectivity.

- Maintenance Requirements: Select paint that is easy to apply and maintain over time.

5. Describe the application process for roof paint.

- Surface Preparation: Clean the roof surface, remove dirt, debris, and loose paint.

- Primer Application (Optional): Use a primer to improve paint adhesion and durability.

- Paint Application: Apply two thin coats of paint, allowing each coat to dry thoroughly before applying the next.

- Drying Time: Allow the paint to cure according to the manufacturer’s instructions before allowing foot traffic.

6. What are the common defects that can occur in roof coatings and how to prevent them?

- Cracking and Peeling: Ensure proper surface preparation, use flexible paint, and avoid over-application.

- Blistering: Avoid painting on wet or damp surfaces, use a compatible primer, and ensure adequate ventilation.

- Fading and Chalking: Select paint with UV-resistant pigments, apply multiple coats, and clean the roof regularly.

- Mildew and Algae Growth: Use paints with fungicides or mildewcides, and keep the roof clean and free of debris.

7. What are the safety precautions to consider when working with roof cement and paint?

- Wear appropriate protective gear, including gloves, eye protection, and respiratory mask.

- Work in a well-ventilated area to avoid inhaling fumes.

- Handle materials carefully to prevent spills and accidents.

- Follow manufacturer’s instructions for safe handling and disposal of products.

8. Describe the different types of roofing substrates and their compatibility with different roof paints.

- Asphalt Shingles: Compatible with asphalt-based, acrylic, and elastomeric paints.

- Metal Roofing: Compatible with acrylic, silicone, and high-temperature paints.

- Concrete Roofs: Compatible with acrylic, elastomeric, and silicone paints.

- TPO and PVC Membranes: Compatible with elastomeric and silicone paints specifically designed for these materials.

9. Explain the role of the primer in a roof coating system.

- Improves adhesion between the roof surface and the paint.

- Seals minor imperfections and cracks in the roof.

- Protects the roof from moisture and other environmental factors.

- Enhances the durability and longevity of the paint system.

10. Describe the latest advancements in roof cement and paint technology.

- Self-healing Roof Coatings: Can automatically seal cracks and tears, extending the life of the roof.

- Cool Roof Coatings: Reflect sunlight and reduce roof temperatures, improving energy efficiency.

- Anti-fouling Coatings: Resist the growth of mold, algae, and other microorganisms.

- Sustainable Roof Coatings: Made from environmentally friendly materials and have low VOC emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roof Cement and Paint Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roof Cement and Paint Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roof Cement and Paint Makers are responsible for producing and maintaining the materials used in the construction and repair of roofs. They may work in a factory setting or on-site, mixing and applying materials to create waterproof and protective surfaces.

1. Mixing and Preparing Materials

Roof Cement and Paint Makers must be able to mix and prepare materials according to specifications. This includes mixing cement, sand, and water to create roof cement, as well as mixing and applying paint to roofs.

- Measure and mix raw materials according to formulas

- Operate mixing equipment to combine ingredients

2. Applying Materials to Roofs

Roof Cement and Paint Makers must be able to apply materials to roofs in a safe and effective manner. This includes using trowels, brushes, and rollers to apply cement and paint to roofs.

- Apply roof cement to seams, joints, and flashings

- Paint roofs to protect them from the elements

3. Inspecting and Repairing Roofs

Roof Cement and Paint Makers must be able to inspect and repair roofs for damage. This includes identifying areas of wear and tear, and making repairs using appropriate materials.

- Inspect roofs for damage, such as cracks or leaks

- Repair roofs using appropriate materials and techniques

4. Maintaining Equipment

Roof Cement and Paint Makers must be able to maintain their equipment in good working order. This includes cleaning and lubricating equipment, and making minor repairs as needed.

- Clean and lubricate equipment

- Make minor repairs to equipment

Interview Tips

Preparing for an interview for a Roof Cement and Paint Maker position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position.

- Visit the company’s website

- Read industry publications

- Talk to people in your network who work in the industry

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions

- Tailor your answers to the specific job requirements

- Practice your answers with a friend or family member

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the field. Be prepared to talk about your past projects, your skills, and your accomplishments. It is also helpful to bring a portfolio of your work to the interview.

- Highlight your experience in mixing and applying roofing materials

- Discuss your knowledge of different types of roofing materials

- Share examples of your work that demonstrate your skills

4. Be Prepared to Answer Questions About Your Safety Knowledge

Roofing work can be dangerous, so the interviewer will want to know that you are aware of the hazards and that you take safety seriously. Be prepared to answer questions about your safety training and experience.

- Discuss your understanding of fall protection

- Explain how you would handle hazardous materials

- Share examples of your safety practices on previous jobs

Next Step:

Now that you’re armed with the knowledge of Roof Cement and Paint Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Roof Cement and Paint Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini