Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Slurry Control Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

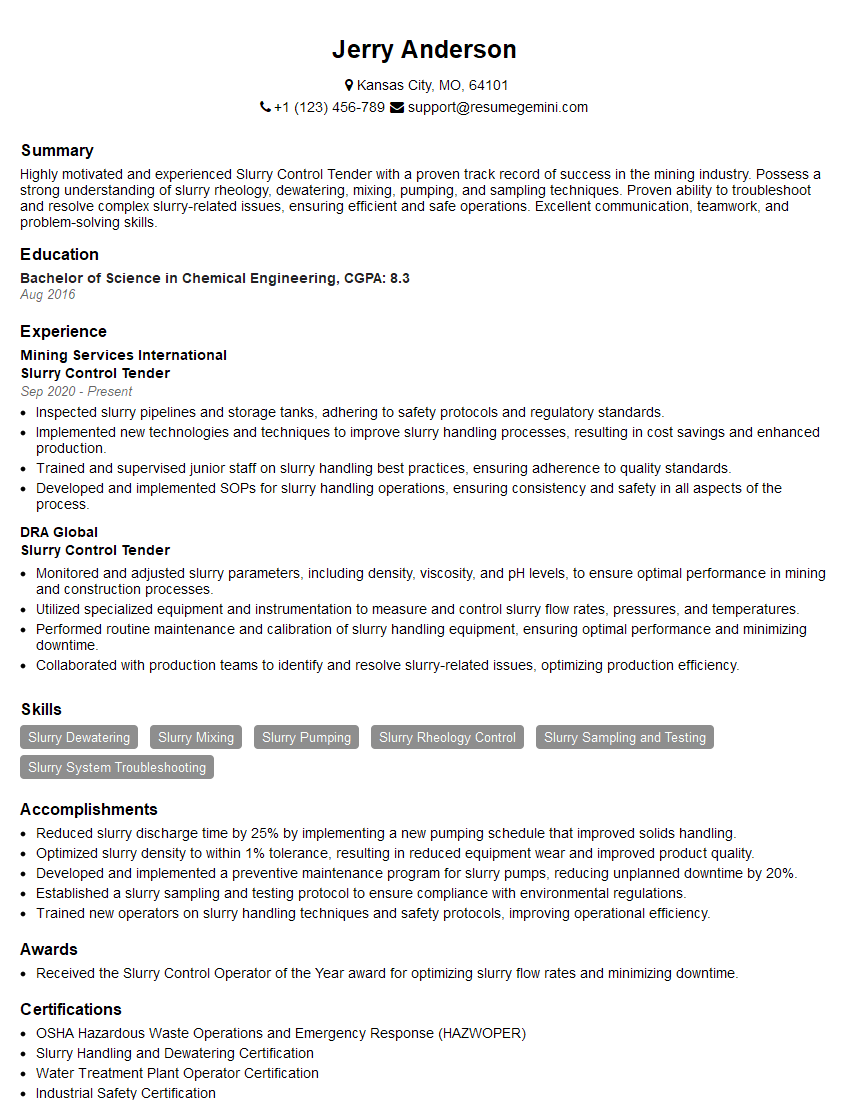

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slurry Control Tender

1. Explain the role of a Slurry Control Tender?

The primary responsibility of a Slurry Control Tender is to ensure the efficient and safe operation of the slurry handling system in a mining or mineral processing facility. This involves monitoring and controlling the flow of slurry, maintaining equipment, and ensuring compliance with environmental and safety regulations.

2. Describe the key skills and knowledge required for a Slurry Control Tender?

Technical Skills:

- Expertise in slurry handling systems, including pumps, pipelines, valves, and control instrumentation

- Proficiency in electrical and mechanical troubleshooting and repair

- Understanding of fluid mechanics and slurry behavior

Knowledge:

- Environmental regulations related to slurry disposal

- Safety procedures for working with slurry and hazardous materials

- Industry best practices for slurry management

3. How do you monitor and control the flow of slurry in a handling system?

Monitoring involves using sensors and instrumentation to track slurry flow rate, pressure, and density. Controlling the flow requires adjusting valves, pumps, and other equipment to maintain desired flow conditions. This ensures efficient slurry transfer and prevents blockages or overflows.

4. Describe the maintenance tasks involved in slurry control?

Regular maintenance is crucial for optimal system performance. It includes inspecting and cleaning pumps, pipelines, valves, and instrumentation; lubricating moving parts; and replacing worn or damaged components. This proactive approach minimizes equipment downtime and ensures the safe and efficient operation of the slurry handling system.

5. How do you handle emergencies or system failures in a slurry handling system?

Emergency preparedness is essential in slurry control. In the event of a system failure or spillage, the Tender must remain calm and assess the situation promptly. This involves identifying the source of the problem, isolating affected areas, and implementing emergency shutdown procedures. The Tender should also notify supervisors and initiate cleanup or repair measures to minimize potential hazards.

6. Explain the importance of environmental compliance in slurry management?

Slurry handling can potentially impact the environment if not managed responsibly. The Tender plays a crucial role in ensuring compliance with environmental regulations by monitoring and controlling slurry disposal practices. This involves proper containment of slurry, preventing spills or leaks, and adhering to waste disposal guidelines.

7. Describe the safety precautions and personal protective equipment (PPE) required for working with slurry?

Working with slurry poses potential hazards such as chemical exposure, falls, and equipment-related injuries. The Tender must be aware of potential risks and adhere to safety protocols. This includes wearing appropriate PPE (e.g., respirators, gloves, safety glasses) and following established safety procedures for handling and disposing of slurry.

8. How do you communicate effectively with colleagues and supervisors in a slurry handling operation?

Effective communication is essential for smooth and safe operations. The Tender should be able to clearly convey information, instructions, and observations to colleagues and supervisors. This includes using technical terminology, maintaining accurate records, and reporting any system issues or concerns promptly.

9. Describe your experience in troubleshooting and resolving issues in a slurry handling system?

Troubleshooting and resolving issues are critical aspects of slurry control. The Tender should demonstrate a methodical approach to problem-solving, including identifying the root cause, implementing appropriate corrective actions, and monitoring the effectiveness of the solution.

10. How do you stay updated with advancements in slurry handling technology and best practices?

The Tender should be proactive in staying abreast of industry trends and technological advancements. This involves attending conferences, reading industry publications, and participating in training programs to enhance their knowledge and skills in slurry management and control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slurry Control Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slurry Control Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Slurry Control Tender, you will be responsible for the monitoring and control of slurry systems in a mining or mineral processing operation. This involves:

1. Equipment Operation

Operate and maintain slurry pumps, pipelines, and other equipment used in the slurry system.

- Ensure that all equipment is functioning properly and efficiently.

- Troubleshoot and resolve any problems that may arise with the equipment.

2. Slurry Monitoring

Monitor the slurry flow rate, pressure, and density to ensure that the system is operating within optimal parameters.

- Take corrective actions to adjust the slurry flow rate, pressure, or density as needed.

- Maintain records of slurry flow rates, pressures, and densities.

3. System Maintenance

Perform routine maintenance and repairs on the slurry system, including pumps, pipelines, and other equipment.

- Replace worn or damaged parts.

- Lubricate and clean equipment to prevent breakdowns.

4. Health and Safety

Maintain a safe and healthy work environment by adhering to all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE).

- Follow proper lockout/tagout procedures.

Interview Tips

To prepare for your interview as a Slurry Control Tender, here are some essential tips:

1. Research the Company and Position

Familiarize yourself with the company’s operations, its products or services, and the specific responsibilities of the Slurry Control Tender role.

- Visit the company’s website and read about their mission, values, and recent news.

- Review the job description carefully and identify the key skills and qualifications required.

2. Highlight Your Relevant Experience

Emphasize your previous experience in slurry control or a related field. Quantify your accomplishments and provide specific examples of how you have contributed to the success of past projects.

- Use action verbs and industry-specific jargon to describe your responsibilities.

- Be prepared to discuss your experience in monitoring and controlling slurry systems, troubleshooting equipment problems, and performing maintenance.

3. Demonstrate Your Technical Skills

Showcase your understanding of slurry control principles, equipment operation, and maintenance procedures.

- Discuss your knowledge of slurry flow dynamics, pumping systems, and instrumentation.

- Provide examples of how you have used your technical skills to solve problems and improve efficiency.

4. Emphasize Your Safety Consciousness

Highlight your commitment to safety and your understanding of the importance of adhering to safety regulations.

- Describe your experience in following proper lockout/tagout procedures and using appropriate personal protective equipment (PPE).

- Explain how you prioritize safety in your daily work and ensure the well-being of yourself and your colleagues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slurry Control Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!