Feeling lost in a sea of interview questions? Landed that dream interview for Slurry Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Slurry Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

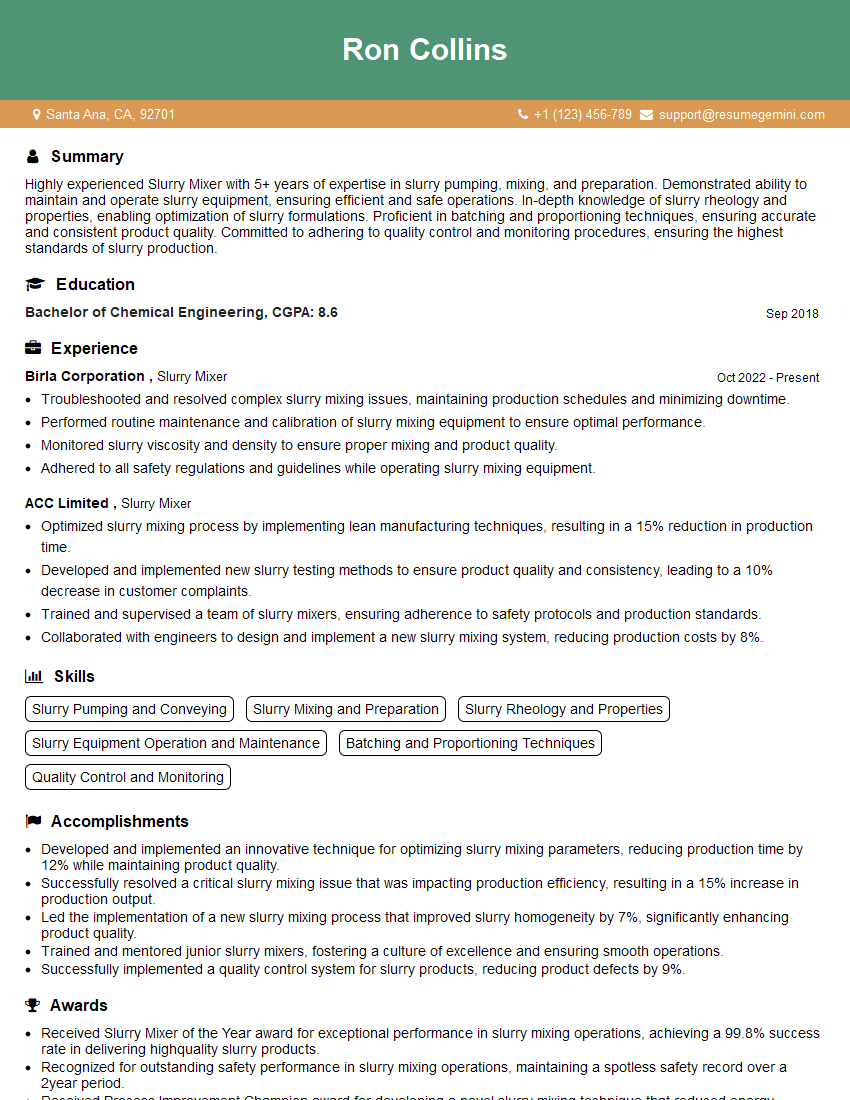

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slurry Mixer

1. How do you determine the correct water-to-cement ratio for a slurry mix?

To determine the correct water-to-cement ratio, I consider the following factors:

- Desired workability: The water content affects the workability of the slurry. A higher water content increases workability, making it easier to pump and place.

- Strength requirements: The water-to-cement ratio directly impacts the strength of the concrete. A lower water content results in a stronger mix.

- Materials used: The type and quality of cement, aggregates, and admixtures influence the optimal water-to-cement ratio.

- Environmental conditions: Temperature, humidity, and curing conditions can affect the hydration process and, therefore, the water-to-cement ratio.

2. Describe the process of preparing a slurry mix, including the equipment you would use.

Materials Mixing

- Calculate the required quantities of cement, water, aggregates, and admixtures based on the mix design.

- Add the materials to the mixer in the correct sequence to ensure proper hydration and dispersion.

Mixing Equipment

- Concrete mixer: Used to mix small to medium volumes of slurry.

- Slurry plant: Designed for high-volume production and continuous mixing of large quantities of slurry.

Mixing Procedure

- Start the mixer and gradually add water to the cement.

- Add the aggregates and any admixtures as per the mix design.

- Mix until the slurry reaches the desired consistency and homogeneity.

- Perform quality control tests, such as slump tests, to ensure the slurry meets specifications.

3. How do you troubleshoot common problems that can occur during slurry mixing, such as poor flowability or segregation?

To troubleshoot common problems during slurry mixing:

- Poor flowability:

- Check the water-to-cement ratio. Adjust it if necessary to improve workability.

- Inspect the aggregates for size and gradation. Ensure they meet the specifications.

- Segregation:

- Increase the mixing time to ensure thorough dispersion of materials.

- Consider adding a viscosity-modifying admixture to prevent separation.

4. What safety precautions must be taken when handling slurry mixes?

To ensure safety when handling slurry mixes:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and respirators.

- Avoid contact with the skin and eyes. If contact occurs, rinse immediately with plenty of water.

- Handle slurry in well-ventilated areas to prevent inhalation of dust or fumes.

- Dispose of slurry properly according to environmental regulations.

- Follow all safety guidelines and protocols established at the workplace.

5. How do you maintain and calibrate the equipment used in slurry mixing?

To maintain and calibrate equipment used in slurry mixing:

- Mixers:

- Inspect and clean mixers regularly to remove any buildup or debris.

- Check for any wear or damage to the blades or other components.

- Calibrate the mixer to ensure accurate mixing speeds and volumes.

- Slurry pumps:

- Monitor pump performance and pressure regularly.

- Replace worn or damaged impellers and seals.

- Testing equipment:

- Calibrate testing equipment, such as slump cones and flow tables, according to standard procedures.

6. How do you manage and optimize the production of slurry mixes in a large-scale operation?

To manage and optimize slurry production in a large-scale operation:

- Planning and scheduling: Plan production runs and ensure adequate raw materials are available.

- Quality control: Implement strict quality control measures at all stages of production.

- Equipment maintenance: Regularly maintain and calibrate equipment to ensure efficient operation.

- Process optimization: Analyze production data and identify areas for improvement, such as reducing mixing time or optimizing water usage.

- Inventory management: Manage raw material and finished product inventory to prevent shortages or overstocking.

7. How do you stay up-to-date with the latest developments in slurry mixing technology and best practices?

To stay up-to-date with the latest developments in slurry mixing:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with experts in the field.

- Participate in online forums and discussion groups.

- Seek opportunities for professional development and training.

8. How do you ensure that the slurry mix meets the required specifications and performance criteria?

To ensure that the slurry mix meets the required specifications and performance criteria:

- Follow mix design procedures: Use proven and tested mix designs to achieve the desired properties.

- Control the quality of materials: Use high-quality cement, aggregates, and admixtures that meet industry standards.

- Monitor the mixing process: Ensure that the mixing time, water content, and other parameters are controlled within specified limits.

- Perform quality control tests: Conduct regular tests on the slurry mix, such as slump tests, flow tests, and strength tests, to verify compliance with specifications.

- Document and track results: Keep accurate records of mix designs, material properties, and test results for future reference and traceability.

9. How do you handle and resolve technical challenges or issues that may arise during slurry mixing?

When handling technical challenges or issues during slurry mixing:

- Identify the root cause: Determine the underlying cause of the issue through analysis and troubleshooting.

- Research and consult: Seek information and guidance from technical experts, literature, and industry resources.

- Develop solutions: Propose and implement practical solutions that address the root cause and improve the mixing process.

- Monitor and evaluate: Track the effectiveness of implemented solutions and make adjustments as needed to optimize performance.

10. How do you contribute to continuous improvement and innovation in slurry mixing practices?

To contribute to continuous improvement and innovation in slurry mixing practices:

- Identify areas for improvement: Analyze existing processes and identify opportunities for optimization.

- Research and explore new technologies: Stay informed about emerging technologies and their potential applications in slurry mixing.

- Collaborate with experts: Engage with researchers, industry professionals, and suppliers to share knowledge and foster innovation.

- Implement and test new ideas: Experiment with new techniques and materials to evaluate their effectiveness and potential benefits.

- Share knowledge and best practices: Disseminate findings and lessons learned through presentations, publications, and industry events.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slurry Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slurry Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Slurry Mixer is a crucial member of the mining or construction team responsible for producing the slurry mixture used in various industrial processes. This role requires a combination of technical expertise and practical skills. Here are the key job responsibilities of a Slurry Mixer:

1. Slurry Preparation and Mixing

The primary task of a Slurry Mixer is to prepare and mix slurry according to specified proportions and specifications. They need to:

- Measure and weigh dry and liquid components accurately

- Load ingredients into the mixing equipment

- Operate and maintain mixing equipment to achieve desired consistency and composition

- Monitor mixing parameters such as temperature, flow rates, and viscosity

2. Equipment Maintenance and Inspection

Slurry Mixers are responsible for ensuring the proper functioning of mixing equipment. They need to:

- Perform regular maintenance and inspections of mixing equipment, including pumps, pipelines, and tanks

- Troubleshoot and resolve equipment issues promptly

- Adhere to safety protocols and regulations related to equipment operation

3. Quality Control and Process Monitoring

Slurry Mixers play a vital role in maintaining the quality of slurry. They need to:

- Conduct regular quality checks to ensure slurry meets specifications

- Monitor and adjust mixing parameters to maintain consistent slurry composition

- Document mixing procedures and quality control data

4. Safety and Environmental Compliance

Slurry Mixers prioritize safety and environmental compliance in their work. They need to:

- Follow established safety protocols and wear appropriate personal protective equipment

- Handle and dispose of hazardous materials responsibly

- Comply with environmental regulations and guidelines

Interview Tips

To ace the interview for a Slurry Mixer position, it’s essential to prepare thoroughly. Here are some interview tips:

1. Research the Company and Position

Before the interview, research the company and the specific Slurry Mixer position. This will help you understand the company’s culture, values, and the roles and responsibilities of the position. Highlight how your skills and experience align with the company’s needs.

2. Practice Your Answers

Prepare your answers to common interview questions related to your skills, experience, and knowledge of the industry. Practice your answers out loud to improve your delivery and confidence. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

3. Technical Questions Preparation

For a Slurry Mixer position, expect technical questions related to slurry preparation, equipment operation, and quality control. Review basic slurry mixing principles, common equipment used, and quality control techniques. Be prepared to discuss your experience and understanding of these aspects.

4. Highlight Safety Consciousness

Emphasize your safety consciousness and commitment to following safety protocols. Discuss your experience in handling hazardous materials and adhering to environmental regulations.

5. Ask Questions

At the end of the interview, demonstrate your interest in the position by asking thoughtful questions about the company, the role, and the industry. This shows that you are engaged and eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slurry Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!