Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Soap Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

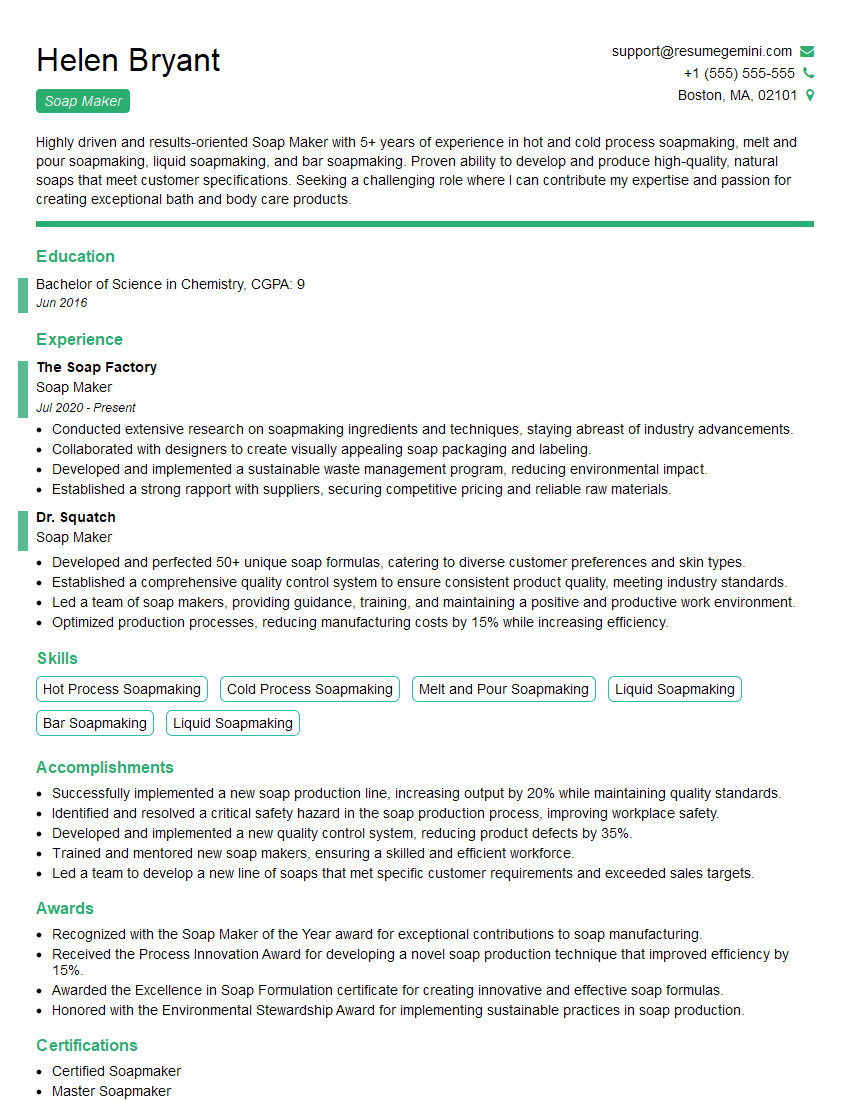

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soap Maker

1. What are the key ingredients used in soap making and explain their functions?

Some of the key ingredients used in soap making are:

- Oils and Fats: These are the main components of soap and provide the cleansing properties. Common oils used include olive oil, coconut oil, and palm oil.

- Lye (Sodium Hydroxide or Potassium Hydroxide): Lye is a strong alkali that reacts with the oils and fats to create soap through a process called saponification.

- Water: Water is used to dissolve the lye and facilitate the saponification reaction.

- Additives: Additives can be used to enhance the properties or appearance of the soap, such as essential oils for fragrance, clays for color, or exfoliants for added cleansing power.

2. Describe the saponification process and its importance in soap making

Saponification Reaction

- Saponification is a chemical reaction that occurs between fats/oils and an alkali (lye) to produce soap and glycerin.

- The reaction takes place when the lye breaks down the fatty acid chains in the fats/oils, forming salts called soap molecules.

Importance of Saponification

- Crucial for soap making as it converts fats/oils into soap, giving it the ability to cleanse and remove dirt and oils.

- Determines the quality and properties of the soap, such as its hardness, lather, and cleansing power.

3. How do you determine the right amount of lye to use in a soap recipe?

The correct amount of lye is crucial for soap making as too much can result in a harsh soap, while too little can leave the soap soft or ineffective. The amount of lye required depends on the type of fats/oils used and their saponification values.

- Saponification Value: Each oil or fat has a specific saponification value, which indicates the amount of lye required to saponify it completely.

- Lye Calculator: Online lye calculators help determine the exact amount of lye needed based on the type and quantity of fats/oils used.

- Experience and Testing: Experienced soap makers often rely on their knowledge and experimentation to adjust lye amounts for optimal results.

4. Explain the different methods of soap making and their advantages and disadvantages

Cold Process:

- Advantages: Simpler method, allows for customization, produces a more natural soap with higher glycerin content.

- Disadvantages: Longer curing time (4-6 weeks), requires careful temperature control, potential for lye exposure.

Hot Process:

- Advantages: Faster curing time (24-48 hours), easier to control consistency, allows for larger batches.

- Disadvantages: Requires specialized equipment, can result in a lower glycerin content.

Melt and Pour:

- Advantages: Most convenient method, no curing time, easy to create complex designs.

- Disadvantages: Limited customization, lower quality soap, contains synthetic ingredients.

5. How do you ensure the safety of your soap products and comply with industry regulations?

- Follow Good Manufacturing Practices (GMPs): Adhere to established standards for hygiene, equipment maintenance, and production processes.

- Use High-Quality Ingredients: Source oils, fats, and additives from reputable suppliers and ensure they meet safety standards.

- Proper Curing: Allow sufficient time for soap to cure and saponify fully, ensuring its safety and effectiveness.

- Testing and Analysis: Conduct pH testing and other quality control measures to verify the safety and performance of the soap.

- Comply with Regulations: Familiarize yourself with and comply with industry regulations and safety guidelines.

6. What are the common challenges faced in soap making and how do you overcome them?

- Lye Handling: Lye is a hazardous material that requires careful handling. Use proper safety gear and follow safety protocols to avoid accidents.

- Temperature Control: Maintaining proper temperatures during the saponification process is crucial. Use thermometers and monitor temperatures closely to ensure optimal results.

- Soap Troubleshooting: If the soap is too soft, hard, or doesn’t lather well, adjust the recipe or techniques accordingly.

- Scaling Up Production: Transitioning from small batches to larger-scale production requires careful planning and adjustments to ensure consistent quality.

7. Explain the importance of using high-quality ingredients in soap making and how it affects the final product

- Cleansing Ability: High-quality oils and fats provide better cleansing properties, resulting in a more effective soap.

- Lather and Foam: Certain oils, such as coconut oil, contribute to a rich and creamy lather.

- Skin Benefits: Oils like olive oil and shea butter have nourishing properties that can benefit the skin.

- Durability: Using high-quality ingredients helps the soap last longer and maintain its shape and properties over time.

8. What are the different types of essential oils and carrier oils used in soap making and their benefits?

Essential Oils

- Lavender: Calming and relaxing, promotes sleep.

- Tea Tree: Antibacterial and antifungal properties, suitable for acne-prone skin.

- Eucalyptus: Invigorating and decongesting, helps with respiratory issues.

Carrier Oils

- Coconut Oil: High in lauric acid, provides a rich lather and cleansing properties.

- Olive Oil: Moisturizing and nourishing, suitable for sensitive skin.

- Sweet Almond Oil: Rich in vitamins and minerals, helps soothe and soften the skin.

9. How do you incorporate exfoliants into soap and what are the benefits of using them?

- Types of Exfoliants: Natural exfoliants include oatmeal, sugar, salt, and coffee grounds.

- Benefits: Exfoliants help remove dead skin cells, improve circulation, and promote skin renewal.

- Incorporation: Exfoliants are added to the soap batter at the trace stage and mixed gently to avoid over-exfoliation.

10. Describe the different types of soap molds and how to choose the right one for your needs

- Silicone Molds: Flexible and easy to use, great for intricate designs and small batches.

- Wooden Molds: Durable and provide a rustic look, suitable for larger bars.

- Plastic Molds: Lightweight and inexpensive, but may not be as durable as other options.

- Consider factors such as: Soap size, design complexity, desired shape, and budget when selecting a mold.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soap Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soap Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Soap Makers are responsible for the production of various types of soaps, from simple bar soaps to complex liquid and specialty soaps. Their primary duties include:

1. Soap Production and Formulation

Following established recipes and production processes, Soap Makers are responsible for mixing and blending raw materials, including fats, oils, lye, and additives to create different soap formulations.

- Calculate and weigh ingredients accurately to ensure precise formulations.

- Operate soap-making equipment, such as mixers, boilers, and molds, to produce soaps.

2. Quality Control and Testing

Soap Makers are responsible for monitoring and maintaining the quality of the soap produced. They conduct various tests to ensure that the soaps meet specifications.

- Perform quality checks throughout the production process, including pH testing, moisture content analysis, and appearance inspection.

- Identify and rectify any quality issues, ensuring that only high-quality soaps are released for sale.

3. Sanitation and Safety

To maintain a clean and safe work environment, Soap Makers are responsible for adhering to industry regulations and company protocols.

- Follow established safety procedures and wear appropriate personal protective equipment (PPE) while handling chemicals and operating equipment.

- Maintain a clean and organized work area, ensuring proper storage and disposal of materials.

4. Inventory Management

Soap Makers are responsible for managing and maintaining the inventory of raw materials, packaging materials, and finished products.

- Maintain inventory records, ensuring timely replenishment of supplies.

- Monitor production schedules and adjust inventory levels accordingly.

Interview Tips

To prepare for an interview for a Soap Maker position, candidates can follow these tips:

1. Research the Company and Industry

Researching the company you are applying to and the soap-making industry will give you a deeper understanding of the role and the company’s values.

- Visit the company’s website to learn about their products, services, and company culture.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your skills and experience that are relevant to the job requirements.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Prepare examples of how you have successfully managed production processes, maintained quality standards, and ensured safety in previous roles.

3. Practice Soap Making Terminology

Familiarize yourself with common soap-making terminology, including ingredients, processes, and equipment.

- Review the basics of saponification, the chemical process that creates soap.

- Understand the different types of soap bases, such as lye-based, glycerin-based, and melt-and-pour.

4. Prepare for Technical Questions

Be prepared to answer technical questions about soap making, such as:

- “What is the difference between cold process and hot process soap making?”

- “How do you calculate the lye concentration for a specific soap recipe?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Soap Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.