Feeling lost in a sea of interview questions? Landed that dream interview for 3rd Pressman but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common 3rd Pressman interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

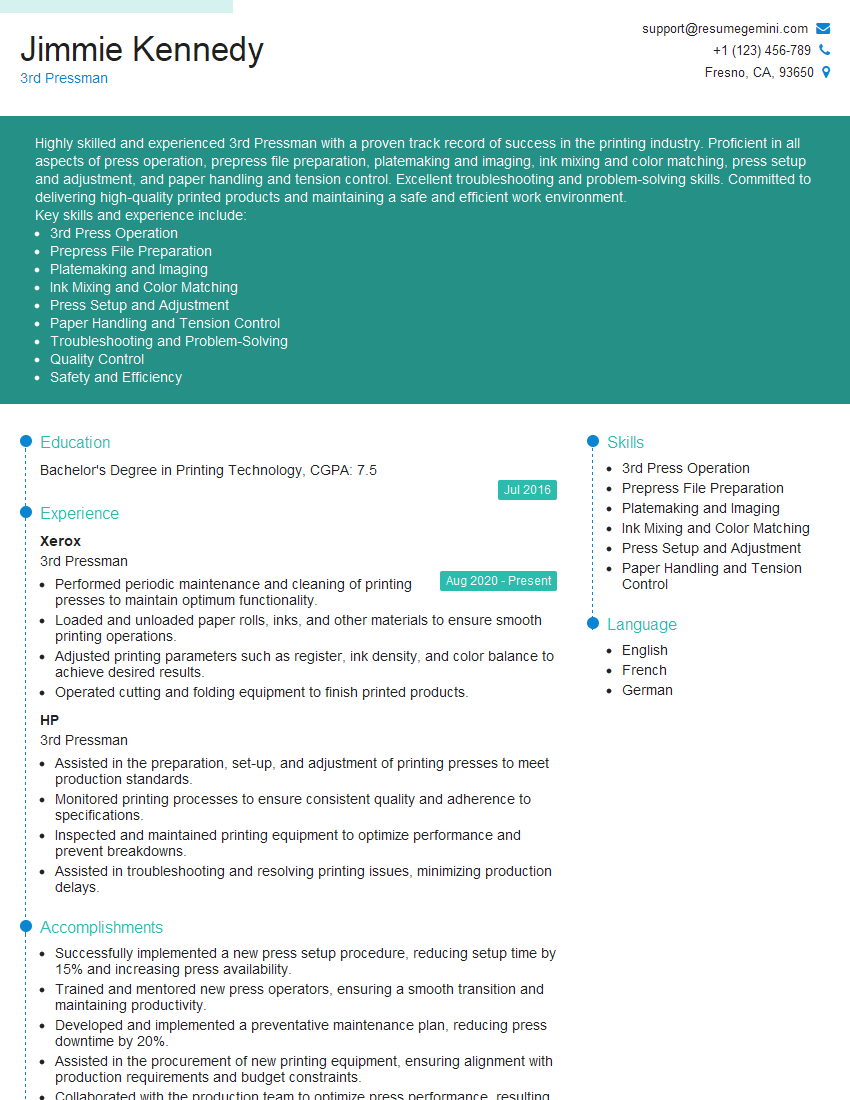

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For 3rd Pressman

1. Describe the process of makeready for a lithographic printing press.

The makeready process for a lithographic printing press involves several key steps:

- Plate mounting: The printing plate is mounted onto the press cylinder.

- Inking: The ink is applied to the plate using rollers.

- Dampening: The non-image areas of the plate are dampened with water to prevent ink from adhering to them.

- Impression: The paper is fed into the press and comes into contact with the plate. The ink from the plate transfers to the paper, creating the printed image.

- Delivery: The printed paper is delivered and stacked for further processing.

2. Explain the difference between offset printing and flexographic printing.

Offset printing

- Uses an inked metal plate that transfers the image to a rubber roller, which then transfers the image to the paper.

- Produces high-quality images with fine details and accurate color reproduction.

- Suitable for a wide range of substrates, including paper, cardboard, and metal.

Flexographic printing

- Uses a flexible rubber or polymer plate that directly transfers the ink to the substrate.

- Produces consistent and durable prints on non-porous substrates, such as plastic, film, and packaging materials.

- Suitable for high-volume printing applications, such as packaging and labeling.

3. What are the different types of printing inks and their applications?

There are several types of printing inks, each with its own unique properties and applications:

- Oil-based inks: Used in offset printing and flexographic printing, offer good adhesion, durability, and resistance to fading.

- Water-based inks: Used in offset printing and flexographic printing, contain water as the main solvent, environmentally friendly, and suitable for printing on absorbent substrates.

- UV-curable inks: Used in offset printing and flexographic printing, cured by exposure to ultraviolet light, providing high gloss, scratch resistance, and fast drying time.

- Solvent-based inks: Used in gravure printing and flexographic printing, offer high pigment load and fast drying time, suitable for packaging and industrial applications.

4. Describe the operation and maintenance of a web offset printing press.

A web offset printing press operates by feeding a continuous roll of paper (web) through the press, where it is printed and then cut into individual sheets:

- The web is fed into the press and passes through a series of rollers.

- The plate cylinders transfer the ink to the paper.

- The paper is then cut into individual sheets.

- Regular maintenance is crucial, including cleaning, lubrication, and adjustments to ensure optimal press performance and print quality.

5. Explain the principles of color separation and the use of CMYK inks in printing.

Color separation involves separating an image into its component colors (cyan, magenta, yellow, and black) to create printing plates:

- Each plate is inked with the corresponding color and transferred to the paper in sequence.

- When combined, these colors create a full-color image.

- Black ink (K) is added to enhance contrast and depth.

6. Describe the different types of paper used in printing and their properties.

There are various types of paper used in printing, each with its own unique characteristics:

- Coated paper: Has a smooth, glossy surface, suitable for high-quality printing and vibrant colors.

- Uncoated paper: Has a more natural, matte finish, suitable for writing, drawing, and everyday printing.

- Recycled paper: Made from recycled materials, environmentally friendly, and suitable for various applications.

- Specialty paper: Includes textured, metallic, and fluorescent papers, used for unique and decorative effects.

7. Explain the process of calibrating and maintaining color accuracy in printing.

Color calibration is crucial to ensure consistent and accurate color reproduction:

- Color profiles are created to define the color characteristics of the printing system.

- Calibration involves adjusting the press and inks to match these profiles.

- Regular maintenance, including cleaning and monitoring, is necessary to maintain color accuracy over time.

8. Describe the different types of printing defects and how to troubleshoot them.

Common printing defects include:

- Ink smudging: Caused by excessive ink or improper paper handling.

- Ghosting: Caused by a double impression due to misregistration or plate damage.

- Tinting: Caused by uneven ink distribution or insufficient dampening.

- Uneven density: Caused by variations in ink flow or plate exposure.

Troubleshooting involves identifying the root cause and implementing corrective measures, such as adjusting press settings, cleaning components, or replacing defective parts.

9. Explain the principles of digital printing and its advantages over traditional printing methods.

Digital printing uses digital files to directly print images onto a variety of substrates:

- Eliminates the need for printing plates, reducing setup time and cost.

- Allows for variable data printing, such as personalized mailings.

- Offers faster turnaround times and flexibility for short-run printing.

10. Describe the safety precautions and regulations that must be followed in a printing press environment.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when servicing equipment.

- Handle chemicals and inks safely, including proper storage and disposal.

- Maintain a clean and organized work area.

- Be aware of potential hazards, such as moving machinery and electrical equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for 3rd Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the 3rd Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The 3rd Pressman plays a crucial role in the smooth operation of the printing press, ensuring the delivery of high-quality printed products. Their key responsibilities include:

1. Preparing and Operating Printing Press

Sets up and prepares the printing press according to job specifications, ensuring proper alignment and registration of materials.

- Adjusts ink flow, pressure, and speed to achieve optimal print quality.

- Monitors press performance and makes necessary adjustments to maintain production efficiency.

2. Loading and Unloading Paper

Loads and unloads paper stock into the press and ensures proper alignment and tension.

- Inspect paper for defects and removes any damaged or misaligned sheets.

- Adjusts paper feed and delivery systems to prevent paper jams and other issues.

3. Quality Control

Inspects printed materials for defects, such as smudging, misalignment, or color variations.

- Identifies and corrects printing errors promptly to maintain product quality.

- Maintains records of press performance and quality control measures.

4. Machine Maintenance

Performs basic maintenance and troubleshooting on printing equipment, including cleaning, lubrication, and minor repairs.

- Reports any major issues or equipment malfunctions to supervisors.

- Assists with preventative maintenance and equipment upgrades.

Interview Tips

To ace the interview for a 3rd Pressman position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the printing company’s products, services, and industry reputation.

- Research the specific printing technologies and equipment used by the company.

- Read industry publications and attend trade shows to stay up-to-date on printing trends.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating printing presses and your understanding of printing principles.

- Provide examples of your ability to troubleshoot and resolve printing issues.

- Showcase your knowledge of different paper types, inks, and printing techniques.

3. Demonstrate Your Attention to Detail

Stress your meticulous nature and ability to produce high-quality printed materials.

- Explain how you maintain proper press settings and monitor print quality throughout the production process.

- Share your experience in identifying and correcting printing errors.

4. Be a Team Player

Printing often involves collaboration, so emphasize your ability to work effectively in a team environment.

- Discuss your experience in coordinating with other press operators, supervisors, and customers.

- Highlight your willingness to share knowledge and assist others.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the position and the company.

- Inquire about the company’s growth plans and the role of the 3rd Pressman in those plans.

- Ask about the company’s commitment to quality control and customer satisfaction.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the 3rd Pressman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!