Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Abrasive Coating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

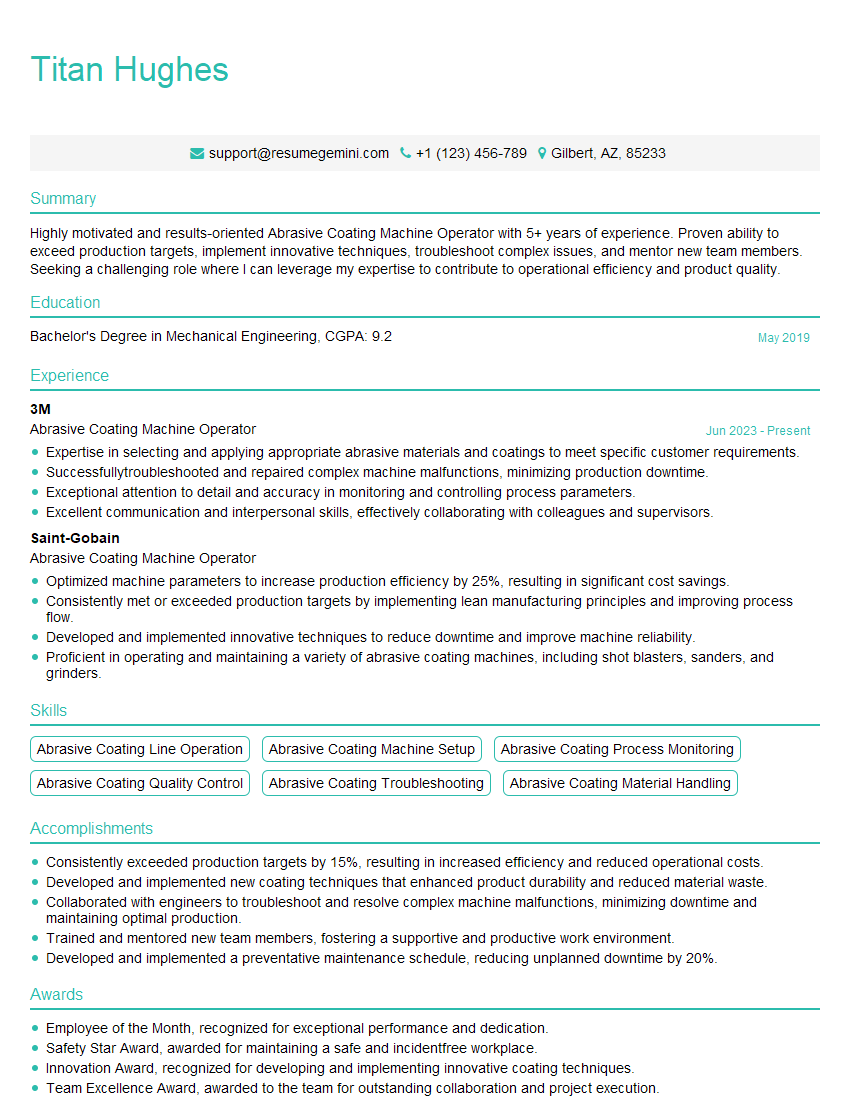

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Coating Machine Operator

1. What are the key responsibilities of an Abrasive Coating Machine Operator?

- Operate, monitor, and adjust abrasive coating machines to apply coatings on various surfaces.

- Inspect the production line to ensure the smooth operation of the machine.

- Ensuring the high quality of coated products by monitoring and controlling the coating process.

2. Describe the process of abrasive coating and its different applications?

Variables of coating parameters

- Abrasive material types and their properties

- Coating thickness and uniformity

- Production speed and efficiency

Different applications of abrasive coating

- Surface preparation for painting, welding, or bonding

- Deburring and finishing of metal components

- Surface texturing for improved grip or wear resistance

3. What are the different types of abrasive coatings available and their properties?

- Ceramic abrasives: Hard and durable, suitable for heavy-duty applications.

- Aluminum oxide abrasives: Medium hardness, cost-effective, and widely used.

- Silicon carbide abrasives: Sharp and fast-cutting, suitable for precision grinding.

- Zirconia abrasives: Durable and heat-resistant, suitable for high-temperature applications.

4. How do you ensure the quality of abrasive coatings and identify potential defects?

- Visual inspection for even coating thickness, surface finish, and adhesion.

- Microscopic examination to verify coating properties, such as crystal structure and porosity.

- Mechanical testing to assess hardness, wear resistance, and bond strength.

- Non-destructive testing methods, such as ultrasonic or magnetic particle inspection, to detect hidden defects.

5. Describe the safety protocols and maintenance procedures for abrasive coating machines?

Safety protocols

- Wearing appropriate safety gear, including gloves, eye protection, and respirators.

- Ensuring proper ventilation to prevent dust inhalation.

- Following lockout/tagout procedures before performing maintenance.

Maintenance procedures

- Regularly cleaning and lubricating the machine to prevent wear and tear.

- Inspecting and replacing worn or damaged parts to ensure optimal performance.

- Calibrating the machine to maintain accurate coating parameters.

6. What are the principles of abrasive coating thickness measurement, and what techniques are used?

Principles of abrasive coating thickness measurement

- Measuring the change in electrical resistance due to the coating layer.

- Determining the magnetic field strength affected by the coating layer.

- Using optical microscopy to measure the cross-section of the coating.

Techniques used for abrasive coating thickness measurement

- Eddy current testing

- Magnetic flux leakage

- Confocal microscopy

7. How do you troubleshoot common issues that may arise during the abrasive coating process?

- Identifying the root cause of the problem through process analysis.

- Inspecting the machine components, such as the coating head, conveyor, and sensors.

- Adjusting coating parameters, such as speed, pressure, and temperature.

- Cleaning or replacing contaminated or worn parts.

8. What are the advancements in abrasive coating technology, and how do they impact your work?

- Development of new abrasive materials with improved hardness and durability.

- Implementation of advanced control systems for precise coating application.

- Integration of sensors and automation for real-time monitoring and process optimization.

9. How do you stay updated with the latest industry standards and best practices related to abrasive coating?

- Attending industry conferences and workshops.

- Reading technical journals and articles on abrasive coating.

- Consulting with experts in the field.

10. How do you handle working in a fast-paced and demanding environment?

- Prioritizing tasks and managing time effectively.

- Communicating clearly and collaborating with team members.

- Staying focused and maintaining accuracy even under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Coating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Coating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Abrasive Coating Machine Operator performs a variety of tasks relating to the operation, maintenance, and safety of abrasive coating machines. They are the main enforcer of safety standards in the workplace and follow proper safety procedures to ensure the safety and quality of the product. They are also responsible for monitoring the performance of the machine and quality of the coating, as well as performing basic machine maintenance.

1. Operation of Coating Machine

Monitors the operation of the abrasive coating machine to ensure that the coating is uniformly and correctly applied to the specified thickness and other specifications.

- Operates controls that regulate the speed and thickness of coating, and adjusts them as necessary to maintain consistent quality.

- Observes and controls the flow of material to ensure that the coating is applied evenly and without defects.

2. Maintenance and Inspection

Performs basic maintenance procedures on the coating machine to ensure that it is running smoothly and efficiently.

- Lubricates moving parts, cleans the machine and checks for any wear or damage.

- Reports any problems or malfunctions to the supervisor and assists with repairs as needed.

3. Quality Assurance

Inspects the coated products to ensure that they meet specifications and quality standards and maintains quality records.

- Conducts tests or measurements to ensure that the coating meets the required specifications.

- Identifies and corrects any defects in the coating process or finished product.

4. Safety and Environmental Compliance

Complies with all safety regulations and environmental standards relating to the operation of abrasive coating machines.

- Ensures the machine is properly grounded and guarded to prevent accidents.

- Uses personal protective equipment and follows proper waste disposal procedures.

Interview Preparation Tips

Preparing for an interview for an Abrasive Coating Machine Operator position can help you make a strong impression and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the Company and Position

Before the interview, take some time to thoroughly research the company and the specific Abrasive Coating Machine Operator position.

- Visit the company’s website and read about their mission, values, and products or services.

- Read the job description carefully and identify the key requirements and qualifications.

- Identify the skills and experiences that you have that are most relevant to the position.

2. Practice Answering Common Interview Questions

Some common interview questions that you may be asked include:

- “Tell me about your experience operating abrasive coating machines.”

- “How do you ensure the quality of your work?”

- “What are some of the safety regulations that you follow when operating an abrasive coating machine?”

Prepare responses to these and other common interview questions by highlighting your skills, experience, and qualifications. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you are engaged and interested in the position. Questions can range from the company culture, career advancement opportunities, training programs and safety standards.

- “What are the company’s goals for the next year?”

- “What are the opportunities for professional development and advancement within the company?”

- “What is the company’s safety record and what measures are in place to ensure a safe working environment?”

4. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for your interview.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive for your interview at least 10 minutes early to give yourself time to check in and compose yourself.

5. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude.

- Smile, make eye contact, and speak clearly.

- Show the interviewer that you are genuinely interested in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Abrasive Coating Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!