Are you gearing up for a career in Abrasive Grader Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Abrasive Grader Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

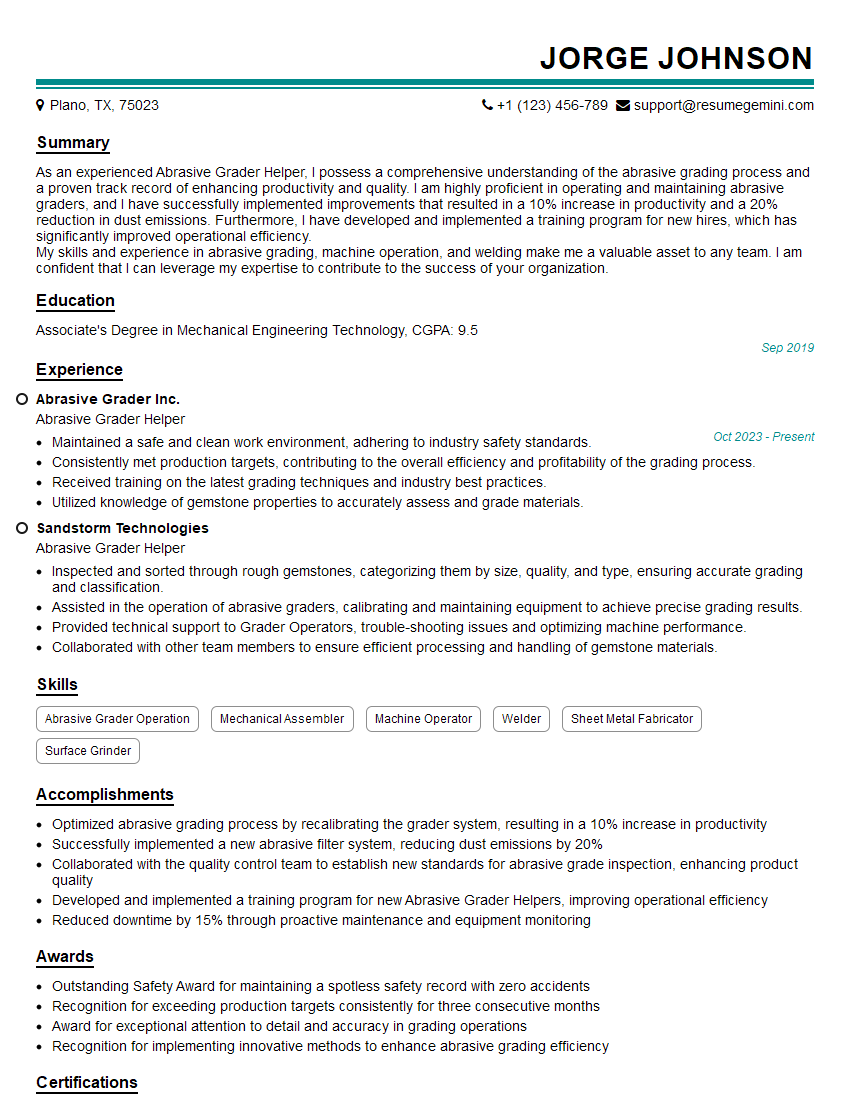

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Grader Helper

1. Explain the process of abrasive grading?

Abrasive grading is a process of sorting and classifying abrasive particles based on their size and shape. It’s a crucial step in the manufacturing of abrasives, as the size and shape of the particles determine the abrasive’s performance and applications.

- The process typically involves using a series of screens or sieves with different mesh sizes.

- The abrasive particles are passed through these screens, and the particles that pass through a particular screen are collected and classified according to the mesh size of the screen.

- This process is repeated until the abrasive particles are sorted into the desired size and shape ranges.

2. What are the different types of abrasive grading equipment?

There are various types of abrasive grading equipment used in the industry, each with its own advantages and applications.

Mechanical sieving

- Mechanical sieving is a traditional method that uses a series of screens or sieves with different mesh sizes.

- The abrasive particles are passed through these screens, and the particles that pass through a particular screen are collected and classified according to the mesh size of the screen.

Air classification

- Air classification utilizes a stream of air to separate abrasive particles based on their size and density.

- The abrasive particles are introduced into an air stream, and the lighter particles are carried away by the air while the heavier particles fall into a collection bin.

Elutriation

- Elutriation is a process that uses a rising column of water or air to separate abrasive particles based on their size and density.

- The abrasive particles are introduced into the rising column, and the smaller particles are carried away by the fluid while the larger particles settle to the bottom of the column.

Sonic sifting

- Sonic sifting utilizes ultrasonic waves to separate abrasive particles based on their size and shape.

- The abrasive particles are placed on a screen, and ultrasonic waves are applied to the screen.

- The ultrasonic waves create vibrations that cause the smaller particles to pass through the screen while the larger particles remain on the screen.

3. How do you ensure the accuracy and consistency of abrasive grading?

Ensuring the accuracy and consistency of abrasive grading is crucial to maintain the quality and performance of the abrasives.

- Regularly calibrate and maintain the grading equipment to ensure it’s operating within the desired specifications.

- Use standardized testing methods and procedures to ensure consistency in the grading process.

- Implement quality control measures, such as sampling and testing, to verify the accuracy and consistency of the grading results.

4. What are the common challenges encountered in abrasive grading and how do you overcome them?

Abrasive grading can present certain challenges that need to be addressed to ensure efficient and effective operations.

- Contamination: Abrasive particles can become contaminated with other materials, such as dust or debris, which can affect their grading and performance.

- Moisture: Moisture can cause abrasive particles to clump together, making it difficult to separate them during grading.

- Equipment limitations: The accuracy and efficiency of abrasive grading can be limited by the capabilities of the grading equipment.

To overcome these challenges, it’s important to:

- Implement proper storage and handling practices to minimize contamination.

- Control moisture levels in the grading environment to prevent clumping.

- Regularly maintain and calibrate grading equipment to ensure optimal performance.

5. How do you stay updated with the latest advancements in abrasive grading technology?

The abrasive grading industry is constantly evolving, with new technologies and techniques emerging regularly.

- Attend industry conferences and exhibitions: These events provide a platform to learn about the latest advancements and connect with experts in the field.

- Read industry publications and technical journals: Stay informed about the latest research and developments in abrasive grading.

- Network with other professionals: Engage with colleagues, suppliers, and equipment manufacturers to exchange knowledge and insights.

6. Can you describe a situation where you successfully resolved a problem related to abrasive grading?

In my previous role, we encountered an issue where the abrasive grading process was resulting in inconsistent particle sizes.

- Identified the problem: I conducted a thorough investigation and identified that the problem was caused by a faulty screen in the grading equipment.

- Developed a solution: I replaced the faulty screen with a new one that met the required specifications.

- Verified the solution: I conducted a series of tests to verify that the grading process was now producing consistent particle sizes.

7. What are the safety precautions that should be taken when working with abrasive materials?

Working with abrasive materials requires strict adherence to safety precautions to prevent injuries and health hazards.

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and a respirator to protect against dust and particles.

- Handle abrasive materials carefully: Avoid direct contact with abrasive particles and always use proper tools and equipment.

- Maintain a clean and well-ventilated work area: Dust and particles can accumulate, creating a potential respiratory hazard.

8. How do you maintain and troubleshoot abrasive grading equipment?

Regular maintenance and troubleshooting are crucial to ensure the optimal performance of abrasive grading equipment.

- Regular maintenance: Follow the manufacturer’s recommended maintenance schedule, including cleaning, lubrication, and replacement of worn parts.

- Troubleshooting: If the equipment malfunctions, follow a systematic troubleshooting process to identify and resolve the issue.

- Calibration: Regularly calibrate the equipment to ensure accurate grading results.

9. What is the role of quality control in abrasive grading?

Quality control plays a vital role in abrasive grading, ensuring that the abrasives meet the required specifications and standards.

- Establish quality standards: Define clear and measurable quality standards for the abrasive products.

- Implement testing and inspection procedures: Conduct regular testing and inspections to verify that the abrasives meet the established standards.

- Monitor and analyze data: Collect and analyze data from testing and inspections to identify trends and areas for improvement.

10. How do you manage and optimize the abrasive grading process to improve efficiency and productivity?

Optimizing the abrasive grading process requires a combination of strategies and techniques.

- Process mapping: Map out the grading process to identify bottlenecks and areas for improvement.

- Automation: Explore opportunities to automate certain tasks, such as material handling and data collection, to increase efficiency.

- Lean manufacturing principles: Implement lean manufacturing principles to reduce waste and improve overall productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Grader Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Grader Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Abrasive Grader Helpers are essential in maintaining the grinding and grading process in a variety of industries. They work closely with Abrasive Grader Operators to ensure the smooth functioning of the production line.

1. Abrasive Handling

Abrasive Grader Helpers are responsible for handling abrasive materials, such as garnet, aluminum oxide, and silicon carbide. They may need to load and unload these materials into hoppers, bins, or other containers.

2. Machine Operation

Abrasive Grader Helpers may assist in operating abrasive grading machines. They may need to adjust settings, monitor the flow of materials, and make sure that the machines are running properly.

3. Maintenance and Cleaning

Maintaining a clean and safe work environment is an important responsibility for Abrasive Grader Helpers. They may need to clean equipment, sweep floors, and dispose of waste materials.

4. Quality Control

Abrasive Grader Helpers may be involved in quality control processes. They may need to inspect materials, check for defects, and ensure that the final product meets specifications.

Interview Tips

Preparing thoroughly for an Abrasive Grader Helper interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Researching the company and the specific position you’re applying for demonstrates your interest and enthusiasm. Visit the company website, check out their social media pages, and read any news articles or industry reports about them. This will give you a good understanding of the company’s culture, values, and goals.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the actual interview. Some common questions you may encounter include:

- Tell me about your experience working with abrasive materials.

- What are your strengths and weaknesses as an Abrasive Grader Helper?

- Why are you interested in this position?

You can find additional interview questions and practice tips online or in career counseling books.

3. Highlight Your Relevant Skills and Experience

During the interview, highlight your skills and experience that are relevant to the job. For example, if you have experience operating abrasive grading machines, be sure to mention this in detail. You can also share any knowledge you have about abrasive materials, quality control, or safety procedures.

4. Be Enthusiastic and Professional

Be enthusiastic and professional throughout the interview. This will show the interviewer that you’re interested in the position and that you’re a hard worker. Dress appropriately, arrive on time, and be polite to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Abrasive Grader Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!