Feeling lost in a sea of interview questions? Landed that dream interview for Abrasive Grader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Abrasive Grader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

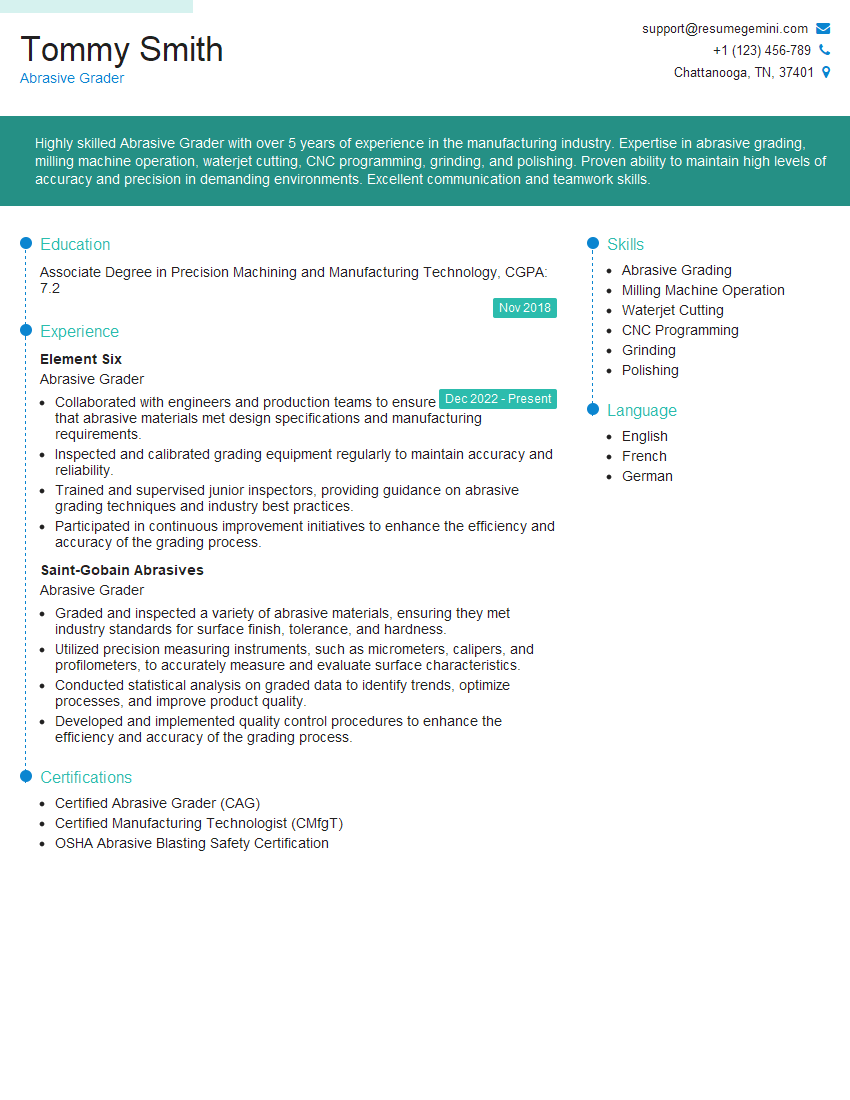

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Grader

1. How would you set up and calibrate an abrasive grader?

– Prepare the machine: Ensure the machine is level and secure. – Install the abrasive wheel: Mount the wheel securely and adjust the angle as per the manufacturer’s specifications. – Adjust the feed rate: Set the feed rate to the desired value based on the material being graded. – Calibrate the machine: Use a calibration block or other reference surface to calibrate the grader’s depth of cut.

2. What are the different types of abrasive wheels used in abrasive grading?

Ceramic wheels

- High hardness and wear resistance

- Suitable for grinding hard materials such as metal and ceramics

Diamond wheels

- Exceptional hardness and durability

- Used for precision grinding and cutting of hard materials like glass and stone

CBN wheels

- High hardness and thermal stability

- Suitable for grinding hardened steel and other high-alloy materials

3. Describe the process of surface grinding using an abrasive grader.

– Mount the workpiece: Secure the workpiece on the machine table. – Adjust the machine: Set the wheel speed, feed rate, and depth of cut. – Start the grinding: Lower the wheel onto the workpiece and initiate the grinding process. – Monitor the process: Observe the grinding progress and make adjustments as necessary to achieve the desired finish. – Inspect the surface: Verify the accuracy and quality of the surface using appropriate measuring tools.

4. How do you determine the optimal grinding conditions for a specific material?

– Consider material properties: Hardness, toughness, and grain size influence the grinding parameters. – Experiment with different wheels: Test various wheel types, grits, and grades to find the most suitable combination. – Analyze grinding results: Examine the surface finish, grinding force, and cycle time to optimize conditions. – Consult industry standards and manufacturer recommendations: Refer to established guidelines for appropriate grinding parameters.

5. What safety precautions should be observed when operating an abrasive grader?

- Wear appropriate personal protective equipment (PPE), including eye protection, gloves, and a respirator.

- Securely fasten the workpiece to prevent any loose parts from flying.

- Inspect the machine regularly for any defects or damage.

- Handle the abrasive wheel with care, avoiding any impacts or accidental damage.

- Follow all operating instructions and manufacturer’s guidelines.

6. Describe the different types of surface finishes that can be achieved with abrasive grading.

- Rough surface:** Coarse abrasives create a rough surface with high surface area.

- Smooth surface:** Medium-grit abrasives produce a smooth surface with reduced friction.

- Ultra-smooth surface:** Fine-grit abrasives generate an ultra-smooth surface with minimal surface imperfections.

7. What factors affect the accuracy of abrasive grading?

- Machine precision:

- Accuracy of table movement

- Precision of wheel spindle

- Wheel condition:

- Sharpness of abrasive grains

- Wheel balance

- Workpiece properties:

- Material hardness

- Workpiece geometry

- Environmental factors:

- Temperature

- Humidity

8. How do you troubleshoot common problems encountered during abrasive grading?

- Excessive wheel wear:

- Check wheel condition and replace if worn

- Adjust grinding parameters (e.g., feed rate, depth of cut)

- Poor surface finish:

- Select a more suitable abrasive wheel (grit, grade)

- Optimize grinding conditions (e.g., speed, feed)

- Machine vibration:

- Check machine balance and alignment

- Reduce grinding forces (e.g., adjust feed rate, depth of cut)

9. What are the maintenance procedures for an abrasive grader?

- Regular cleaning:

- Remove dust and debris from the machine

- Clean and lubricate moving parts

- Wheel dressing:

- Restore wheel shape and sharpness

- Use a dressing stick or diamond dresser

- Spindle lubrication:

- Ensure proper lubrication of the wheel spindle

- Follow manufacturer’s guidelines for lubrication frequency

10. How do you ensure the quality of abrasive grading operations?

- Establish quality standards:

- Define acceptable surface finish, dimensional accuracy, etc.

- Document quality specifications for each part or batch

- Implement quality control measures:

- Monitor grinding process parameters

- Inspect finished parts using measuring tools and gauges

- Continuous improvement:

- Analyze quality data to identify areas for improvement

- Implement process enhancements to optimize performance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Abrasive Graders are responsible for overseeing the grading process of abrasive materials, such as sand, gravel, and crushed rock. They ensure that the materials meet specific quality standards and specifications.

1. Material Inspection and Analysis

Inspect incoming abrasive materials for quality and compliance with specifications.

- Conduct visual inspections to identify physical characteristics and impurities.

- Perform laboratory tests to determine particle size distribution, hardness, and other properties.

2. Grading and Sorting

Operate grading equipment to separate abrasive materials into different sizes and grades.

- Calibrate and maintain grading screens, crushers, and other machinery.

- Monitor the grading process to ensure accurate particle size distribution.

3. Quality Control and Assurance

Adhere to established quality standards and specifications for abrasive materials.

- Conduct regular inspections to ensure materials meet customer requirements.

- Provide feedback to suppliers and production teams to improve the grading process.

4. Equipment Maintenance and Repair

Perform routine maintenance and repairs on grading equipment.

- Clean, lubricate, and adjust equipment to ensure optimal performance.

- Troubleshoot and resolve mechanical or electrical issues.

5. Safety and Compliance

Maintain a safe and compliant work environment.

- Follow established health and safety regulations.

- Operate equipment according to manufacturer’s instructions.

Interview Tips

Preparing thoroughly for an Abrasive Grader interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Demonstrate your interest in the company and the role by researching their website, industry news, and recent developments.

- Identify the company’s mission, values, and key products/services.

- Understand the specific responsibilities and requirements of the Abrasive Grader role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments whenever possible.

- Showcase your expertise in material inspection, grading, and quality control.

- Highlight your experience operating and maintaining grading equipment.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Consider the following questions:

- “Tell me about your experience in grading abrasive materials.”

- “How do you ensure the quality of graded materials meets customer specifications?”

- “Describe a situation where you had to troubleshoot and resolve an issue with grading equipment.”

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role.

- Inquire about the company’s growth plans and industry trends.

- Ask about the team structure and opportunities for professional development.

5. Follow Up Professionally

After the interview, follow up with a thank-you note to the interviewer. Express your appreciation and reiterate your interest in the role.

- Refer to specific aspects of the interview or the company that made a positive impression.

- Provide any additional information or clarification that might strengthen your application.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Abrasive Grader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Abrasive Grader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.