Are you gearing up for a career in Abrasive Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Abrasive Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

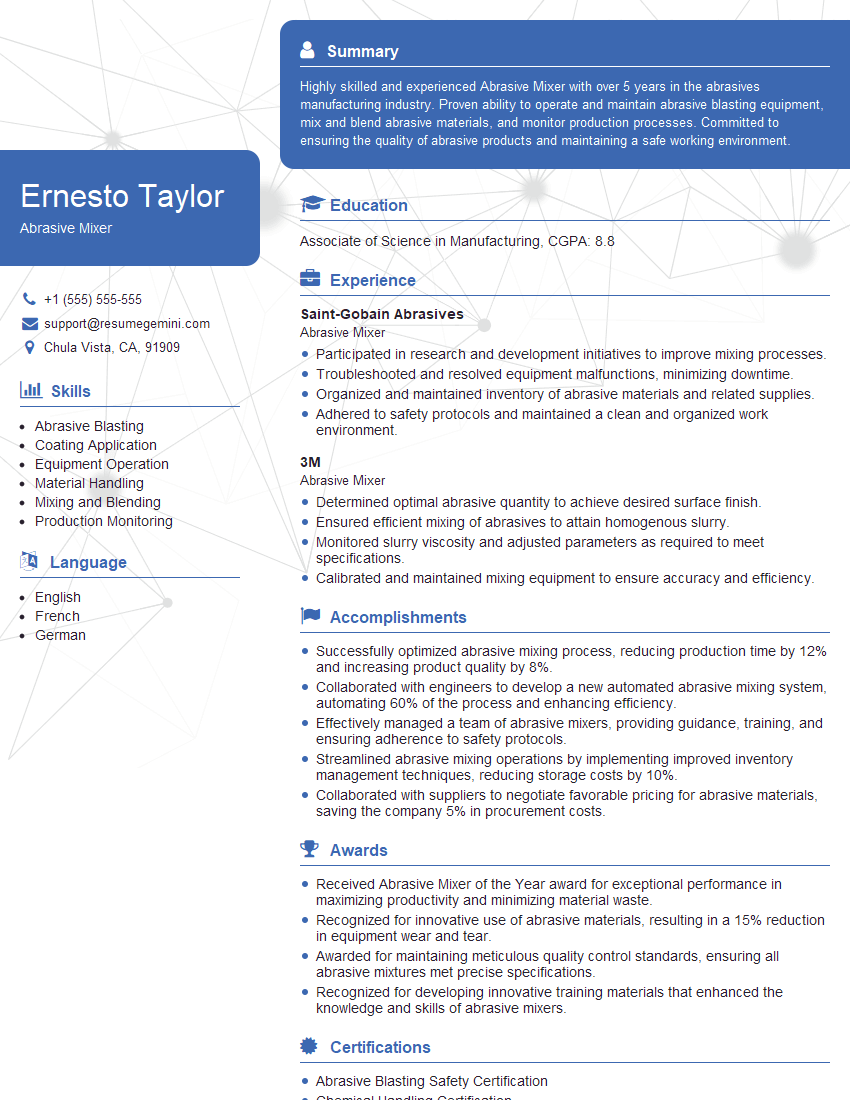

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Mixer

1. Describe the key responsibilities of an Abrasive Mixer.

- Measure and mix abrasive materials according to predetermined formulas.

- Monitor and control the mixing process to ensure the desired consistency and quality of the mixture.

- Operate and maintain mixing equipment, such as blenders, mixers, and conveyors.

- Clean and maintain the mixing area to maintain a safe and efficient work environment.

- Collaborate with production staff and other team members to ensure the timely delivery of quality abrasive mixtures.

2. Explain the different methods and techniques used in abrasive mixing.

Wet Mixing

- Abrasive particles are mixed with water to form a slurry.

- Provides better control over particle distribution and consistency.

Dry Mixing

- Abrasive particles are mixed without the addition of water.

- Faster and more energy-efficient process.

Vacuum Mixing

- Abrasive particles are mixed under vacuum conditions to remove air and moisture.

- Produces high-quality mixtures with improved durability and performance.

3. How do you ensure the accuracy and consistency of abrasive mixtures?

- Follow standardized mixing procedures and formulas.

- Use calibrated measuring equipment and scales.

- Monitor the mixing process and make necessary adjustments based on visual inspection and testing.

- Document mixing parameters and keep records for traceability.

- Collaborate with quality control personnel to verify the quality of the mixtures.

4. What troubleshooting techniques do you employ when encountering problems with the mixing process?

- Identify the source of the problem by analyzing the symptoms and observing the mixing process.

- Check equipment functionality and calibrate if necessary.

- Adjust mixing parameters, such as mixing time and agitation speed.

- Contact technical support or consult with experienced colleagues.

- Document the issue and the corrective actions taken for future reference.

5. How do you handle and store abrasive materials safely?

- Wear appropriate personal protective equipment (PPE), such as gloves, masks, and eye protection.

- Follow proper handling procedures to prevent spills and exposure to dust and fumes.

- Store abrasive materials in dry, well-ventilated areas away from incompatible substances.

- Dispose of hazardous waste in accordance with environmental regulations.

- Maintain a clean and organized work area to minimize risks.

6. What is the role of quality control in abrasive mixing?

- Establishes and maintains quality standards for abrasive mixtures.

- Conducts inspections and tests to ensure that mixtures meet specifications.

- Identifies non-conforming mixtures and takes corrective actions.

- Provides feedback to the mixing team on areas for improvement.

- Contributes to the overall quality management system of the organization.

7. Describe the different types of mixing equipment used in abrasive mixing.

- Batch Mixers: Mix small batches of abrasive materials in a closed container.

- Continuous Mixers: Mix large volumes of abrasive materials in a continuous process.

- Paddle Mixers: Use rotating paddles to mix abrasive materials.

- Ribbon Mixers: Use helical ribbons to mix abrasive materials gently and efficiently.

- Tumble Blenders: Rotate the mixing container to mix abrasive materials by tumbling.

8. How do you calculate the mixing ratios for abrasive mixtures?

9. What factors can affect the quality of abrasive mixtures?

- Quality of the abrasive materials used.

- Accuracy of the mixing ratios.

- Effectiveness of the mixing process.

- Consistency of the mixing environment (temperature, humidity).

- Equipment maintenance and calibration.

10. How do you stay up-to-date with the latest advancements in abrasive mixing technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other professionals in the field.

- Seek opportunities for training and professional development.

- Collaborate with equipment manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Abrasive Mixer plays a vital role in the manufacturing of abrasives, materials used in grinding, cutting, and polishing. Their key responsibilities include:

1. Blending and Mixing Abrasives

Abrasive Mixers are responsible for blending and mixing various types of abrasives, such as aluminum oxide, silicon carbide, and garnet, according to specified formulations.

- Operate mixing equipment to combine different grades and types of abrasives.

- Ensure proper proportions and consistency of blended materials.

2. Controlling Mixing Process

They monitor and control the mixing process to achieve the desired properties of the abrasive mixtures.

- Adjust mixing parameters, such as speed, temperature, and duration, to optimize blend quality.

- Monitor equipment performance and make necessary adjustments to maintain efficiency and quality.

3. Quality Control

Abrasive Mixers conduct quality control checks to ensure that the blended abrasives meet the required specifications.

- Perform physical and chemical tests on abrasive samples to verify their properties.

- Maintain records of quality control data for traceability and compliance purposes.

4. Equipment Maintenance

They are responsible for maintaining and cleaning mixing equipment to ensure optimal performance.

- Inspect and clean mixing machines, tanks, and other equipment.

- Perform minor repairs and report any major issues to supervisors.

Interview Tips

To ace an interview for an Abrasive Mixer position, candidates should prepare by understanding the key job responsibilities and highlighting their relevant skills and experience.

1. Research the Industry and Company

Familiarize yourself with the abrasive manufacturing industry and the specific company you’re applying to. This shows your interest and enthusiasm for the role.

- Visit the company’s website to learn about their products, processes, and values.

- Read industry publications and articles to stay informed about the latest trends and technologies.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to the key job responsibilities mentioned above, such as:

- “Tell me about your experience in blending and mixing abrasives.” Give specific examples of your work.

- “How do you ensure the quality of blended abrasives?” Explain your approach to quality control.

- “What is your experience with maintaining mixing equipment?” Describe your responsibilities and any relevant training.

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the role. These may include:

- Strong understanding of abrasive materials and their properties.

- Experience in operating and maintaining mixing equipment.

- Excellent attention to detail and commitment to quality.

- Ability to work independently and as part of a team.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Consider asking about:

- “Can you describe the company’s quality control procedures for abrasive mixtures?”

- “What are the opportunities for professional development within the company?”

- “What is the company’s commitment to environmental sustainability in its manufacturing processes?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Abrasive Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.