Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Abrasive Sawyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

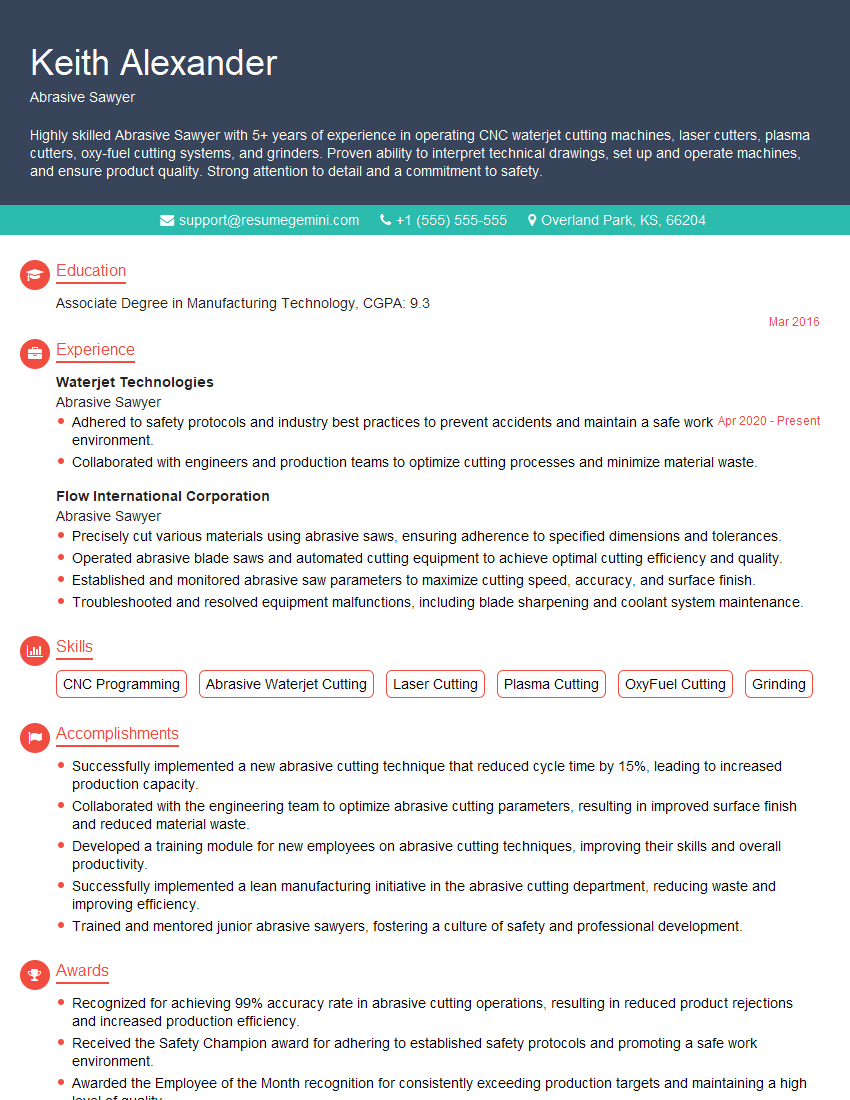

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Sawyer

1. What are the different types of abrasive saws?

- Chop saws

- Cold saws

- Circular saws

- Panel saws

- Band saws

2. What are the key factors to consider when selecting an abrasive saw blade?

Material to be cut

- Different materials require different types of blades

Blade size

- The blade size must be compatible with the saw

Blade type

- There are different types of blades available, each with its own advantages and disadvantages

3. How do you maintain an abrasive saw?

- Regularly clean the saw and remove any debris

- Lubricate the saw according to the manufacturer’s instructions

- Inspect the saw for any damage and repair or replace parts as needed

4. What safety precautions should be taken when using an abrasive saw?

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves

- Secure the material to be cut before starting the saw

- Never reach over the saw blade while it is running

- Unplug the saw before making any adjustments or repairs

5. What are the advantages of using an abrasive saw?

- Can cut a wide variety of materials

- Precise cuts

- Efficient cutting

6. What are the disadvantages of using an abrasive saw?

- Can be noisy

- Can create dust

- Can be dangerous if not used properly

7. What are the different types of abrasives used in abrasive saws?

- Aluminum oxide

- Silicon carbide

- Ceramic

- Diamond

- Cubic boron nitride

8. How do you choose the right abrasive for a particular application?

- Consider the material to be cut

- Consider the desired surface finish

- Consider the cost of the abrasive

9. How do you troubleshoot common problems with abrasive saws?

- The saw is not cutting properly

- The saw is making excessive noise

- The saw is vibrating excessively

10. What are the latest trends in abrasive saw technology?

- Laser-guided saws

- Automated saws

- High-speed saws

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of an Abrasive Sawyer

An Abrasive Sawyer is responsible for operating and maintaining abrasive sawing machines to cut and shape various materials. This role involves handling abrasive wheels, setting up and adjusting machines, and ensuring the safe and efficient operation of the equipment.

1. Machine Operation and Maintenance

• Operate abrasive sawing machines to cut and shape materials according to specifications.

- Select and install appropriate abrasive wheels based on material type and desired cut.

- Adjust machine settings for optimal cutting speed, feed rate, and depth.

- Inspect and maintain machines regularly to ensure proper functioning and safety.

2. Material Handling and Preparation

• Load and unload materials onto the saw table, ensuring proper positioning for accurate cuts.

- Inspect materials for defects or inconsistencies that may affect cutting.

- Measure and mark materials for precise cuts based on blueprints or specifications.

- Use appropriate handling equipment, such as forklifts or overhead cranes, to move heavy materials.

3. Quality Control and Safety

• Inspect cut surfaces to ensure conformance to specifications and quality standards.

- Check for dimensions, tolerances, and surface finish.

- Identify and rectify any deviations from specifications.

- Follow established safety protocols while operating machines, handling materials, and using tools.

4. Production Monitoring and Optimization

• Monitor production processes to ensure efficiency and minimize waste

- Track production output and identify areas for improvement.

- Suggest modifications to machine settings or procedures to increase productivity.

- Maintain a clean and organized work area to promote efficiency and safety.

Interview Preparation Tips for Abrasive Sawyer

To excel in an Abrasive Sawyer interview, it is crucial to prepare thoroughly. Here are some tips and hacks to help candidates make a strong impression:

1. Research the Company and Industry

• Familiarize yourself with the company’s history, products, and market position.

- Visit the company website and study relevant industry publications.

- Gain an understanding of the industry’s best practices and emerging trends.

2. Highlight Relevant Skills and Experience

• Emphasize your proficiency in operating abrasive sawing machines and handling various materials.

- Quantify your experiences with specific examples of successful projects or contributions.

- Highlight your knowledge of abrasive wheel selection, machine setup, and cutting techniques.

- Discuss your ability to maintain machines, troubleshoot problems, and ensure safety.

3. Practice Common Interview Questions

• Prepare for basic interview questions related to your skills, experience, and motivation.

- Anticipate questions about your knowledge of machine operation, material handling, and quality control.

- Be ready to explain how you approach problem-solving and maintain a safe work environment.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

4. Show Your Passion and Enthusiasm

• Express your genuine interest in the role and the industry.

- Explain why you are passionate about abrasive sawing and how it aligns with your career goals.

- Share any relevant hobbies or projects that demonstrate your interest in working with tools and machinery.

- Convey your enthusiasm for learning and contributing to the team.

5. Prepare Thoughtful Questions

• At the end of the interview, ask thoughtful questions to demonstrate your engagement and interest.

- Inquire about the company’s production processes and growth plans.

- Ask about opportunities for professional development and career advancement.

- Show your interest in the company culture and values.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Abrasive Sawyer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.