Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Abrasive Wheel Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

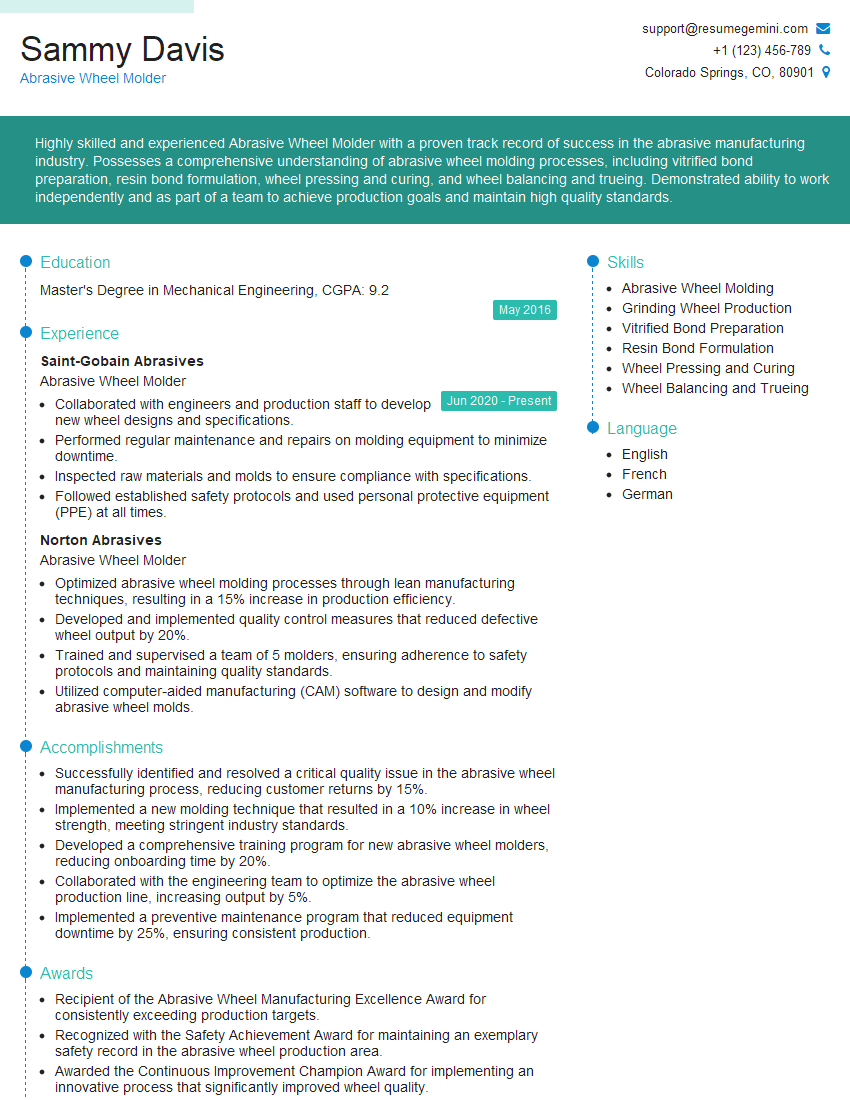

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Wheel Molder

1. What are the different types of abrasives used in making abrasive wheels?

- Natural abrasives such as corundum, emery, and garnet

- Synthetic abrasives such as silicon carbide, aluminum oxide, and cubic boron nitride

2. What is the difference between a vitrified bond and a resinoid bond?

Vitrified Bond

- Made from glass

- Strong and durable

- Can be used at high temperatures

Resinoid Bond

- Made from polymers

- Flexible and easy to grind

- Can be used at lower temperatures

3. What are the steps involved in the production of an abrasive wheel?

- Mixing the abrasive grains with a bonding agent

- Forming the mixture into a wheel shape

- Curing the wheel at high temperatures

- Dressing the wheel to the desired shape and size

4. What are the different types of abrasive wheels?

- Cylindrical Wheels

- Cup Wheels

- Segment Wheels

- Disc Wheels

- Polishing Wheels

5. What is the purpose of dressing an abrasive wheel?

- To remove the glazed surface

- To expose new abrasive grains

- To improve the cutting efficiency

6. What are the factors that affect the surface finish of a workpiece when using an abrasive wheel?

- Abrasive grit size

- Bond type

- Wheel speed

- Workpiece feed rate

7. What are the safety precautions that should be taken when using abrasive wheels?

- Wear eye protection

- Wear gloves

- Use proper mounting procedures

- Check the wheel for cracks before use

- Never operate a wheel at a speed higher than the recommended speed

8. What are the common problems that can occur when using abrasive wheels?

- Glazing

- Loading

- Vibration

- Breakage

9. How can you troubleshoot and correct problems with abrasive wheels?

- Glazing: Dress the wheel

- Loading: Clean the wheel with a brush or dressing tool

- Vibration: Check the wheel for cracks or any other damage

- Breakage: Replace the wheel

10. What are the latest trends in abrasive wheel technology?

- The development of new abrasive materials

- The use of advanced bonding systems

- The development of new wheel shapes and sizes

- The use of computer-aided manufacturing (CAM) for wheel design and production

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Wheel Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Wheel Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Abrasive Wheel Molder is primarily responsible for operating and monitoring machines that shape and form abrasive wheels. Their duties encompass:

1. Machine Operation

Operate a variety of molding machines, including automatic and semi-automatic presses, to produce abrasive wheels according to specifications.

- Set up and prepare molds, presses, and other equipment.

- Monitor machine operation and make necessary adjustments.

2. Molding and Finishing

Create abrasive wheels by pouring molten abrasive materials into molds and shaping them using pressing equipment.

- Prepare and mix abrasive materials, binders, and additives.

- Inspect and finish molded wheels to ensure accuracy and quality.

3. Quality Control

Perform quality control checks on abrasive wheels to ensure they meet specifications.

- Conduct tests, such as hardness, density, and porosity tests.

- Identify and correct any defects.

4. Equipment Maintenance

Perform basic maintenance and repairs on molding equipment.

- Lubricate and clean machines.

- Troubleshoot and resolve minor issues.

Interview Tips

To ace the interview for an Abrasive Wheel Molder position, it is crucial to:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and industry standing. Understand the specific responsibilities of the role and how they align with your skills and experience.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in operating molding machines, particularly in the abrasive wheel industry. Showcase your knowledge of abrasive materials and molding processes.

- Quantify your accomplishments with specific metrics and examples.

- Prepare examples of how you resolved challenges or implemented improvements in previous roles.

3. Demonstrate Quality-Consciousness

Stress your commitment to producing high-quality abrasive wheels. Describe your approach to quality control and how you ensure adherence to specifications.

- Explain your knowledge of industry standards and regulations.

- Share examples of how you have identified and corrected defects in the past.

4. Show Interest and Enthusiasm

Convey your passion for the role and the industry. Express your eagerness to contribute your skills and learn new technologies. Highlight your interest in the company’s products and mission.

- Ask thoughtful questions to demonstrate your knowledge and engagement.

- Be prepared to discuss your career goals and aspirations.

Next Step:

Now that you’re armed with the knowledge of Abrasive Wheel Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Abrasive Wheel Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini