Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Absorber Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

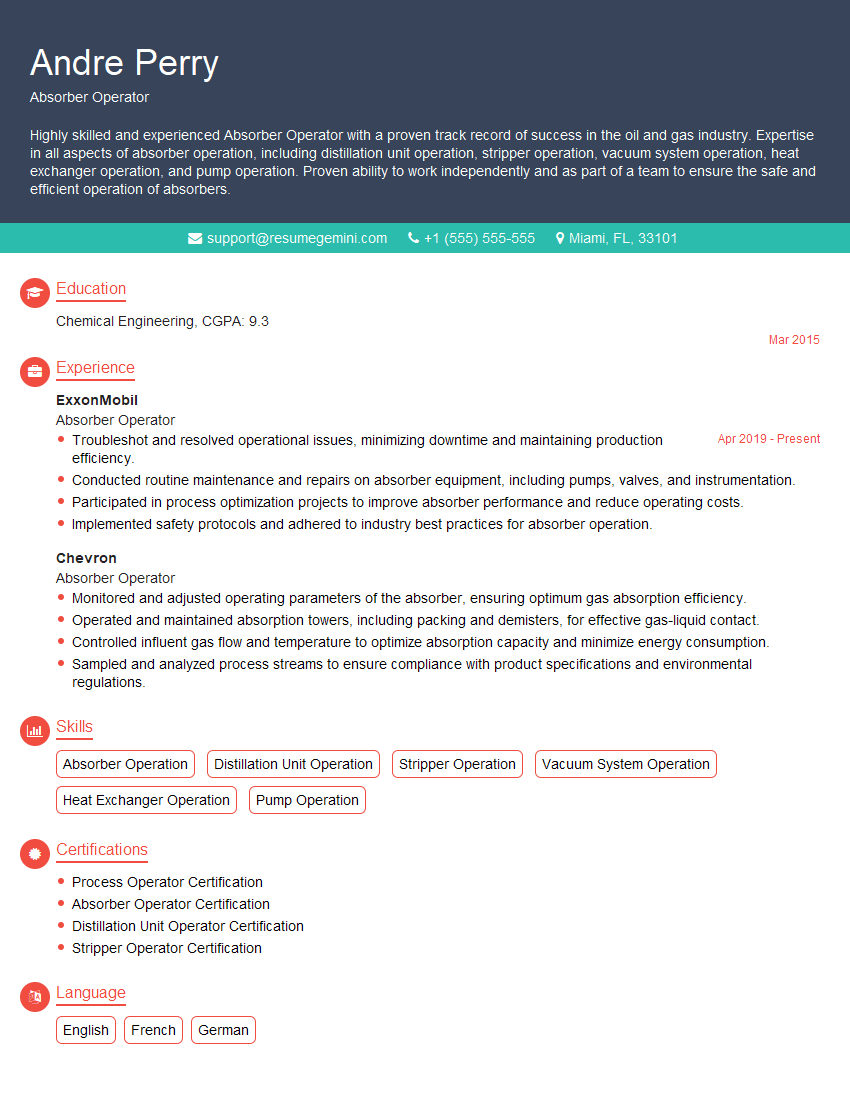

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Absorber Operator

1. What are the key responsibilities of an Absorber Operator?

As an Absorber Operator, I am responsible for:

- Operating and monitoring absorption equipment to remove impurities from gases and liquids

- Maintaining and troubleshooting absorption systems to ensure efficient operation and prevent breakdowns

- Performing quality checks on treated gases and liquids to ensure they meet specifications

- Following safety protocols and adhering to operational procedures to ensure a safe work environment

- Collaborating with other team members to optimize absorption processes and troubleshoot issues effectively

2. Describe the different types of absorbers used in chemical plants.

Packed Column Absorbers

- Use a packing material (e.g., Raschig rings, Pall rings) to increase surface area for gas-liquid contact

- Suitable for applications requiring high absorption rates and low pressure drop

Plate Column Absorbers

- Consist of a series of horizontal plates with small holes or slots

- Gas and liquid flow countercurrent through the plates, increasing contact time and enhancing absorption efficiency

- Used for applications involving high gas flow rates and moderate to high absorption rates

Spray Tower Absorbers

- Use nozzles to spray liquid droplets into a rising gas stream

- Provide a large surface area for gas-liquid contact

- Suitable for applications requiring low pressure drop and high gas flow rates

3. How do you handle fluctuations in gas flow rate or composition in an absorption system?

To handle fluctuations in gas flow rate or composition, I:

- Monitor system parameters (e.g., flow rates, pressures, temperatures) to detect changes promptly

- Adjust operating conditions (e.g., liquid flow rate, packing depth) to maintain optimal absorption efficiency

- Identify the source of the fluctuations (e.g., variations in feedstock composition, changes in process conditions)

- Communicate with upstream and downstream units to coordinate adjustments and ensure system stability

- Implement corrective measures (e.g., adjusting equipment settings, optimizing process parameters) to minimize the impact of fluctuations on product quality

4. How do you ensure the safety of an absorption system?

I prioritize safety by:

- Following established safety protocols and adhering to all safety regulations

- Wearing appropriate personal protective equipment (e.g., respirators, gloves, safety glasses)

- Inspecting equipment regularly to identify potential hazards and taking corrective actions

- Monitoring system parameters (e.g., pressure, temperature) to prevent deviations from safe operating limits

- Being aware of potential hazards associated with the chemicals being handled (e.g., corrosiveness, flammability)

- Responding promptly to any abnormal situations or emergencies and taking appropriate actions

5. What are the common troubleshooting techniques used in absorption systems?

To troubleshoot absorption systems, I use techniques such as:

- Analyzing system parameters (e.g., flow rates, pressures, temperatures) to identify deviations from normal operation

- Inspecting equipment (e.g., pumps, valves, piping) for leaks, blockages, or other issues

- Performing chemical tests on feedstock and treated products to identify any abnormalities

- Referencing technical manuals and troubleshooting guides to identify potential causes of problems

- Consulting with colleagues and technical experts to gather insights and advice

- Implementing corrective measures (e.g., adjusting operating parameters, replacing faulty components) to restore system performance

6. How do you optimize the efficiency of an absorption system?

To optimize absorption system efficiency, I:

- Monitor system performance indicators (e.g., absorption rate, energy consumption) to identify areas for improvement

- Conduct regular maintenance and inspections to ensure equipment is operating at peak efficiency

- Explore process optimization techniques (e.g., adjusting operating temperatures, optimizing packing materials) to enhance absorption rates

- Investigate new technologies and advancements in absorption systems to identify opportunities for improvement

- Collaborate with other team members and technical experts to exchange knowledge and ideas for optimizing system performance

7. What are the different types of packing materials used in absorption columns, and how do they affect absorption efficiency?

Random Packing

- Irregularly shaped materials (e.g., Raschig rings, Pall rings) that provide a large surface area for gas-liquid contact

- Used in applications where low pressure drop is critical

Structured Packing

- Ordered arrangement of sheets, grids, or tubes to create a high surface area and structured flow path

- Provides high mass transfer efficiency and reduces pressure drop compared to random packing

Choice of Packing Material

The selection of packing material depends on factors such as:

- Target absorption efficiency

- Pressure drop constraints

- Chemical compatibility with the process fluids

8. Describe the role of a solvent in an absorption process.

In an absorption process, the solvent plays a crucial role by:

- Dissolving or absorbing the target gas or liquid from the feed stream

- Increasing the surface area for contact between the gas and liquid phases

- Facilitating mass transfer between the two phases

- Regenerating the absorbent through a separate process to remove the absorbed gas or liquid

9. What are the key factors to consider when selecting an absorbent for an absorption system?

When selecting an absorbent, the following factors should be considered:

- Solubility of the target gas or liquid in the absorbent

- Chemical compatibility between the absorbent and the process fluids

- Regeneration efficiency and ease of regeneration

- Volatility and stability of the absorbent

- Cost and availability of the absorbent

10. How do you maintain and calibrate instrumentation used in absorption systems?

To maintain and calibrate instrumentation in absorption systems, I:

- Follow established maintenance schedules for regular inspections and servicing

- Use calibration equipment and procedures to ensure accuracy and reliability of sensors and transmitters

- Document maintenance and calibration activities to maintain traceability and ensure compliance

- Collaborate with instrumentation technicians or external service providers for specialized calibration and repairs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Absorber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Absorber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Absorber Operator is responsible for the safe and efficient operation of an absorber plant, a key component in the production of chemicals, pharmaceuticals, and other industrial products. Their primary tasks include:

1. Operating and Monitoring Equipment

The operator is responsible for the proper functioning of all equipment within the absorber plant, including pumps, compressors, and other machinery. They must continuously monitor gauges and controls to ensure the equipment is running smoothly and make adjustments as needed.

- Operating pumps to transfer liquid or gas through the absorber

- Monitoring and adjusting flow rates, temperatures, and pressures

- Starting, stopping, and troubleshooting equipment

2. Maintaining and Repairing Equipment

The operator is also responsible for maintaining and repairing equipment within the plant. This may include replacing filters, cleaning pumps, and performing minor repairs. They must be able to identify and resolve problems quickly to minimize downtime.

- Replacing filters and cleaning equipment

- Performing minor repairs, such as replacing seals or gaskets

- Lubricating and greasing equipment

3. Monitoring Production

The operator is responsible for monitoring production levels and ensuring that the plant is running at optimal capacity. They may collect samples and perform tests to ensure that the absorber is producing the desired product quality.

- Monitoring production rates and yields

- Collecting samples and performing tests to ensure product quality

- Adjusting operating parameters to optimize production

4. Safety and Environmental Compliance

The operator is responsible for ensuring a safe and healthy work environment. They must follow all safety procedures and regulations, and they must be aware of the potential hazards associated with the chemicals and processes used in the plant.

- Following all safety procedures and regulations

- Using appropriate personal protective equipment

- Responding to emergencies

Interview Tips

Preparing thoroughly for an interview is crucial. Here are some tips to help you ace your interview for an Absorber Operator position:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, its products or services, and the key responsibilities of the role. You can find this information on the company’s website, social media pages, and industry news articles.

- Visit the company’s website to learn about their history, mission, products, and services.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read industry news articles to stay up-to-date on the latest trends and developments in the field.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in interviews for Absorber Operator positions. It’s a good idea to practice answering these questions ahead of time so that you can deliver confident and well-thought-out responses. Some common interview questions include:

- Tell me about your experience operating and maintaining absorber equipment.

- What are the most important safety considerations when working in an absorber plant?

- How do you handle unexpected situations or equipment malfunctions?

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the Absorber Operator position. Be specific and provide examples of how you’ve used your skills to achieve success in previous roles. For example, you could mention your experience in operating and maintaining pumps, compressors, and other equipment. You could also discuss your knowledge of safety procedures and regulations, and your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated an absorber plant,” you could say “I operated an absorber plant and increased production by 15%.”

- Use action verbs to describe your skills and experience. For example, instead of saying “I am responsible for safety,” you could say “I enforce safety regulations and procedures.”

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you’re serious about the position. You should also be prepared to answer questions about your experience and qualifications, and to ask questions about the company and the position.

- Choose clothing that is clean, pressed, and fits well.

- Arrive at the interview location 10-15 minutes early to give yourself time to relax and prepare.

Next Step:

Now that you’re armed with the knowledge of Absorber Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Absorber Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini