Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Absorption and Adsorption Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

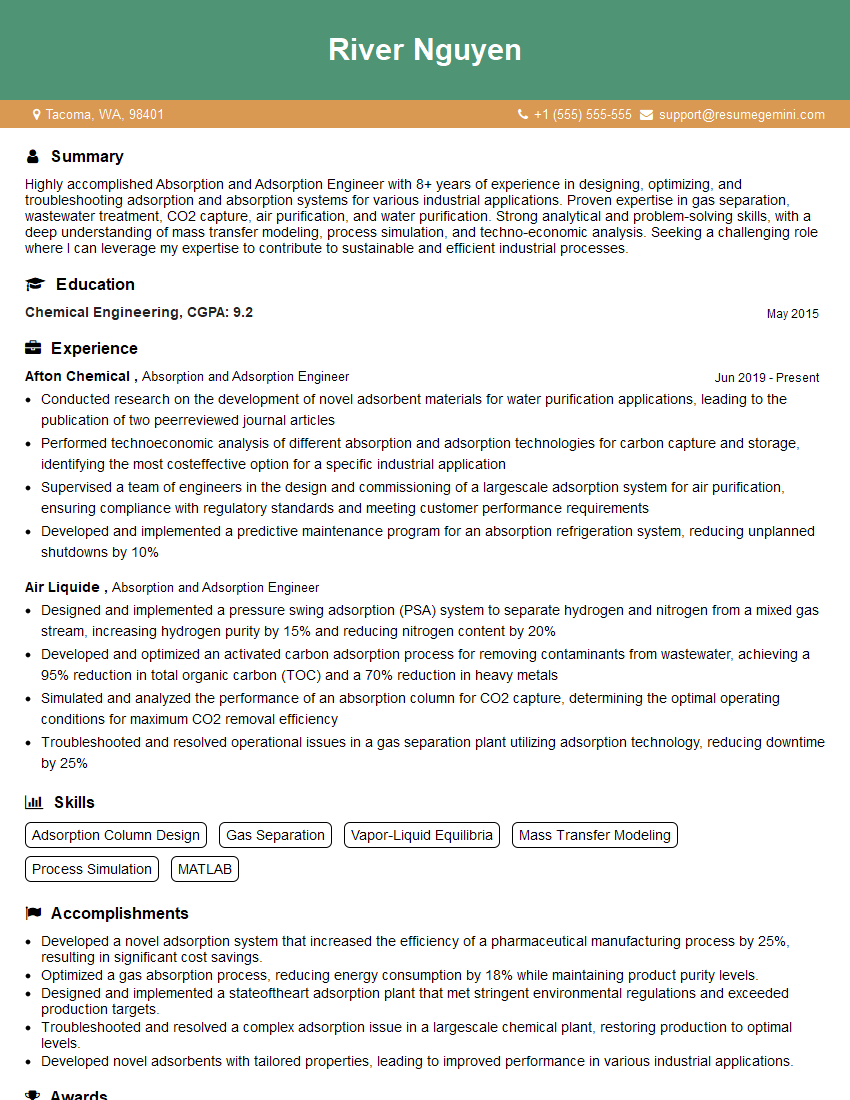

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Absorption and Adsorption Engineer

1. What is the difference between absorption and adsorption?

- Absorption is a process in which a substance is taken into the bulk of another substance. The absorbed substance is distributed throughout the volume of the absorbent.

- Adsorption is a process in which a substance is taken onto the surface of another substance. The adsorbed substance is confined to the surface of the adsorbent.

2. What are the different types of absorption processes?

Types of absorption processes

- Physical absorption occurs when a substance dissolves in another substance without forming a chemical bond. This type of absorption is common in liquids and gases.

- Chemical absorption occurs when a substance reacts with another substance to form a chemical bond. This type of absorption is common in solids and liquids.

3. What are the different types of adsorption processes?

The different types of adsorption processes include

- Physical adsorption occurs when a substance is adsorbed onto the surface of another substance by van der Waals forces. This type of adsorption is common in gases and liquids.

- Chemical adsorption occurs when a substance is adsorbed onto the surface of another substance by chemical bonding. This type of adsorption is common in solids and liquids.

4. What are the factors that affect the rate of absorption?

The factors that affect the rate of absorption include

- The concentration of the substance being absorbed

- The temperature of the system

- The surface area of the absorbent

- The rate of agitation

5. Give an example of an industrial application of absorption.

An example of an industrial application of absorption is the absorption of carbon dioxide from flue gases. In this process, carbon dioxide is absorbed into a solvent, such as monoethanolamine (MEA). The MEA is then regenerated by heating, which drives off the carbon dioxide.

6. Give an example of an industrial application of adsorption.

An example of an industrial application of adsorption is the adsorption of water vapor from air. In this process, water vapor is adsorbed onto a solid adsorbent, such as silica gel or activated carbon. The adsorbent is then regenerated by heating, which drives off the water vapor.

7. What are the advantages and disadvantages of absorption processes?

Advantages of absorption processes

- High efficiency

- Low energy consumption

- Scalability

Disadvantages of absorption processes

- Cost of the solvent

- Potential for solvent loss

- Environmental concerns

8. What are the advantages and disadvantages of adsorption processes?

Advantages of adsorption processes

- High efficiency

- Low energy consumption

- Simple to operate

Disadvantages of adsorption processes

- Cost of the adsorbent

- Potential for adsorbent loss

- Environmental concerns

9. What are the different types of adsorbents?

The different types of adsorbents include

- Activated carbon

- Silica gel

- Zeolites

- Metal-organic frameworks (MOFs)

10. How do you design an absorption or adsorption process?

The design of an absorption or adsorption process involves the following steps:

- Identify the process objectives

- Select the appropriate technology

- Design the process equipment

- Optimize the process operating conditions

- Monitor and control the process

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Absorption and Adsorption Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Absorption and Adsorption Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Absorption and Adsorption Engineer is responsible for the design, development, and operation of absorption and adsorption systems. This includes:1. Design and Development

- Designing and developing absorption and adsorption systems for a variety of applications, including gas separation, purification, and drying.

- Conducting research and development to improve the efficiency and performance of absorption and adsorption systems.

- Working with other engineers and scientists to develop new technologies and products.

2. Operation and Maintenance

- Operating and maintaining absorption and adsorption systems to ensure they are operating at peak efficiency.

- Troubleshooting and repairing absorption and adsorption systems.

- Performing routine maintenance and inspections to ensure the systems are operating safely and efficiently.

3. Process Engineering

- Developing and optimizing process parameters for absorption and adsorption systems.

- Conducting process simulations to predict the performance of absorption and adsorption systems.

- Working with other engineers and scientists to develop and implement process improvements.

4. Project Management

- Managing projects related to the design, development, and operation of absorption and adsorption systems.

- Working with vendors and contractors to procure and install equipment.

- Ensuring that projects are completed on time and within budget.

Interview Tips

To ace an interview for an Absorption and Adsorption Engineer position, it is important to be prepared and have a strong understanding of the following:1. Technical Skills

- Absorption and adsorption theory

- Process simulation

- Heat and mass transfer

- Chemical engineering principles

2. Industry Knowledge

- Applications of absorption and adsorption systems

- Current trends in absorption and adsorption technology

- Major players in the absorption and adsorption industry

3. Soft Skills

- Communication skills

- Teamwork skills

- Problem-solving skills

- Critical thinking skills

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Absorption and Adsorption Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!