Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Acetylene Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

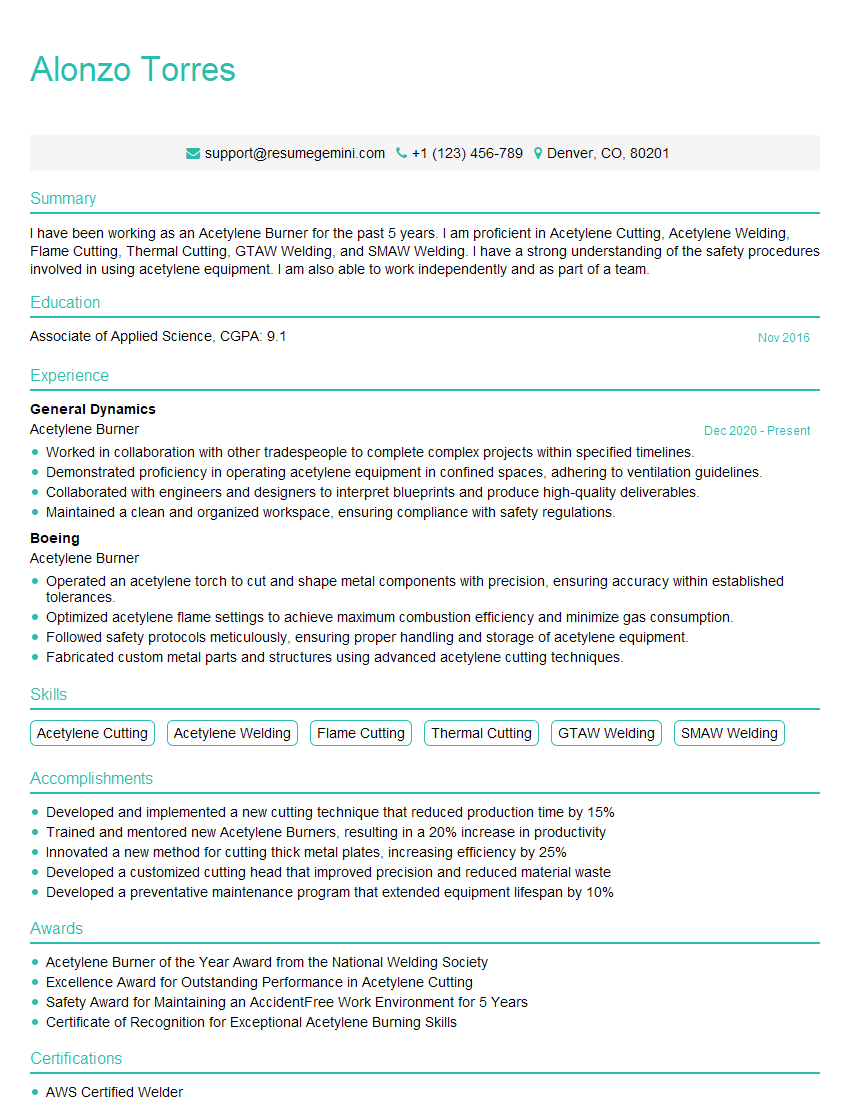

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Burner

1. Explain the process of setting up and operating an acetylene burner.

The process of setting up and operating an acetylene burner involves the following steps:

- Inspect the equipment: Verify that the acetylene tank, hoses, and torch are in good condition and free from any damage or leaks.

- Secure the tank: Place the acetylene tank upright in a stable location and secure it with a chain or strap.

- Connect the hoses: Attach the acetylene hose to the tank and the torch, ensuring that the connections are tight and leak-free.

- Purge the hoses: Open the tank valve slightly to purge any air from the hoses. Close the valve and check for leaks using soapy water.

- Light the torch: Hold a spark lighter near the torch tip and open the acetylene valve slightly. Adjust the oxygen valve to obtain a neutral flame.

- Adjust the flame: Regulate the flow of acetylene and oxygen to achieve the desired flame size and shape. A neutral flame is typically used for welding, while a carburizing flame is preferred for cutting.

2. Describe the safety precautions that should be taken when working with an acetylene burner.

Personal Protective Equipment

- Wear appropriate personal protective equipment (PPE), including leather gloves, safety glasses, and a welding helmet.

- Ensure that the work area is well-ventilated to prevent the accumulation of acetylene gas.

Preventing Backfire

- Never open the acetylene valve before the oxygen valve.

- Always light the torch away from the workpiece.

- Keep the torch tip clean and free from slag.

Handling Tanks

- Handle acetylene tanks with care and avoid dropping or rolling them.

- Store tanks in a cool, dry, and well-ventilated area.

- Never use an acetylene tank that has been damaged or has exceeded its service life.

3. What are the different types of acetylene burners available, and what are their specific applications?

- Hand-held torches: Used for cutting, welding, and brazing in close-quarters.

- Manifold torches: Used for larger-scale welding and cutting operations.

- Machine torches: Integrated into automated welding or cutting machines for high-volume production.

- Underwater torches: Specially designed for welding and cutting underwater.

- Specialized torches: Designed for specific applications, such as brazing, pipe welding, or surface hardening.

4. How do you troubleshoot common problems that occur when using an acetylene burner?

- Backfire: Caused by incorrect gas flow or a dirty torch tip. Clean the tip and adjust the gas flow accordingly.

- Flashback: Oxygen entering the acetylene hose. Close the acetylene valve and relight the torch.

- Leaking hoses: Check the hose connections for tightness and replace any damaged hoses.

- Poor flame quality: Adjust the gas flow to achieve a neutral flame. Clean the torch tip if necessary.

- Torch overheating: Allow the torch to cool down and avoid using it continuously for extended periods.

5. What are the key characteristics of a high-quality acetylene burner?

- Durable construction: Made from high-quality materials that can withstand the heat and pressure of acetylene combustion.

- Precise gas control: Valves allow for fine-tuning of the gas flow to achieve the desired flame settings.

- Ergonomic design: Designed for comfortable and prolonged use.

- Reliable ignition: Consistent and easy to light.

- Safety features: Equipped with safety devices to prevent backfire and flashback.

6. How do you maintain an acetylene burner to ensure its optimal performance and safety?

- Regular cleaning: Clean the torch tip and mixer regularly to remove slag and debris.

- Hose inspection: Check hoses for leaks and damage. Replace any damaged hoses immediately.

- Tank maintenance: Store tanks in a cool, dry, and well-ventilated area. Inspect tanks for leaks or damage before use.

- Valve maintenance: Keep valves clean and lubricated to ensure proper gas flow.

- Training and certification: Ensure that operators are properly trained and certified in the safe use of acetylene burners.

7. Describe the different types of fuel gases that can be used with an acetylene burner and their respective advantages and disadvantages.

- Acetylene: Produces a hot, luminous flame with a high calorific value. However, it can be explosive when mixed with air.

- Propane: Produces a clean, soot-free flame. It is less hazardous than acetylene but has a lower calorific value.

- MAPP gas: A blend of propane and methylacetylene-propadiene. It produces a hotter flame than propane but is more expensive.

- Natural gas: A readily available and economical fuel. However, it produces a lower calorific value and requires a larger torch tip.

8. Explain the role of oxygen in the acetylene burning process.

- Oxygen combines with acetylene to create a high-temperature flame.

- The amount of oxygen supplied determines the type of flame produced.

- A neutral flame is used for welding, while a carburizing flame is used for cutting.

9. Discuss the importance of torch tip selection for different acetylene burning applications.

- The size and shape of the torch tip determine the flame characteristics.

- Smaller tips produce a concentrated flame for precision welding.

- Larger tips produce a broader flame for larger-scale heating or cutting.

10. Explain the potential hazards associated with the improper use of an acetylene burner.

- Fire: Acetylene is highly flammable and can ignite easily.

- Explosion: Acetylene can form explosive mixtures with air.

- Burns: The torch flame and hot metal can cause severe burns.

- Eye injuries: UV radiation from the flame can damage the eyes.

- Asphyxiation: Acetylene is an asphyxiant and can displace oxygen in confined spaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Acetylene Burner, you will be responsible for handling and deploying acetylene burners in a safe and efficient manner. Your primary duties will include cutting, welding, and brazing various materials using the appropriate techniques and safety protocols.

1. Cutting and Welding

Operate acetylene burners to cut and weld metal pieces to exact specifications.

- Use appropriate techniques for different metals, thicknesses, and shapes.

- Ensure precise cuts and welds that meet required standards.

2. Brazing

Perform brazing operations to join metal surfaces using appropriate brazing alloys.

- Prepare surfaces, apply fluxes, and heat materials to the proper temperature.

- Inspect and test brazed joints for soundness and strength.

3. Equipment Maintenance

Maintain and inspect acetylene burners and related equipment regularly.

- Clean and adjust burners, replace tips, and ensure proper functioning.

- Monitor gas pressure, flow rates, and other parameters for safety and efficiency.

4. Safety and Compliance

Strictly adhere to all safety regulations and protocols related to acetylene burning.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Handle and store acetylene gas safely to prevent accidents and ensure compliance with regulations.

Interview Tips

To ace your interview for an Acetylene Burner position, consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the acetylene burning industry, its applications, and the specific requirements of the company you are interviewing with.

- Review industry websites and publications to stay up-to-date on best practices and technologies.

- Visit the company’s website to learn about their products, services, and safety standards.

2. Highlight Your Skills and Experience

Emphasize your proficiency in acetylene burning techniques, including cutting, welding, and brazing. Quantify your experience with specific examples and results.

- Describe projects where you successfully cut and welded complex shapes or repaired damaged equipment.

- Showcase your ability to handle and store acetylene gas safely and comply with regulations.

3. Demonstrate Your Safety Consciousness

Safety is paramount in acetylene burning. Assure the interviewer of your commitment to adhering to safety protocols and your understanding of potential hazards.

- Explain your knowledge of PPE, proper equipment handling, and gas storage procedures.

- Share examples of how you prioritize safety in your previous work experience.

4. Ask Insightful Questions

To show your engagement and interest, prepare thoughtful questions about the company, the role, and the industry.

- Inquire about the company’s safety policies and training programs.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acetylene Burner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.