Are you gearing up for a career in Acetylene Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Acetylene Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

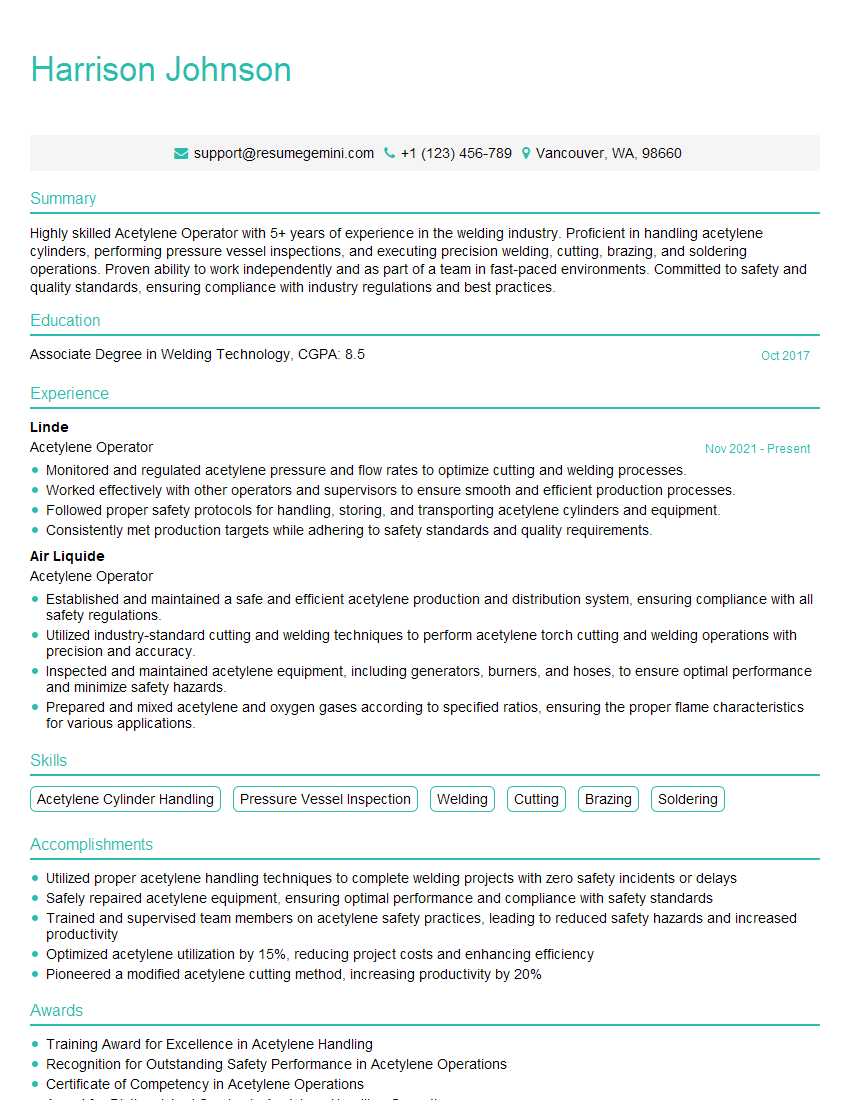

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Operator

1. Explain the proper procedure for setting up and operating an acetylene generator.

- Prepare the generator by opening the water drain valve and flushing it with clean water.

- Install the carbide basket and fill it with carbide.

- Close the water drain valve and slowly open the water supply valve, allowing water to enter the generator.

- Adjust the water level to maintain a constant flow of acetylene.

- Monitor the pressure gauge and adjust the water flow accordingly to maintain a safe operating pressure.

2. What are the safety precautions that must be taken when working with acetylene?

Fire and Explosion Hazards

- Acetylene is highly flammable and can easily ignite, so open flames, sparks, or heated surfaces must be avoided.

- Never smoke or use naked flames around acetylene equipment.

- Keep acetylene cylinders away from heat sources and protect them from physical damage.

Toxic Hazards

- Acetylene can cause dizziness, headaches, and nausea. Adequate ventilation must be provided to prevent these effects.

- Avoid breathing acetylene directly and wear a respirator when working in confined spaces.

3. How do you troubleshoot a clogged acetylene generator?

- Check the water level in the generator and adjust if necessary.

- Inspect the carbide basket for any obstructions and remove them.

- Check the water drain valve and ensure it is fully open.

- Inspect the hoses and connections for any leaks or blockages.

- If the problem persists, contact a qualified technician for assistance.

4. Describe the different types of acetylene torches and their uses.

- Neutral Flame Torch: Produces an oxidizing flame that can be used for welding, cutting, and brazing mild steel.

- Oxidizing Flame Torch: Produces a flame with excess oxygen that increases the temperature and is suitable for cutting metal.

- Carburizing Flame Torch: Produces a flame with excess acetylene that reduces oxides and is used for welding cast iron and other ferrous metals.

5. What are the benefits of using acetylene for welding and cutting compared to other fuels?

- Acetylene produces a hotter flame than other fuels, resulting in faster cutting and welding speeds.

- Acetylene is versatile and can be used for a wide range of applications, including welding, cutting, and brazing.

- Acetylene is relatively easy to handle and transport.

6. How do you maintain an acetylene torch properly?

- Clean the torch tip and mixer regularly to prevent clogging.

- Inspect the hoses and connections for leaks or damage.

- Store the torch in a dry and well-ventilated area when not in use.

- Follow the manufacturer’s instructions for specific maintenance procedures.

7. What are the potential hazards of backfire when using an acetylene torch?

- Backfire occurs when the flame travels back into the torch, creating a loud noise and intense heat.

- The backfire can cause serious injuries to the operator and damage to the equipment.

- Backfire can be prevented by using a proper torch technique, maintaining the correct flame settings, and inspecting the equipment regularly.

8. Describe the proper procedures for storing and handling acetylene cylinders.

- Acetylene cylinders must be stored upright and secured to prevent them from falling.

- Cylinders should be stored in a well-ventilated area away from heat sources and incompatible materials.

- Acetylene cylinders should never be stored indoors or in confined spaces.

- Cylinders must be handled with care and never dropped or rolled.

9. What are the key factors that affect the quality of a weld when using an acetylene torch?

- Proper flame adjustment and torch technique

- Cleanliness of the base metal

- Joint preparation

- Welding speed and travel angle

- Filler metal selection

10. Describe the process of brazing with an acetylene torch.

- Clean the surfaces to be joined.

- Apply a flux to promote bonding.

- Heat the metal with an acetylene torch.

- Add a brazing alloy to the joint.

- Continue heating the joint until the brazing alloy flows and fills the gap.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Acetylene Operator is responsible for monitoring and maintaining acetylene producing machinery, ensuring safe production and adherence to quality standards. Their key duties include:

1. Acetylene Production and Monitoring

Oversee the acetylene generating equipment, regulating parameters like temperature, pressure, and flow rates.

- Monitor and control the various chemical reactions involved in the acetylene production process.

- Analyze gas samples to ensure the composition meets specifications and make adjustments as needed.

2. Equipment Maintenance and Repair

Perform routine maintenance on acetylene production equipment, including inspection, cleaning, and lubrication.

- Identify and resolve minor equipment malfunctions promptly to minimize downtime.

- Coordinate with maintenance personnel for major repairs and overhauls.

3. Safety and Compliance

Uphold a safe and compliant work environment, adhering to established safety protocols and regulations.

- Inspect and maintain safety equipment such as fire extinguishers and alarm systems.

- Monitor and control hazardous gas levels, taking appropriate action in the event of a leak or emergency.

4. Documentation and Reporting

Maintain accurate and up-to-date records of acetylene production, equipment maintenance, and any deviations from standard operating procedures.

- Prepare reports on acetylene production yields, equipment performance, and any safety incidents.

- Communicate production and maintenance data to supervisors and relevant personnel.

Interview Tips

To ace an interview for an Acetylene Operator position, it is essential to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Role and Company

Familiarize yourself with the specific job responsibilities and the company’s industry and values.

- Review the job description carefully and identify the skills and qualifications the interviewer is seeking.

- Visit the company website to learn about their products, services, and business culture.

2. Highlight Relevant Experience

Emphasize your experience with acetylene production, equipment operation, and safety protocols.

- Quantify your accomplishments using specific examples and data whenever possible.

- Discuss how your previous experience has prepared you for the responsibilities of an Acetylene Operator.

3. Demonstrate Safety and Compliance Knowledge

Show that you understand and prioritize safety in the workplace.

- Highlight your training and experience in handling hazardous materials and adhering to safety regulations.

- Explain how you would respond to potential safety hazards and emergencies related to acetylene production.

4. Prepare for Technical Questions

Anticipate questions about the technical aspects of acetylene production and equipment operation.

- Review the basics of acetylene chemistry, production processes, and equipment troubleshooting.

- Be prepared to discuss your understanding of relevant safety standards and industry best practices.

5. Practice Your Communication Skills

Convey your technical knowledge and experience clearly and confidently.

- Practice answering common interview questions and prepare concise and well-articulated responses.

- Be prepared to ask thoughtful questions that demonstrate your interest in the role and the company.

Next Step:

Now that you’re armed with the knowledge of Acetylene Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Acetylene Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini