Are you gearing up for a career in Acetylene Plant Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Acetylene Plant Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

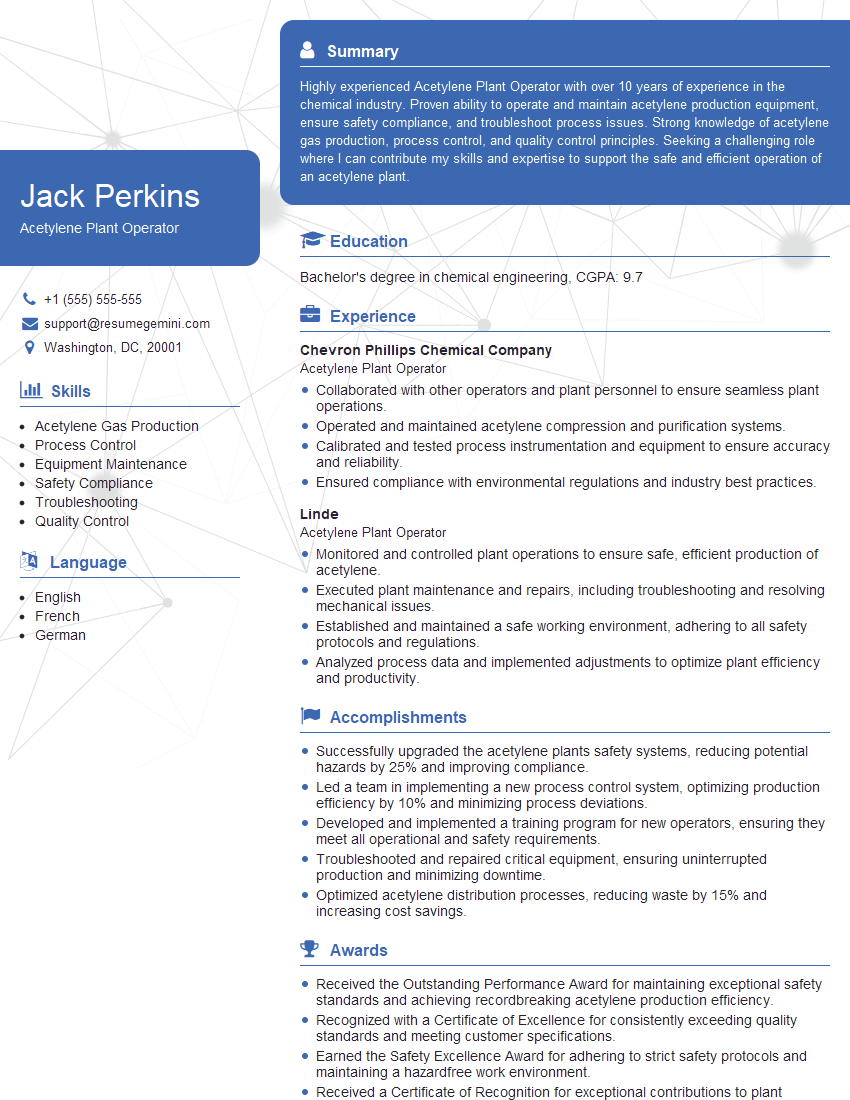

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Plant Operator

1. Describe the process of producing acetylene in an acetylene plant?

The process of producing acetylene in an acetylene plant involves several steps:

- Raw material preparation: Calcium carbide, the primary raw material, is crushed and sized to ensure uniform particle distribution.

- Reaction chamber: The crushed calcium carbide is fed into a reaction chamber, where it reacts with water to form acetylene gas.

- Purification: The acetylene gas produced contains impurities such as hydrogen sulfide, phosphine, and ammonia. These impurities are removed through a purification process.

- Compression and storage: The purified acetylene gas is compressed into cylinders or tanks for storage and transportation.

2. Explain the safety precautions that must be observed while operating an acetylene plant?

General safety measures:

- Wear appropriate personal protective equipment (PPE).

- Follow proper operating procedures and safety protocols.

- Maintain a clean and organized work area.

- Regularly inspect equipment and report any issues promptly.

Acetylene-specific hazards:

- Fire and explosion: Acetylene is a highly flammable and explosive gas. Precautions must be taken to prevent leaks, sparks, and open flames.

- Toxicity: Inhalation of acetylene gas can be harmful to health. Proper ventilation is essential.

3. What are the different types of equipment used in an acetylene plant, and how do they function?

- Calcium carbide feeder: Controls the flow of calcium carbide into the reaction chamber.

- Reaction chamber: Where calcium carbide reacts with water to produce acetylene gas.

- Gas scrubber: Removes impurities from the acetylene gas.

- Compressor: Compresses the purified acetylene gas for storage.

- Storage tanks: Store the compressed acetylene gas safely and securely.

- Monitoring and control systems: Monitor and regulate plant operations, including temperature, pressure, and gas flow.

4. How do you troubleshoot and resolve common problems that may occur in an acetylene plant?

- Low acetylene yield: Check the calcium carbide quality, water flow, and reaction chamber temperature.

- Impurities in the gas: Inspect the gas scrubber and ensure it is functioning properly.

- Equipment malfunction: Identify the affected component, follow troubleshooting procedures, and contact maintenance if necessary.

- Gas leaks: Use a leak detector to identify and seal any leaks promptly.

- Safety concerns: Follow established emergency protocols and evacuate personnel if necessary.

5. How do you ensure the quality of the acetylene produced in the plant?

- Raw material inspection: Verify the quality of calcium carbide before use.

- Process control: Monitor and maintain optimal reaction conditions.

- Purification efficiency: Regularly check the performance of the gas scrubber.

- Product testing: Regularly sample and analyze the produced acetylene gas to meet specifications.

- Quality management system: Implement and follow established quality standards and procedures.

6. Describe the maintenance procedures for the equipment used in an acetylene plant?

- Regular inspections: Visually inspect equipment for wear, leaks, and damage.

- Cleaning and lubrication: Clean and lubricate moving parts as per manufacturer’s recommendations.

- Calibration: Regularly calibrate instruments and sensors to ensure accuracy.

- Preventive maintenance: Perform scheduled maintenance tasks to identify and address potential issues.

- Emergency repairs: Address any equipment malfunctions or breakdowns promptly to minimize downtime.

7. How do you handle and store acetylene safely?

- Use appropriate containers and equipment specifically designed for acetylene storage.

- Store acetylene in a cool, well-ventilated area away from heat sources.

- Secure cylinders upright and prevent them from falling or rolling.

- Keep acetylene away from incompatible materials and potential ignition sources.

- Follow established safety protocols for handling and transporting acetylene.

8. Can you describe the chemical reactions involved in the production of acetylene from calcium carbide?

The main chemical reaction involved in the production of acetylene from calcium carbide is:

CaC2 + 2H2O → C2H2 + Ca(OH)2

- Calcium carbide reacts with water to form acetylene gas and calcium hydroxide.

9. What are the key challenges in operating an acetylene plant and how do you overcome them?

- Ensuring safety: Implementing strict safety protocols, providing proper training, and maintaining a high level of vigilance.

- Maintaining product quality: Controlling process parameters, monitoring equipment performance, and conducting regular quality checks.

- Minimizing environmental impact: Using efficient technologies, treating wastewater, and adhering to environmental regulations.

- Optimizing production: Continuously evaluating and improving processes, reducing downtime, and increasing efficiency.

- Managing costs: Controlling raw material costs, optimizing energy consumption, and implementing cost-saving measures.

10. How do you stay updated with the latest advancements and best practices in acetylene production?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with other professionals in the field.

- Participating in training programs.

- Staying informed about regulatory changes and industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Acetylene Plant Operator is responsible for the day-to-day operations of an acetylene plant. This includes monitoring and controlling the production process, performing maintenance on equipment, and ensuring the safety of the plant.

1. Monitor and control the production process

The Acetylene Plant Operator is responsible for monitoring and controlling the production process to ensure that acetylene is produced safely and efficiently. This includes:

- Monitoring the temperature, pressure, and flow rate of the reactants and products.

- Adjusting the process parameters to optimize production.

- Troubleshooting any problems that occur during the production process.

2. Perform maintenance on equipment

The Acetylene Plant Operator is responsible for performing maintenance on equipment to ensure that it is operating safely and efficiently. This includes:

- Inspecting equipment for wear and tear.

- Replacing worn or damaged parts.

- Lubricating and cleaning equipment.

3. Ensure the safety of the plant

The Acetylene Plant Operator is responsible for ensuring the safety of the plant. This includes:

- Following all safety procedures.

- Identifying and mitigating potential hazards.

- Responding to emergencies.

4. Other duties

In addition to the above, the Acetylene Plant Operator may also be responsible for:

- Training new employees.

- Maintaining records.

- Performing other tasks as assigned.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go on an interview, it is important to do your research on the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Prepare a few questions to ask the interviewer.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Choose clothes that are comfortable and allow you to move around easily.

- Avoid wearing clothes that are too revealing or too casual.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time.

- Plan your route ahead of time and allow yourself extra time for traffic or unexpected delays.

- If you are running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

- Don’t be afraid to ask questions.

- Be honest and open about your skills and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Acetylene Plant Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.