Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Acetylene Torch Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

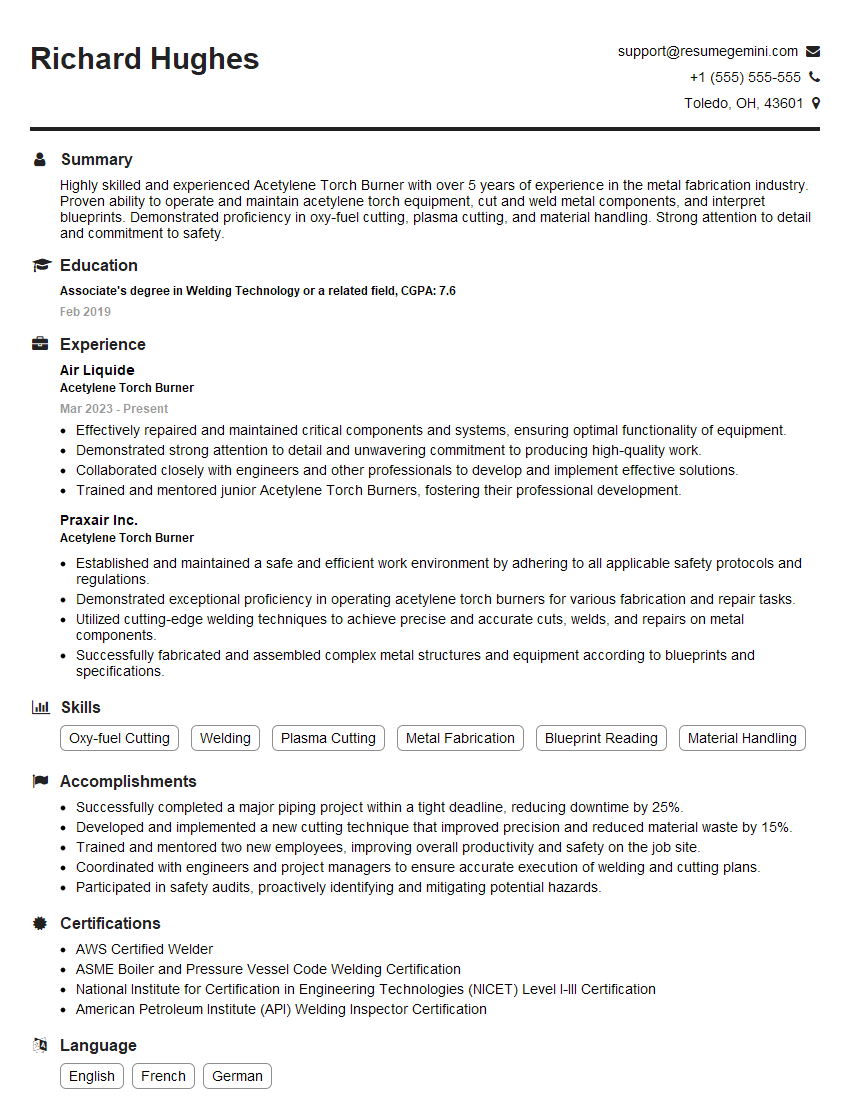

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Torch Burner

1. What are the primary components of an acetylene torch burner and their functions?

- Tip: Mixes fuel gases (acetylene and oxygen) and directs the flame.

- Mixer: Controls the flow of gases and creates a stable flame.

- Handle: Provides a grip for the operator.

- Valve(s): Regulates the flow of gases to the tip.

- Hoses: Connect the burner to the gas supply.

2. Describe the correct procedure for setting up an acetylene torch burner.

Safety Precautions

- Wear appropriate safety gear (gloves, eye protection, flame-resistant clothing).

- Ensure the work area is clear and well-ventilated.

Setup Steps

- Connect the hoses to the gas supply and the burner.

- Open the oxygen valve slightly and hold a lit match to the tip to ignite the pilot flame.

- Open the acetylene valve gradually while adjusting the oxygen valve to achieve the desired flame.

- Check the flame appearance, ensure it is a neutral flame (blue cone with a white tip).

3. What types of fuel gases can be used in an acetylene torch burner?

Acetylene is the primary fuel gas, but other options include:

- Propane

- Natural gas (methane)

- Butane

- Hydrogen

4. How do you adjust the flame to different cutting and welding applications?

By adjusting the relative flow rates of acetylene and oxygen:

- Cutting: Higher oxygen flow rate, resulting in a neutral flame (blue cone with a white tip).

- Welding: Slightly reduced oxygen flow rate, resulting in a slightly carburizing flame (feathery blue cone with a yellow tip).

5. What are the different types of welding techniques that can be performed with an acetylene torch burner?

- Oxy-fuel welding: Joining two pieces of metal using a filler metal.

- Brazing: Joining two pieces of metal using a lower-temperature filler metal.

- Soldering: Joining two pieces of metal using a low-melting-point solder.

- Cutting: Separating metal pieces using the high temperature of an oxidizing flame.

6. What are the safety precautions that must be followed when operating an acetylene torch burner?

- Wear appropriate safety gear.

- Keep the work area well-ventilated.

- Use a back-flash arrestor in the torch handle.

- Never open the acetylene valve before the oxygen valve.

- Inspect hoses and equipment regularly.

- Store acetylene cylinders upright.

7. How do you troubleshoot a faulty acetylene torch burner?

- No flame: Check gas supply, connections, and ignition system.

- Back-firing: Adjust gas flow rates, check for restrictions in the tip.

- Carbon build-up on the tip: Clean the tip using a wire brush.

- Hissing sound: Check for leaks in hoses or connections.

- Uneven flame: Adjust gas flow rates, clean the tip.

8. Can you describe the importance of using different tip sizes for different applications?

Tip size affects flame size and heat intensity:

- Small tips: Precision work, thin materials.

- Medium tips: General welding, cutting.

- Large tips: Heavy welding, thick materials.

9. What are the potential hazards associated with using acetylene torch burners?

- Fire and explosion: Acetylene is a flammable gas.

- Burns: From the high flame temperature.

- Eye damage: From harmful UV radiation.

- Oxygen deficiency: Acetylene combustion consumes oxygen.

- Toxic fumes: From impurities in acetylene.

10. How do you maintain an acetylene torch burner in good working order?

- Clean the tip regularly.

- Inspect hoses and connections for damage.

- Lubricate moving parts.

- Store the torch in a dry, well-ventilated area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Torch Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Torch Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Acetylene Torch Burner is responsible for safely and effectively operating an acetylene torch to cut and shape metal. They must have a strong understanding of the hazards associated with working with acetylene and be able to follow safety protocols. Additional responsibilities include:

1. Set up and operate acetylene torch

Acetylene Torch Burners are responsible for setting up and operating the acetylene torch. This involves connecting the torch to the acetylene and oxygen tanks, adjusting the gas flow, and lighting the torch. They must also be able to troubleshoot any problems that may occur with the torch.

2. Cut and shape metal

Acetylene Torch Burners use the acetylene torch to cut and shape metal. This involves guiding the torch along the desired cutting line and using the correct torch technique to achieve the desired results. They must be able to cut and shape metal to precise dimensions.

3. Weld metal

Acetylene Torch Burners can also use the acetylene torch to weld metal. This involves melting the edges of two pieces of metal together and then joining them together. They must be able to weld metal to create strong and durable joints.

4. Maintain equipment

Acetylene Torch Burners are responsible for maintaining the acetylene torch and related equipment. This involves cleaning the torch, checking for leaks, and replacing any worn or damaged parts.

Interview Tips

To ace the interview for an Acetylene Torch Burner position, it is important to prepare thoroughly. Here are some tips:

1. Research the company

Before the interview, take some time to research the company. This will help you understand the company’s culture, values, and goals. You should also learn about the specific role you are interviewing for and the company’s expectations for the position.

2. Practice your answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Common interview questions for Acetylene Torch Burners include:

- Tell me about your experience with acetylene torches.

- What are the safety hazards associated with working with acetylene?

- How do you set up and operate an acetylene torch?

- What are the different types of cuts and welds you can make with an acetylene torch?

- How do you maintain an acetylene torch and related equipment?

3. Dress professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also make sure your hair is neat and your shoes are polished.

4. Be on time

Punctuality is important, so make sure you arrive for the interview on time. If you are running late, call the interviewer and let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acetylene Torch Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!