Feeling lost in a sea of interview questions? Landed that dream interview for Acetylene Torch Solderer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Acetylene Torch Solderer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

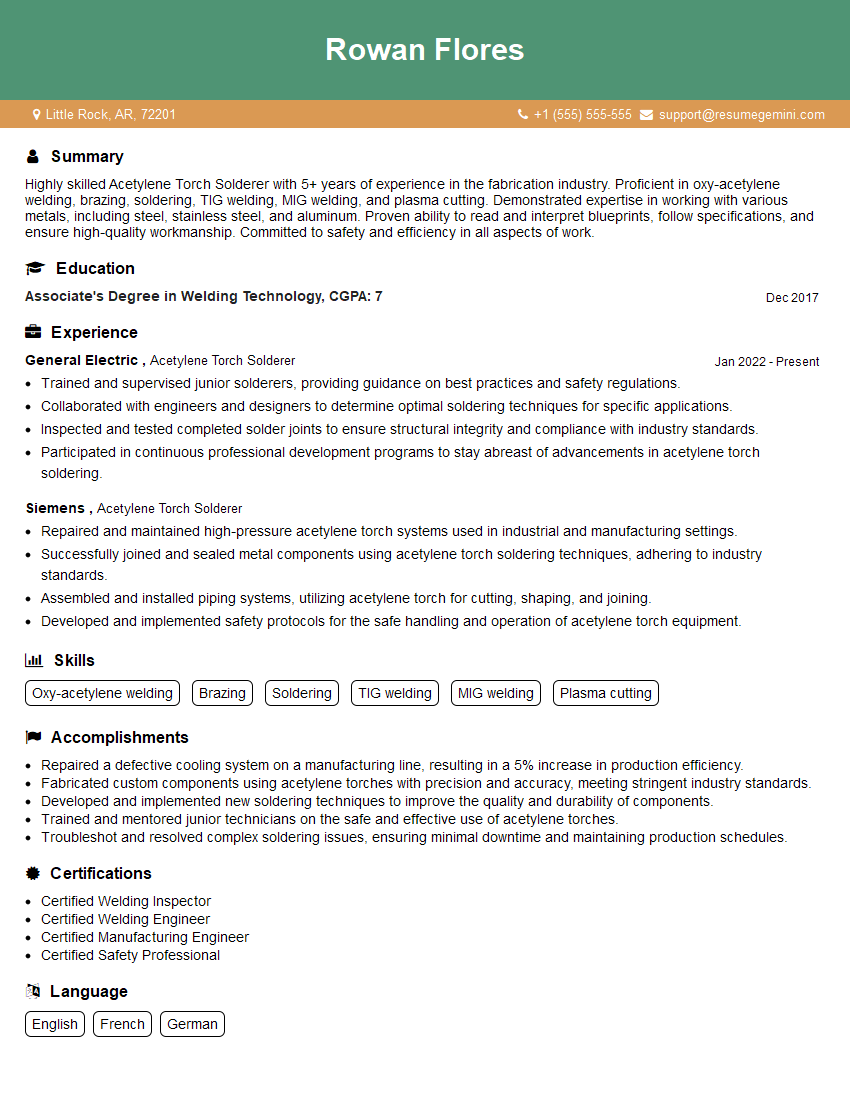

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Torch Solderer

1. What is the purpose of flux in soldering?

Flux is used in soldering to clean and prepare the metal surfaces to be joined. It removes oxides and impurities, allowing the solder to flow smoothly and create a strong bond.

- Removes oxides and impurities

- Prepares metal surfaces for bonding

- Ensures smooth solder flow

2. What are the different types of solder alloys used in acetylene torch soldering?

Soft Solders

- Tin-lead alloys (60/40, 50/50)

- Tin-antimony alloys

Hard Solders

- Silver alloys (e.g., 50% silver, 45% copper, 5% zinc)

- Copper-zinc alloys (e.g., 50% copper, 50% zinc)

3. How do you determine the appropriate solder temperature for a given task?

The appropriate solder temperature depends on the type of solder alloy and the materials being joined. A higher temperature is required for hard solders and thicker metals.

- Consider solder alloy type

- Assess material thickness

- Reference technical data sheets or industry standards

4. What factors affect the strength of a soldered joint?

- Joint design (e.g., overlap, butt joint)

- Solder alloy composition

- Surface preparation

- Proper heating technique

- Flux selection

5. Describe the safety precautions that must be taken when using an acetylene torch for soldering.

- Wear appropriate protective gear (gloves, goggles, apron)

- Ensure proper ventilation

- Check gas hoses and connections regularly

- Handle torch with care, avoiding direct exposure to flame

- Extinguish flame properly and allow torch to cool before storage

6. What are some common defects that can occur in soldered joints and how can they be prevented?

Cold Joints

- Cause: Insufficient heat

- Prevention: Proper heating and melting of solder

Solder Bridges

- Cause: Excess solder

- Prevention: Apply controlled amount of solder

Solder Balls

- Cause: Excessive heat

- Prevention: Use appropriate heat setting and keep torch moving

7. What is the difference between soldering and brazing?

- Soldering: Joining metals with a lower melting point solder alloy, below 450°C (842°F)

- Brazing: Joining metals with a higher melting point brazing alloy, above 450°C (842°F)

8. How do you troubleshoot a clogged solder tip?

- Check for blockages in the solder wire

- Clean tip with solder wick or abrasive pad

- If cleaning does not resolve issue, replace solder tip

9. What maintenance procedures are necessary for an acetylene torch system?

- Inspect and clean gas hoses and regulators

- Check and replace worn or damaged torch tips

- Lubricate torch handle and moving parts

- Store torch in a dry, clean environment

10. What is your experience with soldering complex or challenging assemblies?

Provide specific examples of projects or situations where you have successfully soldered complex or challenging assemblies. Highlight any special techniques or equipment used.

- Describe projects or situations involving complex assemblies

- Mention special techniques or equipment used

- Explain how these techniques or equipment helped overcome challenges

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Torch Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Torch Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Acetylene torch solderers perform a variety of tasks in the metal fabrication industry. Their key responsibilities include:

1. Set up and operate acetylene welding or cutting equipment

Solderers must be able to safely set up and operate acetylene welding or cutting equipment. This includes connecting the equipment to the gas supply, adjusting the flame, and testing the equipment to ensure it is working properly.

2. Solder metal components together

Solderers use acetylene torches to solder metal components together. This involves heating the metal to a high temperature and then applying solder to the joint. The solder melts and flows into the joint, creating a strong bond between the two pieces of metal.

3. Cut metal using an acetylene torch

Solderers also use acetylene torches to cut metal. This involves heating the metal to a high temperature and then using a stream of oxygen to cut through the metal.

4. Inspect and test welds and cuts

Solderers must inspect and test welds and cuts to ensure they are of good quality. This involves visually inspecting the welds and cuts, as well as using nondestructive testing methods to check for any defects.

Interview Tips

To ace an interview for an acetylene torch solderer position, candidates should prepare by:

1. Researching the company and the position

Candidates should research the company and the position to learn about the company’s culture and the specific requirements of the job. This will help them to tailor their answers to the interviewer’s questions and demonstrate their interest in the position.

2. Practicing their answers to common interview questions

Candidates should practice their answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” This will help them to feel more confident and prepared during the interview.

3. Bringing a portfolio of their work

Candidates who have a portfolio of their work can bring it to the interview to show the interviewer their skills and experience. This is a great way to demonstrate their abilities and make a lasting impression.

4. Asking thoughtful questions

Candidates should ask thoughtful questions at the end of the interview. This shows the interviewer that they are engaged and interested in the position. It also gives them an opportunity to learn more about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acetylene Torch Solderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!