Are you gearing up for an interview for a Acid Pump Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Acid Pump Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

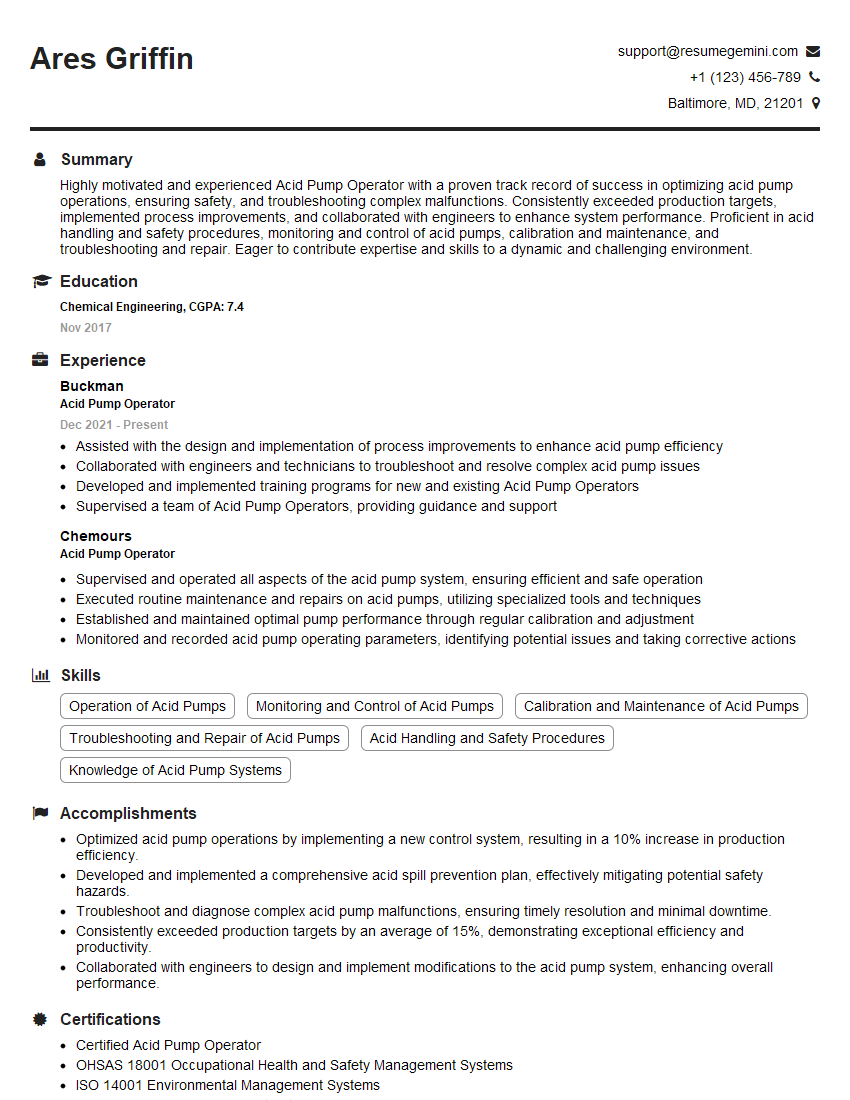

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acid Pump Operator

1. Explain the role and responsibilities of an Acid Pump Operator.

As an Acid Pump Operator, my key responsibilities revolve around the safe and efficient operation of pumps that transfer and handle various types of acid.

- Monitoring and controlling pumps to ensure optimal acid flow rates and pressures.

- Maintaining and inspecting pumps, including regular lubrication, gasket replacement, and troubleshooting.

- Adhering to strict safety protocols for handling hazardous chemicals, including wearing appropriate protective gear.

- Responding promptly to emergencies and spills, implementing containment and cleanup measures.

- Collaborating with maintenance teams to schedule and execute repairs and upgrades.

2. How do you ensure the safe handling of acids during your operations?

PPE and Safety Protocols

- Donning proper protective gear, including acid-resistant gloves, aprons, face shields, and respirators.

- Following established safety protocols for handling acids, including proper disposal methods.

- Maintaining a clean and organized work area to minimize the risk of spills or accidents.

Hazard Assessment and Control

- Identifying potential hazards associated with acid handling, such as leaks, spills, or chemical reactions.

- Implementing control measures to mitigate these hazards, such as using containment systems, emergency showers, and eyewash stations.

- Conducting regular safety inspections to assess potential risks and address any concerns promptly.

3. Describe your experience in troubleshooting and resolving common problems with acid pumps.

Throughout my tenure as an Acid Pump Operator, I have encountered and resolved various common pump issues:

- Pump cavitation: Identifying and addressing cavitation issues by adjusting pump speeds, optimizing fluid flow, or replacing damaged impellers.

- Seal failures: Diagnosing and repairing seal failures by replacing worn or damaged seals, tightening bolts, or adjusting gland packing.

- Clogged pumps: Troubleshooting and clearing clogged pumps by using backwashing techniques, removing debris from suction lines, or inspecting filters.

- Excessive vibration: Analyzing vibration causes and implementing solutions such as balancing impellers, tightening loose components, or replacing bearings.

- Pump inefficiency: Identifying factors contributing to pump inefficiency, such as worn components, misaligned shafts, or improper pump selection.

4. How do you prioritize your tasks in a fast-paced environment where multiple pumps require attention?

In a fast-paced environment, I prioritize my tasks based on the following criteria:

- Safety: Prioritizing any tasks that pose immediate safety concerns, such as handling acid leaks or spills.

- Critical operations: Focusing on tasks related to maintaining essential acid flow rates for critical production processes.

- Equipment health: Attending to pumps that exhibit signs of potential mechanical issues or impending breakdowns.

- Maintenance schedule: Completing scheduled maintenance tasks to prevent future problems and ensure optimal pump performance.

- Efficiency: Optimizing the operation of pumps to minimize downtime and maximize productivity.

5. How do you maintain accurate records and documentation related to pump operations?

I maintain accurate records and documentation through the following practices:

- Recording pump readings, including pressure, flow rates, and temperatures, regularly.

- Documenting maintenance activities, such as inspections, repairs, and replacements.

- Keeping a log of any incidents or emergencies related to acid handling.

- Using computerized systems or spreadsheets to organize and track data efficiently.

- Adhering to established recordkeeping procedures and ensuring the accuracy and integrity of all documentation.

6. Explain the importance of calibration and maintenance for acid pumps.

Calibration and maintenance of acid pumps are crucial for several reasons:

Calibration

- Accuracy: Ensures accurate measurements of acid flow rates and pressures.

- Process Control: Enables precise control of chemical processes that rely on acid flow.

- Safety: Detects potential malfunctions or failures that could compromise safety.

Maintenance

- Reliability: Regular maintenance prevents breakdowns and ensures continuous pump operation.

- Efficiency: Proper maintenance optimizes pump performance and minimizes energy consumption.

- Longevity: Extends the lifespan of acid pumps and reduces replacement costs.

7. Describe your understanding of the different types of acid pumps and their applications.

I am familiar with the following types of acid pumps and their applications:

Centrifugal Pumps

- Applications: Handling a wide range of acids, including hydrochloric acid, sulfuric acid, and nitric acid.

- Characteristics: High flow rates, low pressures, and self-priming capabilities.

Diaphragm Pumps

- Applications: Transferring corrosive acids with suspended solids or particles.

- Characteristics: Positive displacement, low flow rates, and high pressures.

Peristaltic Pumps

- Applications: Handling highly corrosive or abrasive acids.

- Characteristics: Gentle pumping action, low shear forces, and self-priming capabilities.

8. How do you stay up-to-date with advancements in acid pump technology?

To stay current with advancements in acid pump technology, I engage in the following activities:

- Attending industry conferences and seminars.

- Reading trade publications and technical journals.

- Participating in online forums and discussions.

- Consult with manufacturers and suppliers about new products and technologies.

- Undergoing training programs offered by equipment manufacturers.

9. Explain the importance of teamwork and communication in your role as an Acid Pump Operator.

Teamwork and communication are essential in my role for several reasons:

- Coordination: Collaborating with colleagues to ensure smooth operation and maintenance of acid pumping systems.

- Safety: Communicating potential hazards and emergency procedures to team members.

- Problem-solving: Working together to troubleshoot and resolve issues that arise during pump operations.

- Training: Sharing knowledge and expertise with team members to enhance overall performance.

- Continuous improvement: Communicating ideas and suggestions for process optimization and efficiency enhancements.

10. Describe a time when you faced a challenging situation while operating acid pumps and how you overcame it.

In a previous role, I encountered a critical pump failure during a crucial production process. The pump was transferring highly corrosive sulfuric acid, and its sudden failure posed a significant safety hazard.

- Immediate Response: I swiftly isolated the pump and initiated emergency shutdown procedures.

- Hazard Control: I deployed containment measures to prevent the spread of acid and evacuated the immediate area.

- Troubleshooting and Analysis: I conducted a thorough inspection of the pump and identified a broken impeller.

- Communication and Coordination: I communicated the situation to my supervisor and maintenance team, coordinating a plan for repair.

- Temporary Solution: To maintain critical production, I utilized a backup pump to ensure the continued flow of acid.

- Permanent Repair: The maintenance team replaced the impeller, and I oversaw the reinstallation and restart of the pump.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acid Pump Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acid Pump Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Acid Pump Operator, you will be responsible for operating and maintaining pumps that transfer acids and other corrosive liquids. This includes:

1. Monitoring and controlling pumps

You will be responsible for monitoring and controlling the operation of pumps, ensuring that they are running safely and efficiently. This includes checking fluid levels, pressures, and temperatures, and making adjustments as needed.

- Monitoring pump performance

- Adjusting pump settings

- Troubleshooting pump problems

2. Maintaining pumps

You will be responsible for maintaining the pumps in good working order, which includes performing regular inspections and preventive maintenance tasks. This may include replacing worn parts, lubricating moving parts, and cleaning the pumps.

- Lubricating pumps

- Replacing worn parts

- Cleaning pumps

3. Handling acids and other corrosive liquids

You will be responsible for handling acids and other corrosive liquids in a safe and responsible manner. This includes understanding the hazards of the chemicals, wearing appropriate personal protective equipment, and following proper handling procedures.

- Understanding the hazards of acids and other corrosive liquids

- Wearing appropriate personal protective equipment

- Following proper handling procedures

4. Working in a team environment

You will be working in a team environment, so you will need to be able to work well with others and communicate effectively. You will also need to be able to follow instructions and work independently.

- Working well with others

- Communicating effectively

- Following instructions

Interview Tips

Preparing for an interview can be nerve-wracking, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the position you’re interviewing for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience.

- Visit the company’s website

- Read about the company’s products or services

- Learn about the company’s culture and values

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare an elevator pitch

- Practice answering common interview questions

- Get feedback from a friend or family member

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure your shoes are clean and polished.

- Dress professionally

- Make sure your clothes are clean and pressed

- Polish your shoes

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer and let them know. It’s also a good idea to give yourself plenty of time to get to the interview location so that you’re not stressed or rushed.

- Be on time

- Give yourself plenty of time to get to the interview location

- Call the interviewer if you’re running late

5. Be confident

Confidence is key in an interview. Believe in yourself and your abilities, and don’t be afraid to show it. Make eye contact with the interviewer, speak clearly and confidently, and answer questions honestly and thoughtfully.

- Believe in yourself and your abilities

- Make eye contact with the interviewer

- Speak clearly and confidently

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Acid Pump Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.