Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Acid Retort Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Acid Retort Operator so you can tailor your answers to impress potential employers.

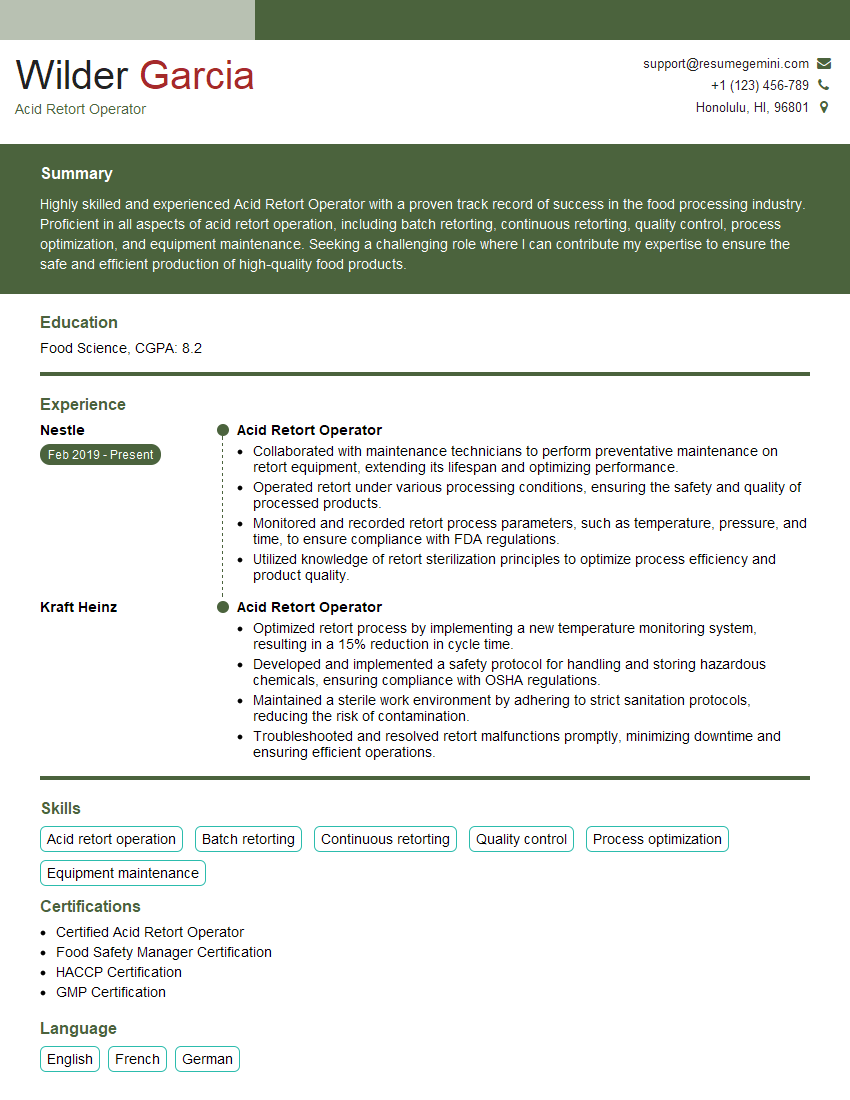

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acid Retort Operator

1. Explain the key responsibilities of an Acid Retort Operator?

As an Acid Retort Operator, I am responsible for:

- Retorting raw materials with sulfuric acid to treat and extract specified elements

- Maintaining and testing the retorting equipment to ensure optimal performance

- Monitoring the retorting process, collecting samples, and analyzing data to ensure product quality

- Adhering to safety protocols and environmental regulations to ensure the safety of all personnel and the environment

- Inspecting materials and components to ensure they meet specifications

- Participating in the maintenance and repairs of retorting equipment as needed

- Following established operating procedures and reporting any deviations promptly

- Maintaining a clean and organized work area

2. Describe the safety precautions and protocols involved in operating an Acid Retort?

General Safety Precautions

- Wear appropriate personal protective equipment (PPE), including acid-resistant clothing, gloves, and respiratory protection

- Understand and follow all safety procedures and protocols

- Avoid contact with acids, fumes, and other hazardous materials

- Never enter a retort chamber without proper authorization and safety precautions

Specific Operating Protocols

- Ensure that all equipment is properly grounded and electrically isolated

- Check all valves and connections for leaks before operating the retort

- Slowly and carefully raise the temperature and pressure inside the retort to avoid sudden pressure surges

- Monitor the pressure, temperature, and other parameters throughout the process

- Handle and dispose of hazardous materials according to established procedures

3. Explain the principles of retorting and how they are applied in the acid retorting process?

Retorting involves treating raw materials with sulfuric acid under high temperature and pressure conditions to extract specific elements or compounds. In the acid retorting process, the raw materials are placed in a retort vessel, and concentrated sulfuric acid is added. The vessel is then sealed, and the temperature and pressure are gradually increased. As the temperature rises, the acid reacts with the raw materials, breaking down their molecular structure and releasing the desired elements or compounds. The resulting vapors are then condensed and collected.

4. How do you troubleshoot and resolve common issues encountered in Acid Retort Operations?

Common issues in Acid Retort Operations include:

- Equipment malfunction: Check electrical connections, inspect components for wear or damage, and consult maintenance manuals.

- Leaks: Tighten connections, replace gaskets or seals, and inspect equipment for structural damage.

- Pressure or temperature deviations: Adjust valves, check controllers, and monitor pressure and temperature gauges.

- Insufficient product yield: Analyze raw materials, check retorting parameters, and optimize the process conditions.

- Corrosion or erosion: Inspect equipment for signs of damage, replace affected components, and apply protective coatings.

5. How do you ensure the quality of the final products obtained through Acid Retorting?

To ensure product quality, I follow these steps:

- Raw material inspection: Verify that raw materials meet specifications.

- Process monitoring: Regularly check pressure, temperature, and other parameters during retorting.

- Sample collection and analysis: Collect samples at various stages and analyze them for purity, concentration, and other quality attributes.

- Adherence to SOPs: Strictly follow established standard operating procedures.

- Equipment calibration and maintenance: Ensure that all equipment is calibrated and maintained according to manufacturer’s recommendations.

6. What are the environmental considerations and waste management practices in Acid Retort Operations?

Environmental considerations include:

- Acid neutralization: Neutralizing spent acid before disposal to minimize environmental impact.

- Fume and gas control: Using scrubbers and other systems to minimize the release of hazardous fumes and gases.

- Wastewater treatment: Treating wastewater generated from retorting processes to remove contaminants.

- Solid waste disposal: Safely disposing of solid waste generated from retorting operations, such as spent materials and contaminated equipment.

7. Describe your experience in working with hazardous materials in an industrial setting?

In my previous role as an Acid Retort Operator at [Company Name], I was responsible for handling hazardous materials, including sulfuric acid, hydrochloric acid, and nitric acid. I received comprehensive training on the safe handling, storage, and disposal of these materials. I am familiar with the Material Safety Data Sheets (MSDSs) for these chemicals and understand the potential hazards associated with them. I have also undergone regular medical surveillance to ensure my health and safety.

8. How do you prioritize tasks and manage your time effectively in a fast-paced Acid Retort Operation environment?

I prioritize tasks based on their importance and urgency. I use a to-do list to keep track of my responsibilities and set deadlines for each task. I break down complex tasks into smaller, more manageable steps. I also delegate tasks to other team members when appropriate. I am comfortable working independently and as part of a team. I am also able to adapt quickly to changing priorities and deadlines.

9. Describe your understanding of the role of automation and technology in modern Acid Retort Operations?

Automation and technology play a vital role in modern Acid Retort Operations by:

- Improving efficiency: Automated systems can perform tasks faster and more accurately than manual labor.

- Enhancing safety: Automation can reduce the risk of accidents and injuries to workers.

- Ensuring product quality: Automated systems can monitor and control process parameters more precisely than manual operations.

- Reducing operating costs: Automation can eliminate the need for additional staff and overtime pay.

10. How do you stay up-to-date with the latest advancements and best practices in Acid Retort Operations?

I stay up-to-date with the latest advancements and best practices in Acid Retort Operations by:

- Attending industry conferences and workshops

- Reading trade journals and publications

- Participating in online forums and discussion groups

- Consulting with experts in the field

- Taking continuing education courses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acid Retort Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acid Retort Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Acid Retort Operators are responsible for operating and maintaining acid retorts, which are used to sterilize food and beverage products. They ensure that the retorts are operating safely and efficiently, and that the products are sterilized to the correct specifications. Key job responsibilities include:

1. Operating and Maintaining Retorts

Operators are responsible for the safe and efficient operation of acid retorts. This includes monitoring retort temperatures and pressures, ensuring that the retorts are properly sealed, and maintaining the retorts in good working order. They also perform regular maintenance on the retorts, such as cleaning and lubricating the equipment.

2. Loading and Unloading Retorts

Operators load and unload retorts with food and beverage products. They must follow specific procedures to ensure that the products are properly loaded and unloaded, and that the retorts are sealed properly.

3. Monitoring Sterilization Process

Operators monitor the sterilization process to ensure that the products are sterilized to the correct specifications. They record retort temperatures and pressures, and make adjustments as needed to ensure that the products are sterilized properly.

4. Maintaining Sanitation

Operators maintain sanitation in the retort area by cleaning and disinfecting the equipment and work area. They also follow good manufacturing practices (GMPs) to ensure that the products are safe for consumption.

Interview Tips

To help you ace your interview for an Acid Retort Operator position, consider the following tips:

1. Research the Company and the Position

Familiarize yourself with the company’s website and social media pages to learn more about their culture, values, and products. Understand the specific responsibilities of the Acid Retort Operator role, as outlined in the job description.

2. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?”, and “What are your strengths and weaknesses?”. Relate your answers to the key responsibilities of the Acid Retort Operator position and emphasize your relevant skills and experience.

3. Highlight Your Safety and Quality Assurance Knowledge

Emphasize your understanding of safety protocols and quality assurance measures related to food and beverage sterilization. Discuss your experience with maintaining a clean and sanitary work environment and adhering to GMPs.

4. Showcase Your Attention to Detail and Problem-Solving Abilities

Highlight your ability to pay close attention to details and follow instructions precisely. Describe situations where you successfully identified and resolved problems related to retort operations or product quality.

5. Be Enthusiastic and Professional

Demonstrate your passion for the food and beverage industry and your commitment to producing high-quality products. Maintain a professional demeanor throughout the interview and be confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acid Retort Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!