Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Adzing and Boring Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

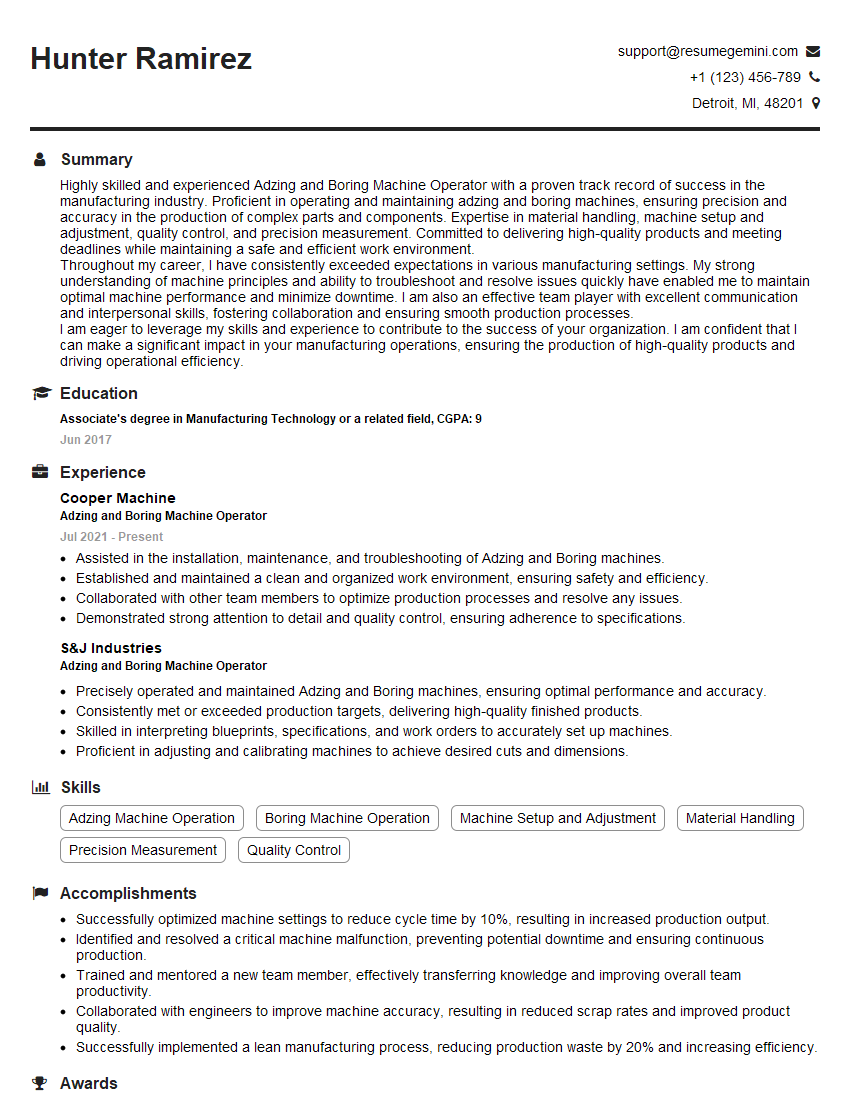

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Adzing and Boring Machine Operator

1. Describe the process of setting up an adzing and boring machine?

To set up an adzing and boring machine, I follow these steps:

- Secure the workpiece properly on the machine table using clamps or fixtures.

- Select and install the appropriate cutters for the desired operation, such as adzing or boring.

- Set the cutting depth and feed rate according to the material and desired finish.

- Calibrate the machine’s reference point and zero out the scales for accurate positioning.

- Run a test cut or perform a dry run to ensure proper operation before starting the actual cut.

2. How do you maintain and troubleshoot an adzing and boring machine?

Daily Maintenance:

- Clean the machine bed, table, and cutters to remove chips and debris.

- Lubricate moving parts as per the manufacturer’s instructions.

- Check the cutting edges of the cutters and replace or sharpen them as needed.

Troubleshooting:

- If the machine vibrates excessively, check for loose bolts or worn bearings.

- If the cuts are not clean or precise, inspect the cutters for damage or misalignment.

- If there is a loss of power or motor failure, follow the manufacturer’s guidelines for troubleshooting electrical issues.

3. What safety precautions should be taken when operating an adzing and boring machine?

To ensure safety, I adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including goggles, earplugs, and gloves.

- Keep the work area clean and free of obstacles to prevent slipping or tripping.

- Never place hands or fingers near moving parts, including the cutters and the workpiece.

- Use sharp cutters to avoid excessive force or strain when operating the machine.

- Follow the manufacturer’s instructions for safe machine operation and maintenance.

4. How do you determine the correct cutting parameters for different materials?

To determine optimal cutting parameters for various materials, I consider the following factors:

- Material hardness and toughness: Harder materials require slower feed rates to prevent tool damage.

- Material thickness and depth of cut: Thicker materials or deeper cuts require lower feed rates.

- Type of cutting operation (adzing or boring): Boring typically requires slower feed rates than adzing.

- Cutter type and geometry: Different cutter shapes and sizes affect cutting performance.

- Consult manufacturer’s recommendations and industry standards for specific materials and machine capabilities.

5. What types of materials can be processed on an adzing and boring machine?

An adzing and boring machine is versatile and can process a wide range of materials, including:

- Wood and wood composites (e.g., plywood, MDF, hardwoods)

- Plastics (e.g., acrylic, PVC, polyethylene)

- Soft metals (e.g., aluminum, copper, brass)

- Certain types of laminates and veneers

- Composites and fiber-reinforced materials

6. How do you measure and ensure the accuracy of the workpiece after machining?

To ensure workpiece accuracy after machining, I follow these steps:

- Use precision measuring tools such as calipers, micrometers, or coordinate measuring machines (CMMs).

- Measure critical dimensions and compare them to the desired specifications or drawings.

- Make necessary adjustments to the machine setup or cutting parameters if deviations are detected.

- Double-check measurements to minimize errors and ensure accuracy.

- Keep accurate records of measurements and adjustments for future reference.

7. How do you handle complex or intricate machining operations on an adzing and boring machine?

For complex machining operations, I utilize the following techniques:

- Break down the operation into smaller, manageable steps.

- Use fixtures or jigs to ensure precision and repeatability.

- Program the machine using CAD/CAM software for automated precision cutting.

- Take multiple passes with different cutting depths to achieve the desired shape or profile.

- Collaborate with engineers or designers to refine the design and optimize the machining process.

8. How do you stay updated with the latest advancements in adzing and boring machine technology?

To stay current with advancements in technology, I:

- Attend industry conferences and trade shows.

- Read technical journals and industry publications.

- Participate in online forums and discussion groups.

- Seek training and certification opportunities provided by equipment manufacturers.

- Stay informed about new cutting tools, software, and automation technologies.

9. Describe a situation where you had to troubleshoot a challenging machining problem on an adzing and boring machine.

During a recent project, I encountered an issue where the machine was producing inconsistent cuts. I followed a systematic troubleshooting process:

- Inspected the cutters for wear and replaced them as needed.

- Checked the machine setup and adjusted the feed rate and cutting depth.

- Examined the workpiece material for any inconsistencies or defects.

- Consulted the manufacturer’s manual for troubleshooting guidance.

- Ultimately identified the issue as a misalignment in the machine’s spindle.

10. How do you maintain a positive and productive work environment with your colleagues?

To foster a positive and productive work environment, I:

- Communicate openly and respectfully with colleagues.

- Offer assistance and support whenever possible.

- Respect diversity and different perspectives.

- Maintain a clean and organized workspace.

- Recognize and appreciate others’ contributions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Adzing and Boring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Adzing and Boring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Adzing and Boring Machine Operators are responsible for operating and maintaining adzing and boring machines to create holes, grooves, and other shapes in wood or metal workpieces. These operators must have a strong understanding of the machine’s capabilities and limitations, as well as the ability to read and interpret blueprints and technical drawings.

1. Machine Operation

Operators are responsible for setting up, operating, and maintaining adzing and boring machines. This includes adjusting the machine’s settings, loading and unloading workpieces, and monitoring the machine’s operation to ensure that it is running smoothly.

- Set up and operate adzing and boring machines to cut, shape, and drill holes in wood or metal workpieces.

- Secure workpieces to the machine table using clamps or fixtures.

- Monitor the machine’s operation to ensure that it is running smoothly and that the workpiece is being cut or drilled accurately.

2. Machine Maintenance

In addition to operating the machine, operators are also responsible for maintaining the machine in good working condition. This includes cleaning, lubricating, and adjusting the machine as needed.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for wear and tear, and replace or repair any worn or damaged parts.

- Adjust the machine’s settings as needed to ensure that it is operating properly.

3. Blueprint Reading

Operators must be able to read and interpret blueprints and technical drawings in order to set up and operate the machine correctly. This includes understanding the dimensions of the workpiece, the location of the holes or grooves to be cut, and the type of cutting tool to be used.

- Read and interpret blueprints and technical drawings to determine the dimensions and specifications of the workpiece.

- Identify the type of cutting tool and the appropriate settings for the machine.

- Set up the machine according to the specifications in the blueprint.

4. Safety

Adzing and boring machines can be dangerous if they are not operated properly. Operators must be aware of the hazards associated with the machine and must take precautions to avoid injury.

- Wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris.

- Follow all safety procedures and guidelines.

Interview Tips

Preparing for an interview can be nerve-wracking, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview for an Adzing and Boring Machine Operator position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read news articles and press releases about the company.

- Talk to people who work at the company, if possible.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Practice your answers with a friend or family member.

- Time yourself to make sure that your answers are concise.

3. Be prepared to talk about your experience and skills

During your interview, the interviewer will want to know about your experience and skills. Be prepared to talk about your experience operating adzing and boring machines, as well as any other relevant experience that you have.

- Highlight your experience in operating adzing and boring machines.

- Discuss your experience in reading and interpreting blueprints and technical drawings.

- Mention any other relevant experience that you have, such as experience in machine maintenance or safety.

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer. Show the interviewer that you are interested in the position and that you are eager to learn more about the company.

- Dress appropriately for the interview.

- Arrive on time for your interview.

- Be polite and respectful to the interviewer.

- Show the interviewer that you are interested in the position.

- Be enthusiastic about the company and the opportunity.

Next Step:

Now that you’re armed with the knowledge of Adzing and Boring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Adzing and Boring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini