Feeling lost in a sea of interview questions? Landed that dream interview for Aerosol Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aerosol Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

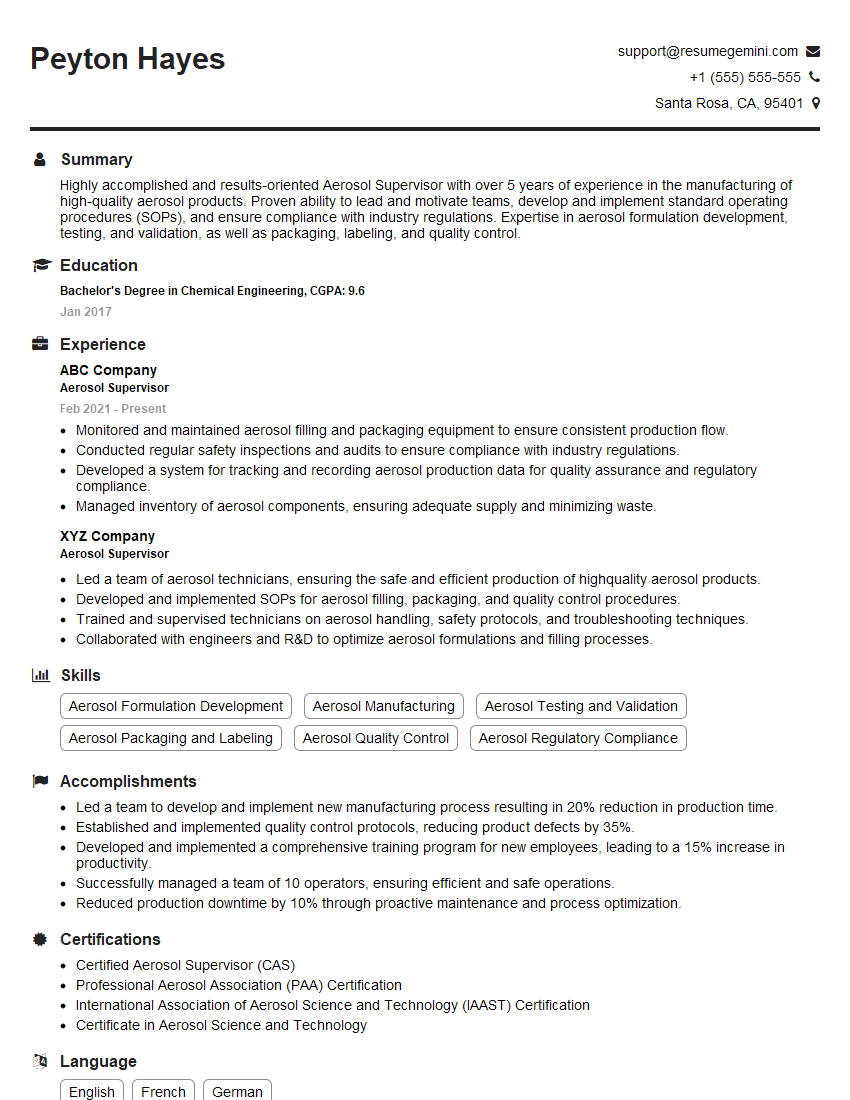

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aerosol Supervisor

1. How do you ensure the quality of aerosol products during production?

To maintain the quality of our aerosol products during production, we implement several comprehensive measures:

- Raw Material Inspection: We thoroughly inspect all incoming raw materials against established specifications to ensure they meet our quality standards.

- In-Process Monitoring: Throughout the production process, we conduct regular inspections and tests to monitor critical parameters such as pressure, fill weight, and spray pattern.

- Quality Control Testing: Before releasing products for distribution, we perform rigorous quality control testing to verify compliance with our specifications and regulatory requirements.

- Continuous Improvement: We regularly review our quality processes and seek opportunities for improvement to enhance product quality and consistency.

2. Explain the principles and techniques used in aerosol filling.

Filling Methods

- Pressure Filling: Uses compressed gas to force the product into the container.

- Vacuum Filling: Creates a vacuum in the container and draws the product in.

- Cold Filling: Cools the product to reduce its volume, allowing for more product to be filled.

Propellant Selection and Blending

- Propellant Properties: Flammability, compatibility with product, pressure.

- Propellant Blending: Mixing different propellants to achieve desired pressure and spray characteristics.

Fill Accuracy and Control

- Fill Weight Measurement: Ensuring precise product volume in each container.

- Crimping and Sealing: Securely sealing the container to maintain pressure and prevent leakage.

3. Describe the packaging and storage requirements for aerosol products.

Aerosol products require specific packaging and storage conditions to ensure safety and preserve their quality.

- Containers: Made of materials compatible with the product and propellant.

- Labeling: Clear and accurate labeling with product information, safety warnings, and storage instructions.

- Storage Conditions: Cool, dry, well-ventilated areas away from heat sources and direct sunlight.

- Temperature Control: Maintaining specific temperature ranges to prevent pressure buildup and product degradation.

- Transportation: Complying with regulations governing the transportation of flammable and pressurized products.

4. Explain the safety protocols for handling and operating aerosol production equipment.

Ensuring the safety of our employees and the workplace is paramount in aerosol production.

- Machine Guards and Safety Devices: Ensuring equipment is properly guarded and safety mechanisms are functional.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE such as respirators, gloves, and eye protection.

- Training and Certification: Training employees on safe operating procedures and emergency response protocols.

- Flammable Gas Handling: Following strict procedures for handling and storing flammable propellants.

- Emergency Response Plans: Establishing clear and comprehensive emergency response plans for potential incidents.

5. Describe the maintenance and calibration procedures for aerosol filling equipment.

Regular maintenance and calibration are essential to ensure the accuracy, reliability, and safety of aerosol filling equipment.

- Scheduled Maintenance: Following a preventative maintenance schedule to identify and address potential issues early on.

- Calibration: Calibrating equipment regularly using certified standards to ensure accurate readings.

- Cleaning and Inspection: Thoroughly cleaning and inspecting equipment to remove contaminants and identify any defects.

- Lubrication: Lubricating moving parts to minimize friction and wear.

- Record Keeping: Maintaining detailed records of maintenance and calibration activities for traceability and compliance.

6. How do you manage and train a team of aerosol production operators?

Team Management

- Clear Communication: Establishing open and effective communication channels.

- Delegation and Empowerment: Empowering team members and assigning responsibilities.

- Performance Monitoring: Regularly assessing and providing feedback on performance.

Training and Development

- Initial Training: Comprehensive training on equipment operation, safety protocols, and quality standards.

- On-the-Job Training: Providing opportunities for hands-on experience and skill development.

- Continuous Education: Encouraging ongoing learning and professional growth.

7. Discuss the environmental regulations and industry best practices related to aerosol production.

We adhere to all applicable environmental regulations and industry best practices to minimize our environmental impact.

- Waste Management: Proper disposal of hazardous waste generated during production.

- Propellant Emissions: Implementing measures to reduce the release of volatile organic compounds (VOCs).

- Energy Efficiency: Optimizing processes and equipment to minimize energy consumption.

- Employee Safety: Establishing robust safety protocols to protect our employees and the environment.

8. How do you monitor and control the production costs of aerosol products?

- Raw Material Costs: Negotiating competitive pricing and optimizing inventory levels.

- Production Efficiency: Optimizing production processes to minimize waste and increase output.

- Labor Costs: Effective workforce management and training to enhance productivity.

- Overhead Expenses: Monitoring and controlling indirect costs such as utilities and maintenance.

- Cost Forecasting: Regularly analyzing data to forecast future costs and identify potential savings.

9. Explain the role of quality assurance in aerosol production.

- Product Testing: Conducting rigorous product testing to ensure compliance with specifications and safety standards.

- Process Validation: Validating production processes to ensure consistent product quality.

- Corrective Action: Identifying and implementing corrective actions to address quality issues.

- Continuous Improvement: Embracing a culture of continuous improvement to enhance quality standards.

- Customer Satisfaction: Monitoring customer feedback and resolving any quality-related concerns promptly.

10. How do you stay updated with the latest advancements and technologies in the aerosol industry?

- Industry Publications: Regularly reading industry journals and publications to stay informed about technological developments.

- Conferences and Trade Shows: Attending industry events to network with experts and learn about new advancements.

- Research and Development: Conducting in-house research and collaborating with external partners to explore innovative technologies.

- Supplier Partnerships: Maintaining strong relationships with suppliers to gain insights into emerging trends and solutions.

- Continuing Education: Pursuing professional development opportunities to enhance my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aerosol Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aerosol Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aerosol Supervisors play a crucial role in ensuring the efficient and safe operation of an aerosol manufacturing facility. Their primary responsibilities include:

1. Production Management

Supervising and monitoring all aspects of aerosol production, including planning, scheduling, and execution.

- Optimizing production processes to maximize efficiency and minimize waste.

- Ensuring adherence to quality standards, safety protocols, and regulatory compliance.

2. Team Leadership

Leading and motivating a team of production operators, ensuring their safety and well-being.

- Providing training and guidance to team members on proper operating procedures.

- Monitoring employee performance, providing feedback, and implementing corrective actions when necessary.

3. Quality Control

Ensuring the quality of aerosol products by implementing and maintaining quality control procedures.

- Inspecting raw materials and finished products for defects, contamination, and compliance with specifications.

- Implementing corrective actions to address any quality issues and prevent recurrence.

4. Maintenance and Troubleshooting

Maintaining and troubleshooting production equipment to ensure optimal performance and minimize downtime.

- Performing regular maintenance, calibrations, and repairs on equipment.

- Troubleshooting equipment malfunctions, identifying root causes, and implementing solutions.

Interview Tips

To ace an interview for an Aerosol Supervisor position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrating knowledge of the company’s background, products, and industry trends shows initiative and interest.

- Visit the company website and read industry news and reports.

- Network with professionals in the field to gain insights.

2. Highlight Relevant Experience and Skills

Focus on showcasing experience and skills that align with the key job responsibilities, such as production management, quality control, and team leadership.

- Quantify accomplishments whenever possible, using specific numbers and metrics.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

3. Emphasize Safety and Compliance

Aerosol production involves potential safety hazards. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience with OSHA regulations and industry best practices.

- Mention any safety initiatives you have implemented or participated in.

4. Prepare for Technical Questions

Expect technical questions related to aerosol production processes, equipment maintenance, and quality control procedures.

- Review industry literature and technical manuals to refresh your knowledge.

- Consider preparing questions of your own to show your engagement and interest.

5. Practice Behavioral Questions

Behavioral questions assess your problem-solving skills, teamwork abilities, and leadership style.

- Prepare examples of situations where you demonstrated these qualities.

- Practice answering questions using the STAR method to provide a clear and structured response.

Next Step:

Now that you’re armed with the knowledge of Aerosol Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Aerosol Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini