Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Agricultural Equipment Test Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Agricultural Equipment Test Engineer so you can tailor your answers to impress potential employers.

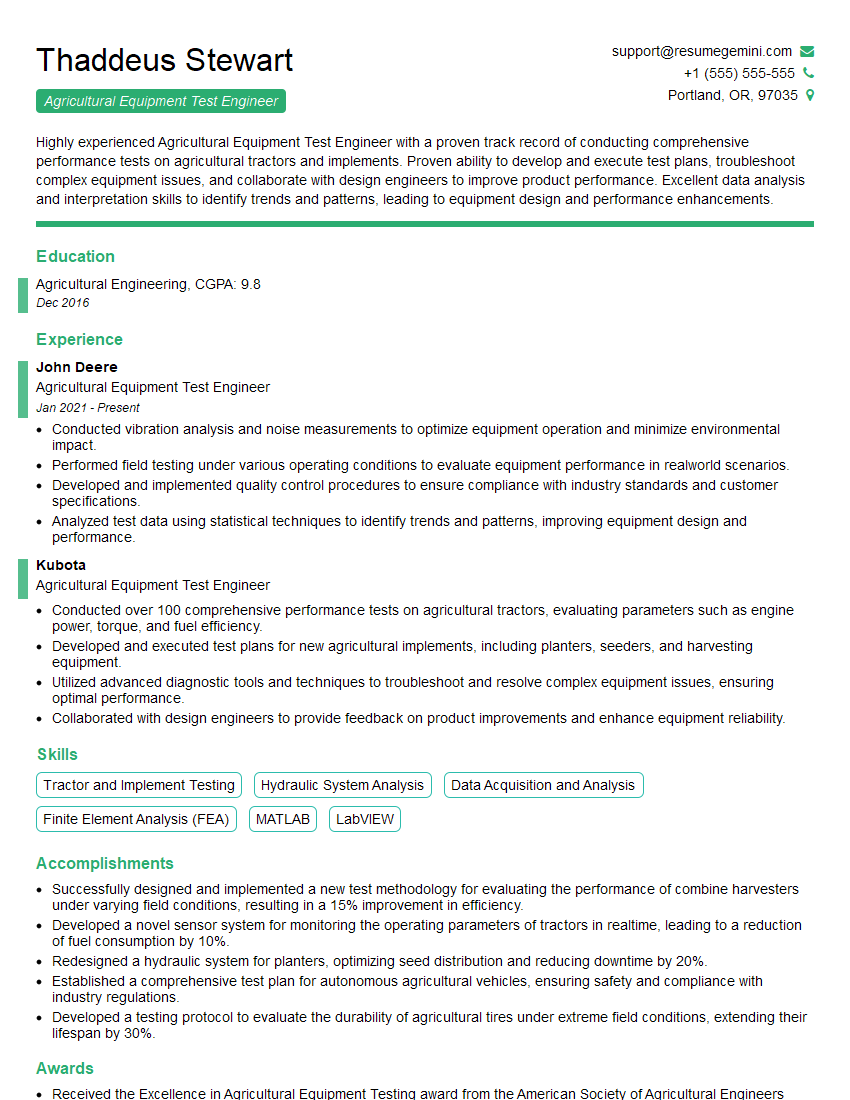

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Agricultural Equipment Test Engineer

1. Describe the process of testing an agricultural tractor’s hydraulic system?

The process of testing an agricultural tractor’s hydraulic system involves the following steps:

- Visual inspection: Checking for any leaks, loose connections, or damage to components.

- Pressure testing: Using a pressure gauge to measure the system’s pressure at various points and comparing it to specifications.

- Flow testing: Measuring the flow rate of the hydraulic fluid through the system using a flow meter.

- Temperature testing: Monitoring the temperature of the hydraulic fluid to ensure it remains within acceptable limits.

- Functional testing: Operating the tractor’s hydraulically powered implements to verify their proper function.

2. What are the key performance indicators (KPIs) for a combine harvester?

Harvest efficiency

- Percentage of crop harvested per unit of time

- Minimization of crop losses

Grain quality

- Percentage of intact kernels

- Moisture content of grain

- Freedom from impurities

Machine reliability

- Number of breakdowns per season

- Mean time between failures

- Cost of repairs and maintenance

3. Explain the principles of operation of a GPS-guided sprayer.

A GPS-guided sprayer uses a combination of GPS technology and electronic controls to automatically guide the sprayer boom and adjust the application rate based on the location in the field. The system typically consists of:

- GPS receiver: Mounted on the sprayer, receives signals from GPS satellites to determine its exact location.

- Control system: Processes the GPS data and calculates the required spray pattern and application rate.

- Boom control: Actuators adjust the position of the spray boom based on the control system’s commands.

- Variable-rate control: Adjusts the spray rate based on factors such as crop density, soil type, and yield potential.

4. Describe the safety precautions that must be taken when testing a self-propelled windrower.

- Ensure proper training: Only trained personnel should operate the windrower.

- Wear appropriate PPE: Hard hat, safety glasses, gloves, and hearing protection.

- Inspect the windrower before use: Check for any damage or loose components.

- Clear the test area: Remove any obstacles or debris that could pose a hazard.

- Have a spotter present: A second person should be present to observe the windrower’s operation and assist if needed.

- Be aware of surroundings: Pay attention to pedestrians, vehicles, and other potential hazards.

- Follow emergency procedures: Know the steps to take in case of an accident or equipment failure.

5. Explain the difference between a PTO shaft and a hydraulic motor.

- PTO shaft: A mechanical device that transmits power from the tractor’s engine to an implement.

- Hydraulic motor: A hydraulic device that converts hydraulic fluid pressure into mechanical energy.

Key differences:

- Power source: PTO shaft uses the tractor’s engine power, while a hydraulic motor uses hydraulic fluid pressure.

- Speed control: PTO shaft speed is directly related to the tractor’s engine speed, while a hydraulic motor’s speed can be controlled independently.

- Torque: PTO shafts can transmit higher torque than hydraulic motors.

- Efficiency: PTO shafts are generally more efficient than hydraulic motors.

6. Describe the process of calibrating a grain moisture sensor.

- Obtain reference samples: Collect a representative sample of the grain to be tested.

- Measure the moisture content: Use a laboratory-grade moisture meter to determine the actual moisture content of the samples.

- Enter the values into the sensor: Configure the moisture sensor to display readings that match the laboratory results.

- Verify the calibration: Test the sensor with additional samples to ensure accurate readings.

7. Explain the importance of data acquisition and analysis in agricultural equipment testing.

- Performance evaluation: Data analysis helps determine the efficiency, reliability, and overall performance of the equipment.

- Problem identification: Analysis can reveal potential issues or areas for improvement.

- Optimization: Data insights can guide adjustments and modifications to optimize equipment design and functionality.

- Safety improvements: Analysis can identify safety hazards and inform the development of mitigation strategies.

- Regulatory compliance: Data can be used to demonstrate compliance with industry standards and regulations.

8. Discuss the challenges involved in testing autonomous agricultural vehicles.

- Environmental factors: Unpredictable weather conditions, varying terrain, and obstacles.

- Sensor reliability: Ensuring the accuracy and reliability of sensors used for navigation, obstacle detection, and data collection.

- Safety concerns: Addressing public safety and potential risks associated with autonomous vehicles operating in agricultural environments.

- Data management: Handling and processing large volumes of data generated by autonomous vehicles.

- Regulatory framework: Evolving regulations and standards governing the use of autonomous vehicles in agriculture.

9. Describe the role of simulation in the development and testing of agricultural equipment.

- Virtual prototyping: Testing equipment designs in a simulated environment before building physical prototypes.

- Performance prediction: Simulating different operating conditions to predict equipment performance and identify potential issues.

- Failure analysis: Using simulation to analyze potential failure modes and design for reliability.

- Training and evaluation: Providing virtual training environments for operators and evaluating their skills.

- Optimization: Simulating equipment operations to identify areas for improvement and optimize design parameters.

10. Explain the principles of system integration testing for agricultural machinery.

- Functional testing: Verifying that each subsystem performs its intended function correctly.

- Interface testing: Ensuring proper communication and data exchange between subsystems.

- Performance testing: Evaluating the overall performance of the integrated system under various operating conditions.

- Safety testing: Verifying that the system meets safety requirements and operates without posing hazards.

- Regression testing: Re-testing previously tested functionality after system modifications to ensure stability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Agricultural Equipment Test Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Agricultural Equipment Test Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Agricultural Equipment Test Engineer, you will be responsible for various critical tasks that ensure the proper functioning and safety of agricultural machinery.

1. Equipment Testing and Evaluation

You will conduct rigorous tests on agricultural equipment to assess their performance, durability, and reliability.

- Design and execute test plans to evaluate equipment capabilities and identify areas for improvement.

- Operate equipment in field conditions to collect real-world data on performance and efficiency.

2. Data Analysis and Interpretation

You will analyze test data to identify trends, anomalies, and areas for optimization.

- Interpret test results using statistical and data analytics techniques to draw insights and conclusions.

- Use data to identify potential problems, recommend solutions, and improve equipment design.

3. Report Writing and Presentation

You will document test results, provide recommendations, and present findings to stakeholders.

- Generate comprehensive test reports that detail equipment performance, test conditions, and conclusions.

- Present test results to engineers, managers, and customers, effectively conveying findings and recommendations.

4. Collaboration and Teamwork

You will collaborate with cross-functional teams to ensure successful testing and equipment development.

- Work closely with engineers, designers, and technicians to provide insights and feedback on equipment design and performance.

- Participate in brainstorming sessions and contribute ideas for innovative solutions to improve agricultural equipment.

Interview Tips

To ace your interview for an Agricultural Equipment Test Engineer position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s products, services, and the latest advancements in agricultural equipment.

Research industry trends and challenges to show your understanding of the field and your ability to contribute to the company’s success.

2. Highlight Your Technical Skills

Emphasize your expertise in testing and evaluation methodologies, data analysis techniques, and equipment operation.

Quantify your accomplishments and provide specific examples of your contributions to previous projects.

3. Showcase Your Communication Skills

Present yourself as an effective communicator who can clearly articulate technical concepts to both technical and non-technical audiences.

Discuss your experience in writing test reports, presenting findings, and collaborating with cross-functional teams.

4. Prepare for Common Interview Questions

Review common interview questions for this role, such as:

- Describe your experience in testing agricultural equipment.

- How do you interpret and analyze test data?

- Can you provide an example of a successful test you conducted?

- How do you stay up-to-date with industry best practices in equipment testing?

5. Bring a Positive and Enthusiastic Attitude

Convey your passion for agricultural equipment and your eagerness to contribute to the industry’s advancement.

Show your enthusiasm for problem-solving, teamwork, and continuous learning.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Agricultural Equipment Test Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!