Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Bag Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

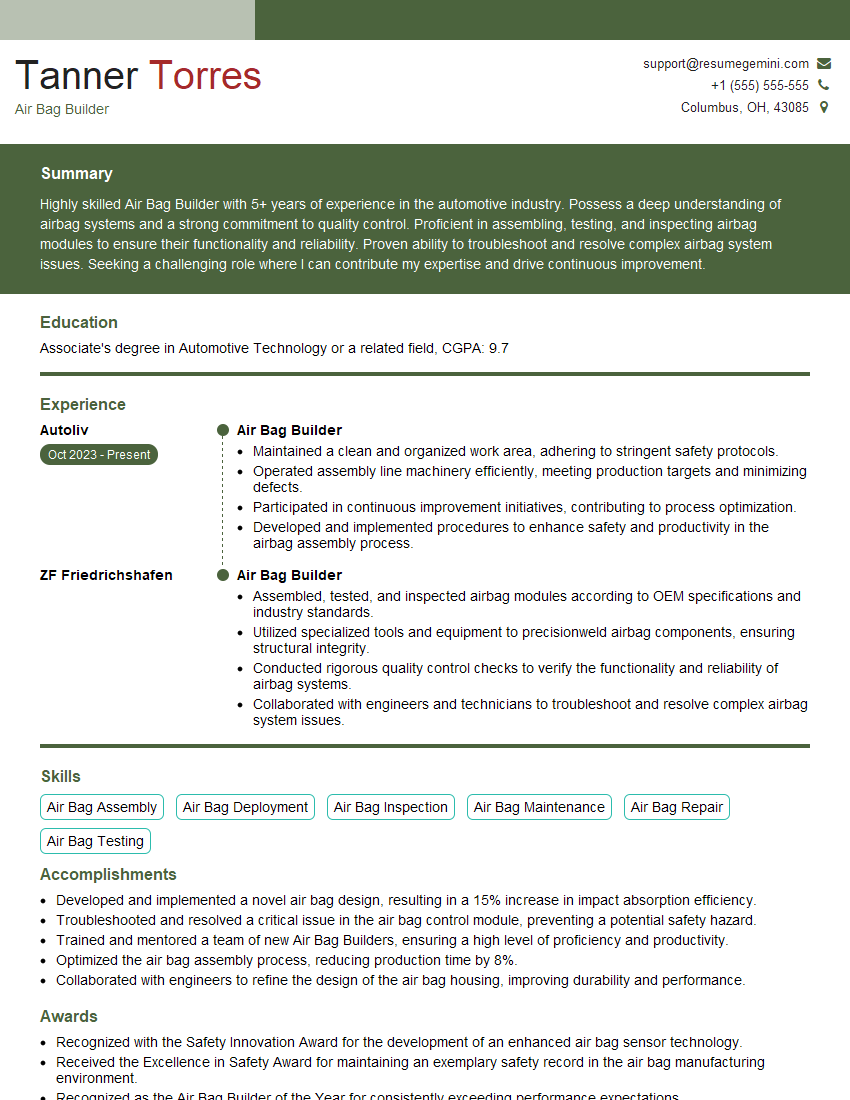

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Bag Builder

1. Describe the key steps involved in air bag manufacturing?

Sample Answer: The key steps involved in air bag manufacturing are:

- Fabric cutting: The fabric used for the air bag is cut into panels using a laser or die cutter.

- Sewing: The panels are sewn together to form the air bag shape.

- Inflation testing: The air bag is inflated with gas to test its performance and ensure it meets safety standards.

- Folding and packing: The air bag is folded and packed into a compact form for storage and shipping.

2. What are the different types of air bags used in vehicles?

Sample Answer: The different types of air bags used in vehicles include:

- Frontal airbags: These are located in the dashboard and deploy in the event of a frontal collision to protect the driver and front-seat passenger.

- Side airbags: These are located in the side panels of the vehicle and deploy in the event of a side-impact collision to protect the occupants from side impacts.

- Curtain airbags: These are located along the roof of the vehicle and deploy in the event of a rollover to protect the occupants from head injuries.

- Knee airbags: These are located below the dashboard and deploy in the event of a frontal collision to protect the driver’s knees and lower extremities.

3. What are the critical quality control measures in air bag production?

Sample Answer: Critical quality control measures in air bag production include:

- Material inspection: The fabric and other materials used in air bag production are inspected to ensure they meet specifications.

- Sewing inspection: The seams of the air bag are inspected to ensure they are sewn correctly and meet strength requirements.

- Inflation testing: Each air bag is inflated multiple times to test its performance and reliability.

- Functional testing: The air bag is tested to ensure that it deploys and inflates properly in the event of a collision.

4. What are the latest advancements in air bag technology?

Sample Answer: Recent advancements in air bag technology include:

- Multi-stage air bags: These air bags deploy in stages, providing different levels of protection depending on the severity of the collision.

- Adaptive air bags: These air bags use sensors to adjust their deployment based on the size and position of the occupant.

- Pedestrian air bags: These air bags are designed to deploy outside the vehicle in the event of a collision with a pedestrian, reducing the risk of injuries.

5. How do you stay up-to-date with the latest developments in air bag technology?

Sample Answer: I stay up-to-date with the latest developments in air bag technology by:

- Attending industry conferences and workshops.

- Reading technical journals and research papers.

- Participating in online forums and discussion groups.

- Collaborating with experts in the field.

6. What is your experience with using computer-aided design and manufacturing (CAD/CAM) systems in air bag production?

Sample Answer: I have extensive experience using CAD/CAM systems in air bag production. I am proficient in using software such as CATIA and SolidWorks to design and simulate air bag components. I have also used CAM software to generate CNC programs for manufacturing air bag parts.

7. How do you ensure that air bags meet safety regulations and standards?

Sample Answer: I ensure that air bags meet safety regulations and standards by:

- Following strict quality control procedures.

- Adhering to industry best practices.

- Collaborating with regulatory agencies.

- Conducting regular audits and inspections.

8. What are the common challenges faced in air bag manufacturing and how do you overcome them?

Sample Answer: Common challenges faced in air bag manufacturing include:

- Material defects: Material defects can compromise the performance and safety of air bags. I overcome this by implementing stringent quality control measures and working closely with suppliers to ensure that materials meet specifications.

- Manufacturing errors: Manufacturing errors can occur during the sewing, assembly, and inflation testing processes. I overcome this by providing training to operators and implementing automated inspection systems.

- Environmental factors: Environmental factors such as temperature and humidity can affect the performance of air bags. I overcome this by using temperature and humidity-controlled manufacturing environments.

9. How do you manage a team of air bag builders and ensure productivity and efficiency?

Sample Answer: I manage a team of air bag builders by:

- Setting clear goals and expectations.

- Providing training and support.

- Monitoring progress and providing feedback.

- Empowering team members to make decisions.

10. What are your strengths and weaknesses as an air bag builder?

Sample Answer: My strengths as an air bag builder include:

- Technical expertise: I have a strong understanding of air bag technology and manufacturing processes.

- Quality-oriented: I am committed to producing high-quality air bags that meet safety standards.

- Team player: I work well in a team environment and am able to collaborate effectively with others.

My weaknesses include:

- Lack of experience in a leadership role: I have not yet had the opportunity to lead a team of air bag builders.

- Limited experience with certain types of air bags: I have more experience with frontal and side air bags than with curtain and knee air bags.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Bag Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Bag Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Bag Builders play a crucial role in manufacturing, assembling, and testing airbags, ensuring the safety of vehicles and their occupants. Their responsibilities encompass a range of tasks, including:

1. Manufacturing and Assembly

Assembling airbag modules and inflators following defined specifications and procedures

- Inspecting and testing airbag components for defects and proper functioning

- Ensuring compliance with safety regulations and quality standards

2. Testing and Evaluation

Conducting performance tests on airbags to verify their deployment and inflation characteristics

- Analyzing test data and identifying areas for improvement

- Providing feedback to engineers and designers to optimize airbag design

3. Maintenance and Troubleshooting

Performing regular maintenance on airbag assembly equipment

- Diagnosing and resolving any issues or malfunctions

- Calibrating and servicing equipment to ensure accurate performance

4. Quality Control

Monitoring and maintaining quality standards throughout the airbag manufacturing process

- Inspecting incoming materials and components for compliance

- Conducting audits and ensuring adherence to safety protocols

Interview Tips

To ace your interview for an Air Bag Builder position, it’s essential to prepare thoroughly and present yourself confidently. Here are some tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, products, and recent developments

- Read industry news and stay up-to-date with the latest trends in airbag technology

- This shows the interviewer that you’re genuinely interested in the role and have taken the initiative to learn about the company

2. Highlight Your Technical Skills

Emphasize your knowledge of airbag manufacturing, testing, and quality control processes

- Provide specific examples of your experience using relevant equipment or software

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact

3. Show Your Attention to Detail

Airbag Builders must have a keen eye for detail

- Highlight your ability to work meticulously and follow instructions precisely

- Describe a situation where your attention to detail led to a positive outcome

4. Demonstrate Your Problem-Solving Abilities

Describe a situation where you successfully resolved an airbag-related issue

- Explain your thought process and the steps you took to troubleshoot and fix the problem

- This demonstrates your analytical and problem-solving skills

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Air Bag Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!