Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Air Compressor Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Air Compressor Engineer so you can tailor your answers to impress potential employers.

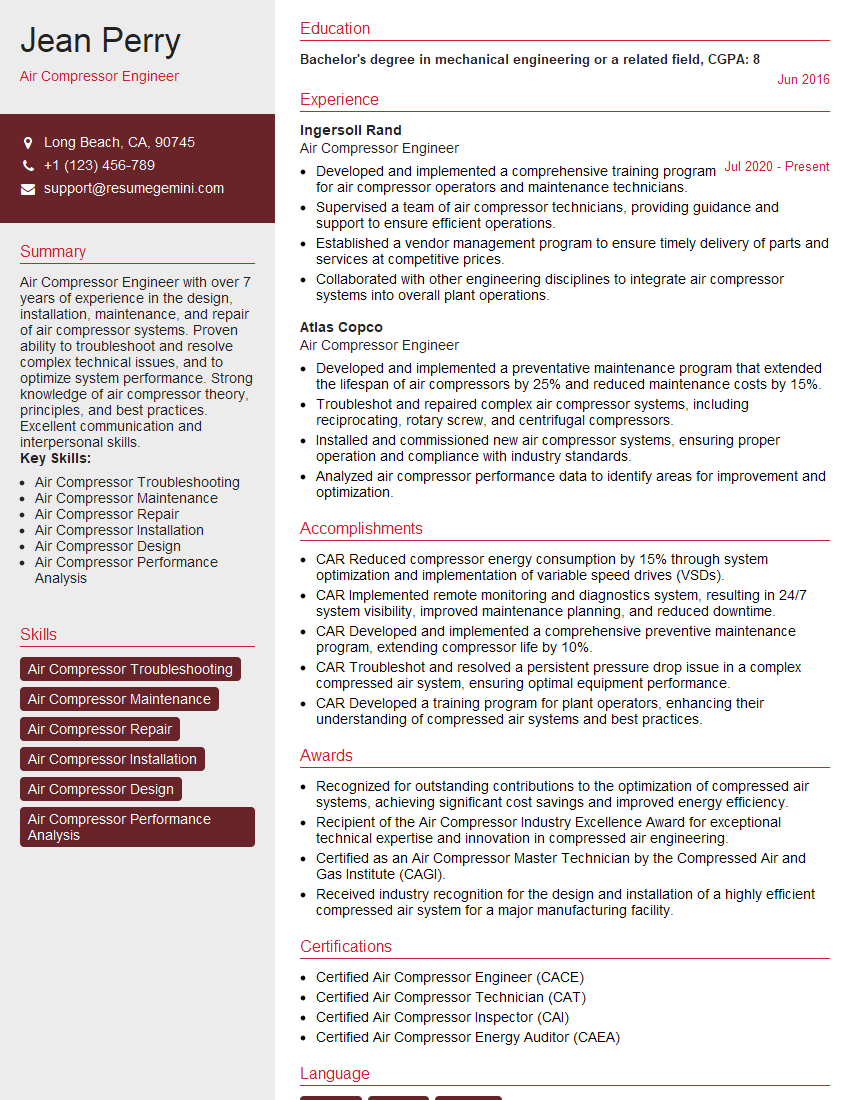

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Compressor Engineer

1. Explain the working principle of a reciprocating air compressor?

In a reciprocating air compressor, a piston moves within a cylinder, compressing air as it moves.

- The piston is connected to a crankshaft, which converts the reciprocating motion of the piston into rotary motion.

- As the piston moves up, it compresses the air in the cylinder, increasing its pressure.

- The compressed air is then discharged through a check valve.

2. What are the different types of air compressors?

There are various types of air compressors, including:

- Reciprocating air compressors: These use a piston to compress air in a cylinder.

- Rotary air compressors: These use rotating components to compress air.

- Screw air compressors: These use a pair of meshing screws to compress air.

- Centrifugal air compressors: These use a spinning impeller to compress air.

3. What are the factors that affect the efficiency of an air compressor?

The efficiency of an air compressor is affected by several factors, including:

- The type of compressor: Different types of compressors have different efficiencies.

- The size of the compressor: Larger compressors are typically more efficient than smaller ones.

- The operating conditions: The efficiency of a compressor can be affected by factors such as the intake air temperature, the discharge pressure, and the altitude.

4. What are the common problems that can occur with air compressors?

Common problems with air compressors include:

- Overheating: This can be caused by a variety of factors, such as inadequate cooling, excessive load, or dirty air filters.

- Leaking: This can occur from various points in the compressor, such as the seals, gaskets, or valves.

- Vibration: This can be caused by an unbalanced compressor, loose bolts, or worn bearings.

5. How do you troubleshoot an air compressor that is not working properly?

To troubleshoot an air compressor, follow these steps:

- Check the power supply: Make sure that the compressor is plugged in and that the power switch is turned on.

- Check the air filter: A dirty air filter can restrict airflow and cause the compressor to overheat.

- Check the oil level: Low oil levels can cause the compressor to overheat and seize up.

- Check the belts: Loose or worn belts can cause the compressor to lose power.

6. How do you maintain an air compressor?

To maintain an air compressor, follow these steps:

- Regularly change the air filter: A dirty air filter can restrict airflow and cause the compressor to overheat.

- Check the oil level: Low oil levels can cause the compressor to overheat and seize up.

- Check the belts: Loose or worn belts can cause the compressor to lose power.

- Clean the compressor regularly: Dirt and dust can build up on the compressor and cause it to overheat.

7. What are the safety precautions that should be taken when working with air compressors?

When working with air compressors, always take the following safety precautions:

- Wear ear protection: Air compressors can be noisy, so it is important to wear ear protection to prevent hearing damage.

- Wear eye protection: Air compressors can discharge debris, so it is important to wear eye protection to prevent eye injuries.

- Never point the air nozzle at yourself or others: Air compressors can discharge air at high pressure, which can cause serious injuries.

8. What are the different applications of air compressors?

Air compressors are used in a wide variety of applications, including:

- Construction: Air compressors are used to power pneumatic tools, such as drills, sanders, and impact wrenches.

- Manufacturing: Air compressors are used to power pneumatic actuators, such as cylinders and valves.

- Automotive: Air compressors are used to fill tires and power pneumatic tools.

9. What are the advantages of using an air compressor?

Air compressors offer several advantages, including:

- Versatility: Air compressors can be used to power a wide variety of tools and equipment.

- Portability: Air compressors are relatively portable, so they can be easily moved around to different locations.

- Reliability: Air compressors are reliable and can operate for long periods of time without requiring maintenance.

10. What are the disadvantages of using an air compressor?

Air compressors also have some disadvantages, including:

- Noise: Air compressors can be noisy, especially when they are running at high pressure.

- Energy consumption: Air compressors can consume a lot of energy, especially when they are used for extended periods of time.

- Maintenance: Air compressors require regular maintenance, such as changing the air filter and oil.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Compressor Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Compressor Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Compressor Engineers play a vital role in the maintenance and operation of industrial equipment. Their primary responsibilities include:

1. Compressor Maintenance and Troubleshooting

Diagnose and repair compressor malfunctions, vibrations, leaks, and other issues.

- Inspect compressors for wear and tear, and replace or repair damaged parts.

- Lubricate and adjust compressors to ensure optimal performance.

2. Compressor Installation and Modifications

Install, relocate, and modify air compressors and related equipment.

- Follow engineering specifications and safety regulations during installation.

- Test and document system performance after modifications.

3. Air Quality Management

Monitor and control air quality to ensure it meets industry standards.

- Perform air quality tests and recommend corrective actions as needed.

- Collaborate with other departments to optimize air quality and energy efficiency.

4. Energy Efficiency

Evaluate and optimize energy consumption of air compressors.

- Identify and implement energy-saving measures.

- Monitor compressor performance and make recommendations for improvement.

Interview Tips

To ace the interview for an Air Compressor Engineer position, it’s essential to prepare thoroughly and highlight your relevant skills and experience. Here are some tips:

1. Research the Company and Industry

Learn about the company’s business, products, and market position. Understanding the industry’s challenges and trends will demonstrate your interest and knowledge.

- Visit the company’s website and read industry publications.

- Attend industry events and conferences to network and expand your knowledge.

2. Practice Your Technical Skills

Review the key job responsibilities and identify the technical skills required. Brush up on your knowledge of air compressor systems, maintenance procedures, and troubleshooting techniques.

- Solve practice problems and review case studies to demonstrate your analytical abilities.

- Prepare examples of successful projects where you applied your technical expertise.

3. Highlight Your Communication and Problem-Solving Skills

Air Compressor Engineers often work with a variety of teams, including maintenance technicians, operators, and managers. Strong communication and problem-solving skills are essential.

- Provide examples of how you effectively communicated technical information to non-experts.

- Describe your approach to problem-solving and decision-making, emphasizing your analytical and logical thinking abilities.

4. Quantify Your Experience and Accomplishments

Use specific numbers and metrics to demonstrate the impact of your work. When describing your experience and accomplishments, quantify your results whenever possible.

- For example, instead of saying “Improved compressor efficiency,” you could say “Implemented energy-saving measures that reduced energy consumption by 15%.”.

- Provide concrete examples of how you contributed to the success of previous projects.

Next Step:

Now that you’re armed with the knowledge of Air Compressor Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Air Compressor Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini