Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Compressor Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

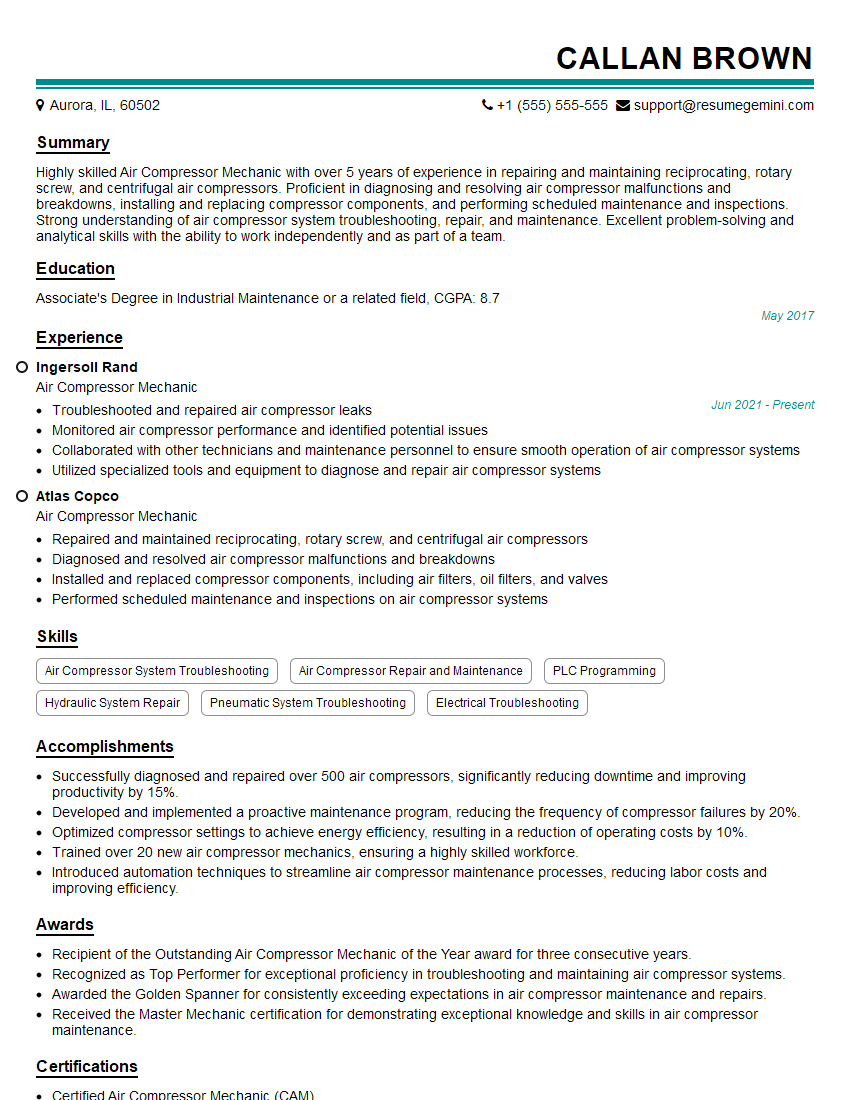

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Compressor Mechanic

1. Explain the working principle of a reciprocating air compressor?

A reciprocating air compressor works by converting the reciprocating motion of a piston into the compression of air. The piston is driven by a crankshaft, and as it moves back and forth in the cylinder, it compresses the air inside. The compressed air is then discharged from the cylinder through a check valve.

- The piston moves back and forth in the cylinder, compressing the air inside.

- The compressed air is then discharged from the cylinder through a check valve.

2. What are the different types of air compressors?

- Reciprocating air compressors

- Rotary screw air compressors

- Centrifugal air compressors

- Axial air compressors

3. What are the factors to consider when selecting an air compressor?

- The required air flow rate

- The required air pressure

- The type of application

- The available space

- The budget

4. How do you maintain an air compressor?

- Check the oil level and change the oil regularly.

- Inspect the air filter and replace it if necessary.

- Check the belts and hoses for wear and tear.

- Drain the water from the air tank.

- Have the air compressor serviced by a qualified technician on a regular basis.

5. What are the common problems that can occur with air compressors?

- Low air pressure

- Leaking air

- Overheating

- Electrical problems

- Mechanical problems

6. How do you troubleshoot an air compressor?

- Check the air filter.

- Check the oil level.

- Check the belts and hoses.

- Check the electrical connections.

- Listen for unusual noises.

7. What are the safety precautions that should be taken when working with air compressors?

- Wear eye protection.

- Wear hearing protection.

- Do not operate an air compressor in a confined space.

- Do not use an air compressor to blow dust or debris off of yourself or others.

- Do not point an air compressor at anyone.

8. What are the different types of air compressor oils?

- Mineral oil

- Synthetic oil

- Semi-synthetic oil

9. How often should the oil in an air compressor be changed?

- Every 500 hours of operation

- Every 6 months

- Every year

10. What are the benefits of using a rotary screw air compressor?

- They are more efficient than reciprocating air compressors.

- They produce a more consistent air flow.

- They are quieter than reciprocating air compressors.

- They have a longer lifespan than reciprocating air compressors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Compressor Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Compressor Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Air Compressor Mechanic plays a vital role in ensuring the smooth operation and maintenance of air compressor systems in various industries. Key job responsibilities include:

1. Installation and Maintenance

Installing, maintaining, and repairing air compressors, dryers, and related components.

- Conducting periodic inspections, testing, and troubleshooting to prevent breakdowns and ensure optimal performance.

- Replacing worn or damaged parts, such as filters, belts, valves, and bearings.

2. Troubleshooting and Repairs

Diagnosing and resolving mechanical problems with air compressors and their components.

- Analyzing system performance, identifying potential issues, and implementing effective solutions.

- Using diagnostic tools and techniques to pinpoint root causes of malfunctions.

3. Overhauling and Rebuilding

Performing major repairs and overhauls on air compressors and their components.

- Disassembling, cleaning, and inspecting internal parts, such as pistons, valves, and bearings.

- Replacing or repairing damaged components, including seals, gaskets, and O-rings.

4. Preventive Maintenance

Developing and implementing preventive maintenance plans to extend the lifespan and efficiency of air compressor systems.

- Monitoring system performance, such as pressure, temperature, and flow rates.

- Scheduling regular maintenance tasks, such as lubrication, filter changes, and performance testing.

5. Safety and Compliance

Maintaining a safe work environment and complying with all applicable safety regulations.

- Ensuring proper ventilation and handling of hazardous materials.

- Using personal protective equipment (PPE) and following established safety protocols.

- Staying up-to-date on industry best practices and technological advancements.

6. Communication and Documentation

Communicating effectively with colleagues, supervisors, and customers.

- Documenting maintenance procedures, repairs, and system performance.

- Providing technical guidance and support to other team members.

Interview Tips

To ace an interview for an Air Compressor Mechanic position, here are some tips and preparation hacks:

1. Research the Company and Position

Familiarize yourself with the company’s operations, industry standing, and specific requirements for the Air Compressor Mechanic role. This demonstrates your interest and enthusiasm for the position.

- Visit the company’s website, read industry articles, and connect with employees on LinkedIn to gain insights.

- Review the job description thoroughly to identify key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as air compressor maintenance, troubleshooting, and repair. Quantify your accomplishments whenever possible to showcase your impact.

- Provide specific examples of projects where you successfully diagnosed and resolved air compressor issues.

- Mention any certifications, training, or specialized knowledge you have in air compressor systems.

3. Demonstrate Problem-Solving Abilities

Air Compressor Mechanics must be skilled at problem-solving. Share examples of how you approached and resolved complex technical challenges.

- Describe a situation where you identified a recurring issue and implemented a solution that prevented future breakdowns.

- Explain how you used diagnostic tools and techniques to pinpoint root causes of system malfunctions.

4. Emphasize Safety and Compliance

Safety is paramount in this role. Highlight your commitment to maintaining a safe work environment and complying with all applicable regulations.

- Explain how you ensure proper ventilation and handle hazardous materials safely.

- Mention any safety training or certifications you have obtained.

5. Prepare Technical Questions

Anticipate technical questions during the interview. Prepare answers that showcase your understanding of air compressor systems and industry best practices.

- Review common air compressor components, such as compressors, dryers, and filters.

- Familiarize yourself with troubleshooting techniques and diagnostic tools used in air compressor maintenance.

6. Practice and Seek Feedback

Practice your answers to common interview questions out loud. Ask a friend or family member to provide feedback on your responses and areas for improvement.

- Conduct mock interviews to simulate the real interview experience.

- Record yourself answering questions and review your performance.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive punctually to demonstrate respect and punctuality.

- Choose attire that is appropriate for the work environment and industry.

- Plan your route in advance to avoid delays and arrive at the interview location on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Air Compressor Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.