Feeling lost in a sea of interview questions? Landed that dream interview for Air Compressor Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Air Compressor Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

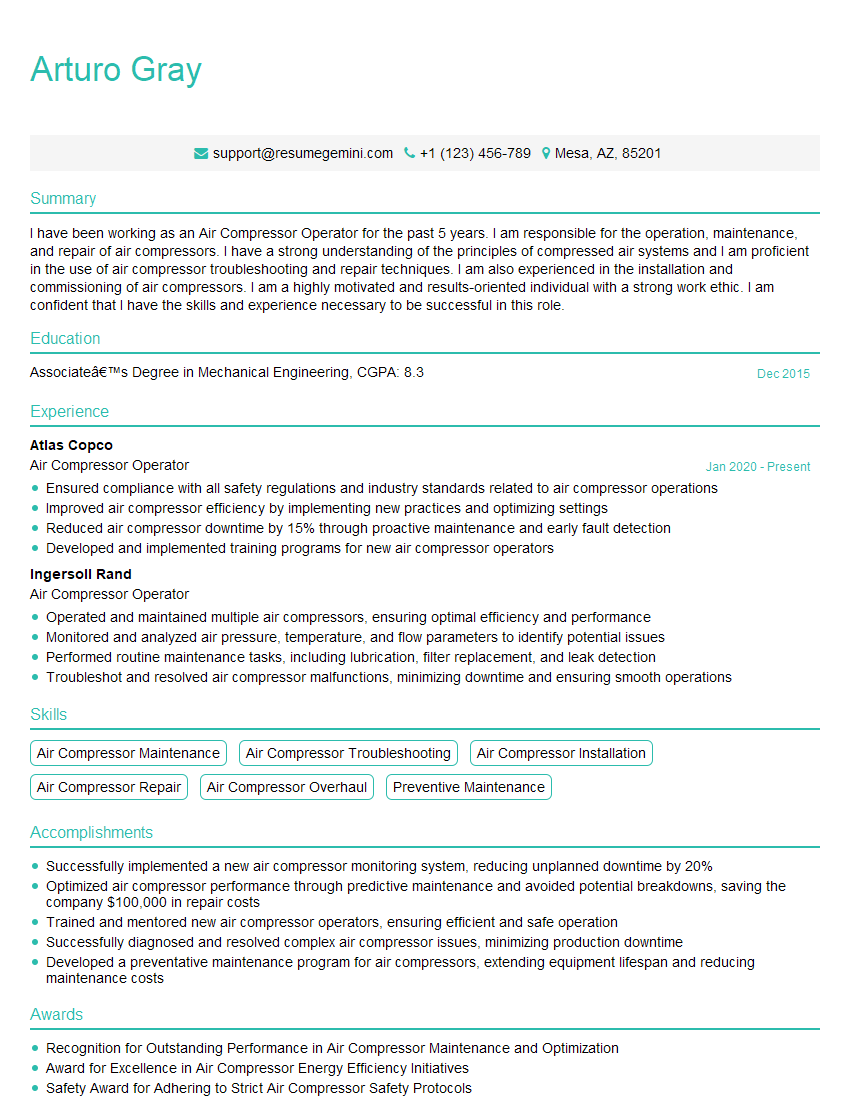

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Compressor Operator

1. Describe the basic components of an air compressor system?

An air compressor system typically consists of the following components:

- Air compressor: The main component of the system, which compresses air to the desired pressure.

- Air receiver: A tank that stores the compressed air and maintains a constant pressure.

- Air filter: Removes impurities and moisture from the compressed air.

- Pressure regulator: Controls the pressure of the compressed air delivered to the system.

- Piping and fittings: Connects the components of the system and directs the flow of compressed air.

2. Explain the different types of air compressors and their applications?

Reciprocating compressors

- Positive displacement compressors that use pistons to compress air.

- Suitable for small to medium applications, such as powering pneumatic tools and inflating tires.

Rotary screw compressors

- Positive displacement compressors that use rotating screws to compress air.

- More efficient and quieter than reciprocating compressors.

- Used in industrial applications, such as powering large machinery and air conditioning systems.

Centrifugal compressors

- Dynamic compressors that use high-speed rotating impellers to compress air.

- Used for high-volume, low-pressure applications, such as air conditioning and refrigeration.

3. How do you ensure the safety of an air compressor system?

Ensuring the safety of an air compressor system involves adhering to the following measures:

- Regular maintenance and inspections to identify and address potential hazards.

- Proper installation and ventilation to prevent overheating and explosions.

- Use of safety guards and protective devices to prevent contact with moving parts.

- Training and instruction for operators on safe operation and emergency procedures.

- Compliance with relevant safety regulations and standards.

4. What are the common troubleshooting techniques for air compressor systems?

Common troubleshooting techniques include:

- Checking the air filter for clogs and replacing if necessary.

- Inspecting the pressure regulator and adjusting it to the desired pressure.

- Examining the air receiver for leaks and repairing or replacing any damaged seals.

- Listening for unusual noises or vibrations and identifying the source of the issue.

- Consulting with a qualified technician for more complex problems.

5. Explain the importance of regular maintenance for air compressor systems?

Regular maintenance is crucial for air compressor systems because it ensures:

- Optimal performance and efficiency.

- Reduced downtime and increased lifespan.

- Enhanced safety by preventing breakdowns and accidents.

- Compliance with manufacturer’s recommendations and industry standards.

- Lower operating costs through timely detection and correction of issues.

6. Describe the role of an air compressor operator in maintaining the system?

An air compressor operator is responsible for:

- Monitoring the system’s performance and identifying any potential issues.

- Performing routine maintenance tasks, such as changing air filters and checking oil levels.

- Troubleshooting and resolving minor problems.

- Coordinating with maintenance personnel for more complex repairs.

- Ensuring that the system is operated safely and efficiently.

7. How do you handle emergencies involving air compressor systems?

In case of emergencies involving air compressor systems, I would:

- Immediately shut down the system and secure the power source.

- Identify the cause of the emergency and take appropriate action.

- Contact a qualified technician if the problem cannot be resolved on-site.

- Alert other personnel in the area and ensure their safety.

- Document the incident and report it to the supervisor.

8. Can you explain the concept of air compressor capacity and how it is calculated?

Air compressor capacity refers to the volume of air it can deliver at a specified pressure. It is typically measured in cubic feet per minute (CFM) or liters per minute (LPM). The capacity of an air compressor is calculated based on the following formula:

- Capacity (CFM) = Piston Displacement (CFM) x Compressor Speed (RPM) / 1,728

9. What factors should be considered when selecting an air compressor for a specific application?

When selecting an air compressor for a specific application, the following factors should be taken into account:

- Required air flow rate (CFM or LPM)

- Operating pressure (PSI or BAR)

- Type of application (e.g., industrial, commercial, residential)

- Duty cycle (continuous or intermittent)

- Available power source (electricity, gasoline, diesel)

- Noise level considerations

- Maintenance requirements

- Cost and budget

10. Can you describe the different types of air compressor controls and their functions?

Air compressor controls are used to regulate the operation of the compressor and maintain the desired air pressure. Common types of air compressor controls include:

- Pressure switch: Turns the compressor on and off based on the air pressure in the receiver tank.

- Unloader valve: Bypasses air from the compressor’s output when the desired pressure is reached.

- Capacity control: Adjusts the compressor’s output to match the demand for air.

- Sequencing controls: Used in multiple-compressor systems to ensure that compressors operate efficiently and reduce wear.

- PLC (Programmable Logic Controller): Advanced controls that provide sophisticated monitoring, control, and protection functions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Compressor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Compressor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Compressor Operators play a crucial role in maintaining optimal air pressure levels for industrial processes and equipment. Their key responsibilities include:

1. Operating and Maintaining Air Compressors

Starting, stopping, and adjusting air compressors to ensure efficient operation and adherence to manufacturer specifications.

- Monitoring compressor performance parameters (pressure, temperature, oil level, etc.)

- Performing routine maintenance tasks (greasing, changing filters, inspecting belts)

2. Diagnosing and Troubleshooting Compressor Faults

Identifying and resolving compressor malfunctions, minimizing downtime and ensuring uninterrupted air supply.

- Analyzing error codes and identifying root causes

- Performing necessary repairs and adjustments

3. Ensuring Air Pressure and Quality

Adjusting compressor settings to maintain optimal air pressure levels for various applications.

- Monitoring air quality, including dew point and contamination

- Taking corrective actions to ensure clean and dry air supply

4. Following Safety Procedures and Regulations

Adhering to established safety protocols for compressor operation and maintenance.

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Reporting any safety hazards or incidents promptly

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace the interview for an Air Compressor Operator position:

1. Research the Industry and Company

Demonstrate your knowledge of the industry and the specific company you’re applying to. This shows that you’re genuinely interested in the role and have taken the time to understand their needs.

- Read through the company website and industry publications

- Check out their social media profiles and follow industry news

2. Highlight Your Experience and Skills

Emphasize your relevant experience operating and maintaining air compressors. Quantify your accomplishments whenever possible.

- Describe specific instances where you diagnosed and resolved compressor issues

- Mention your experience with different types of air compressors

3. Demonstrate Your Safety Mindset

Safety is paramount in this role. Highlight your understanding of safety protocols and your adherence to them.

- Explain your knowledge of lockout/tagout procedures

- Describe how you ensure proper PPE usage and maintain a safe work environment

4. Be Prepared for Technical Questions

Expect questions related to air compressor operation, troubleshooting, and maintenance.

- Review the basics of air compressor systems (e.g., types, components, principles of operation)

- Practice troubleshooting scenarios and explain your approach to resolving them

5. Show Enthusiasm and Ask Questions

Express your passion for the role and show that you’re eager to learn and contribute. Asking thoughtful questions demonstrates your engagement and interest in the position.

- Inquire about the company’s specific equipment, maintenance practices, or industry challenges

- Ask about opportunities for professional development and growth within the organization

Next Step:

Now that you’re armed with the knowledge of Air Compressor Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Air Compressor Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini