Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Conditioning Coil Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

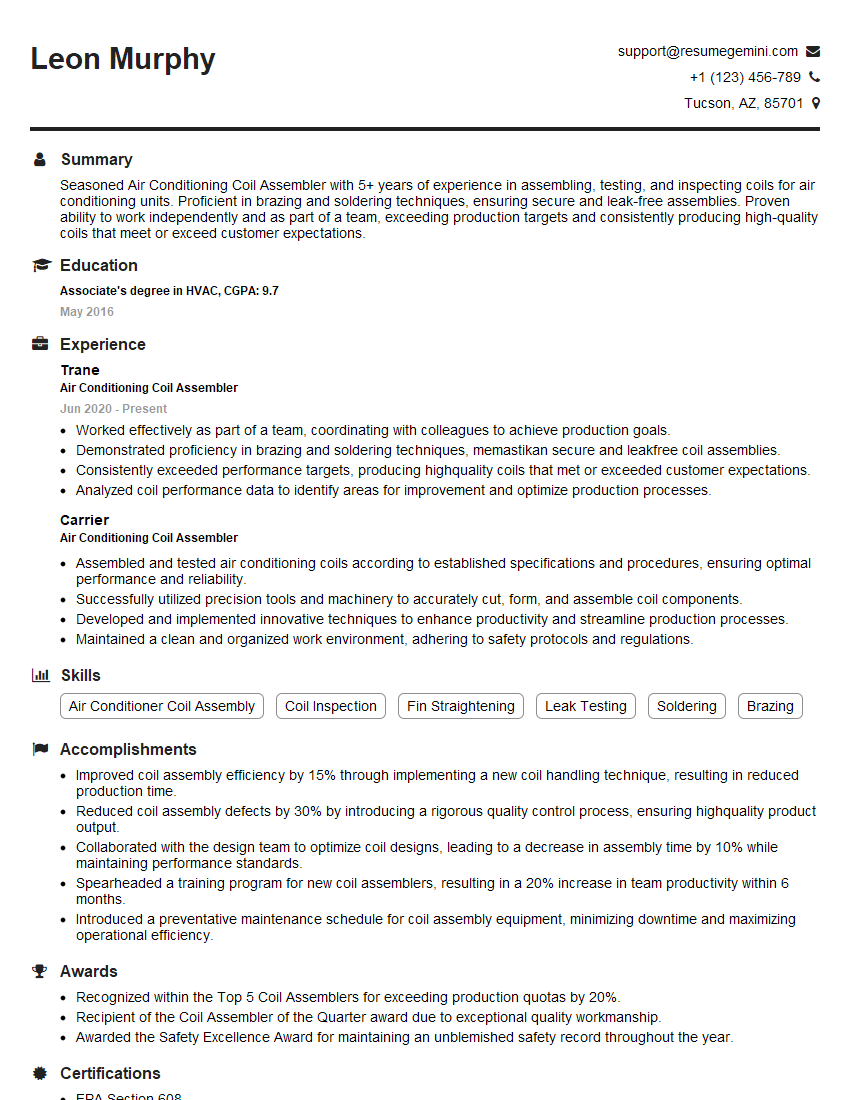

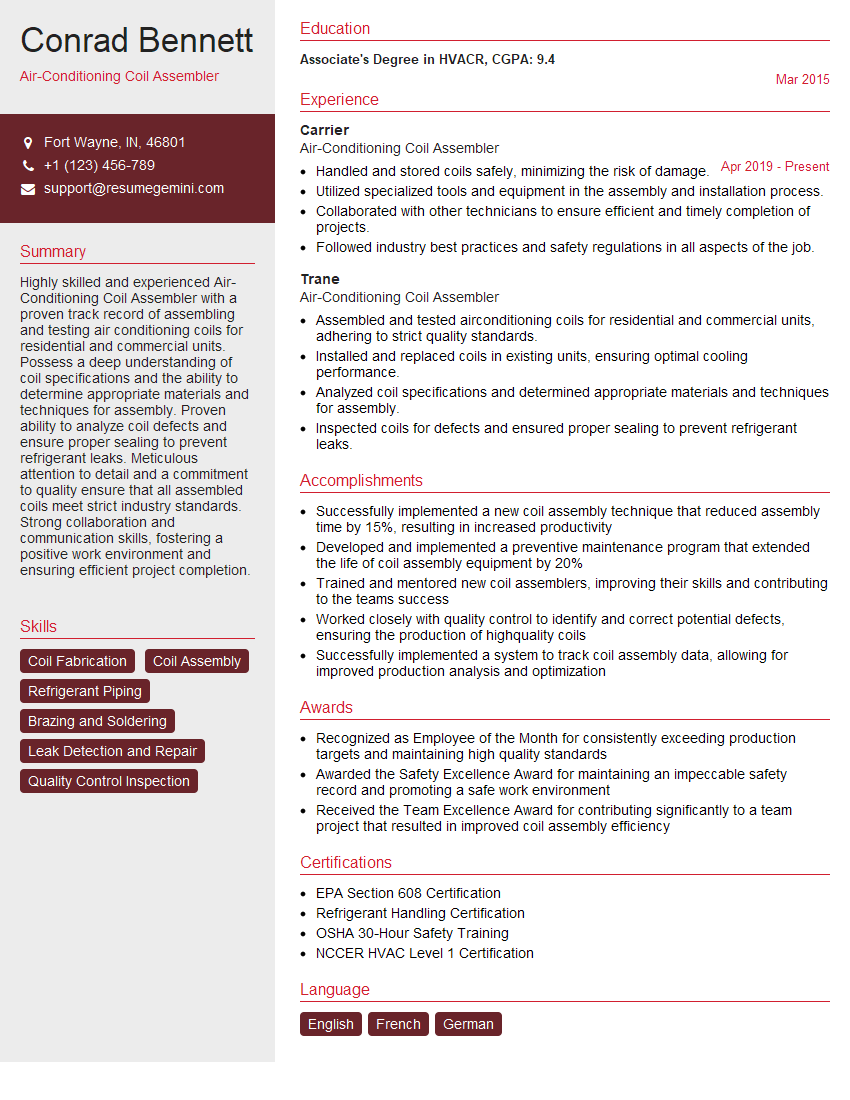

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Conditioning Coil Assembler

1. Describe the process of assembling an air conditioning coil.

Sample Answer: The process of assembling an air conditioning coil involves the following steps:

- Unpacking and inspecting the coil components

- Assembling the coil headers

- Installing the tubes into the headers

- Expanding the tubes into the headers

- Cleaning and testing the coil

2. What are the different types of air conditioning coils?

Types of Condenser Coils

- Plate-fin Coil

- MicroChannel Coil

- Serpentine Coil

Types of Evaporator Coils

- A-Coil

- W-Coil

- Straight Coil

3. What are the most common problems associated with air conditioning coils?

Sample Answer: The most common problems associated with air conditioning coils include:

- Dirt and debris accumulation

- Corrosion

- Leaks

- Freezing

4. How can you prevent problems with air conditioning coils?

Sample Answer: Problems with air conditioning coils can be prevented by:

- Regularly cleaning the coils

- Inspecting the coils for corrosion and leaks

- Ensuring that the coils are properly sized for the unit

- Using a coil cleaner to remove dirt and debris

5. What are the safety precautions that must be taken when working with air conditioning coils?

Sample Answer: When working with air conditioning coils, it is important to take the following safety precautions:

- Wear gloves and eye protection

- Do not touch the coils with bare hands

- Be aware of the potential for electrical shock

- Use proper tools and equipment

6. What are the different types of materials used in the construction of air conditioning coils?

- Copper

- Aluminum

- Steel

- Stainless steel

7. What are the different sizes of air conditioning coils?

Sample Answer: Air conditioning coils come in a variety of sizes, depending on the capacity of the unit. The most common sizes are 12 inches, 18 inches, and 24 inches.

8. What are the different shapes of air conditioning coils?

- Round

- Square

- Rectangular

- Oval

9. What are the benefits of using air conditioning coils?

- Improved cooling efficiency

- Reduced energy consumption

- Lower operating costs

- Increased reliability

10. What are the challenges of working with air conditioning coils?

- The coils can be delicate and easily damaged

- The coils can be difficult to clean

- The coils can be dangerous to work with if they are not properly insulated

- The coils can be expensive to replace

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Conditioning Coil Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Conditioning Coil Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Conditioning Coil Assemblers play a crucial role in the assembly and installation of cooling systems, ensuring optimal performance and efficiency. Their responsibilities include:

1. Assembling and Installing Air Conditioning Coils

Assembling and installing air conditioning coils, including evaporating and condensing coils, according to blueprints and specifications.

- Verifying dimensions and specifications of coils and components.

- Using specialized tools and equipment to assemble and connect coils.

2. Brazing and Soldering Copper Tubing

Brazing and soldering copper tubing to connect coils and create refrigerant flow paths.

- Preparing and cleaning copper tubing surfaces for brazing.

- Applying flux and solder to create leak-proof joints.

3. Testing and Inspecting Coils

Conducting pressure tests and visual inspections to ensure coils are leak-proof and meet quality standards.

- Pressurizing coils with nitrogen or other inert gases.

- Checking for leaks using soap solutions and electronic leak detectors.

4. Troubleshooting and Repairing Coils

Troubleshooting and repairing faulty coils to maintain optimal performance.

- Diagnosing issues based on symptoms and error codes.

- Replacing or repairing damaged coils and components.

Interview Tips

Preparing for an Air Conditioning Coil Assembler interview requires thorough research, practice, and a confident demeanor. Here are some tips to help you ace the interview:

1. Know the Job and Industry

Familiarize yourself with the job responsibilities, industry trends, and best practices. Research different types of air conditioning coils, assembly techniques, and troubleshooting methods. This knowledge will demonstrate your interest and understanding of the role.

2. Practice Your Skills

Practice assembling and soldering copper tubing. If possible, set up a mock workstation to simulate real-world conditions. This will build your confidence and demonstrate your proficiency during the interview.

3. Highlight Your Experience

Quantify your experience and accomplishments whenever possible. Use specific examples to showcase your skills in assembling, inspecting, and repairing air conditioning coils. Emphasize your ability to work independently and as part of a team.

4. Be Prepared for Technical Questions

Be prepared to answer technical questions related to the job. This may include questions on coil design, refrigeration principles, and troubleshooting techniques. Your knowledge and ability to articulate complex concepts will impress the interviewer.

5. Show Your Passion

Express your enthusiasm for the HVAC industry and your desire to excel in the role. Demonstrate your eagerness to learn and grow within the organization. A positive attitude and a willingness to take on challenges will make you stand out.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Air Conditioning Coil Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.