Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Tool Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

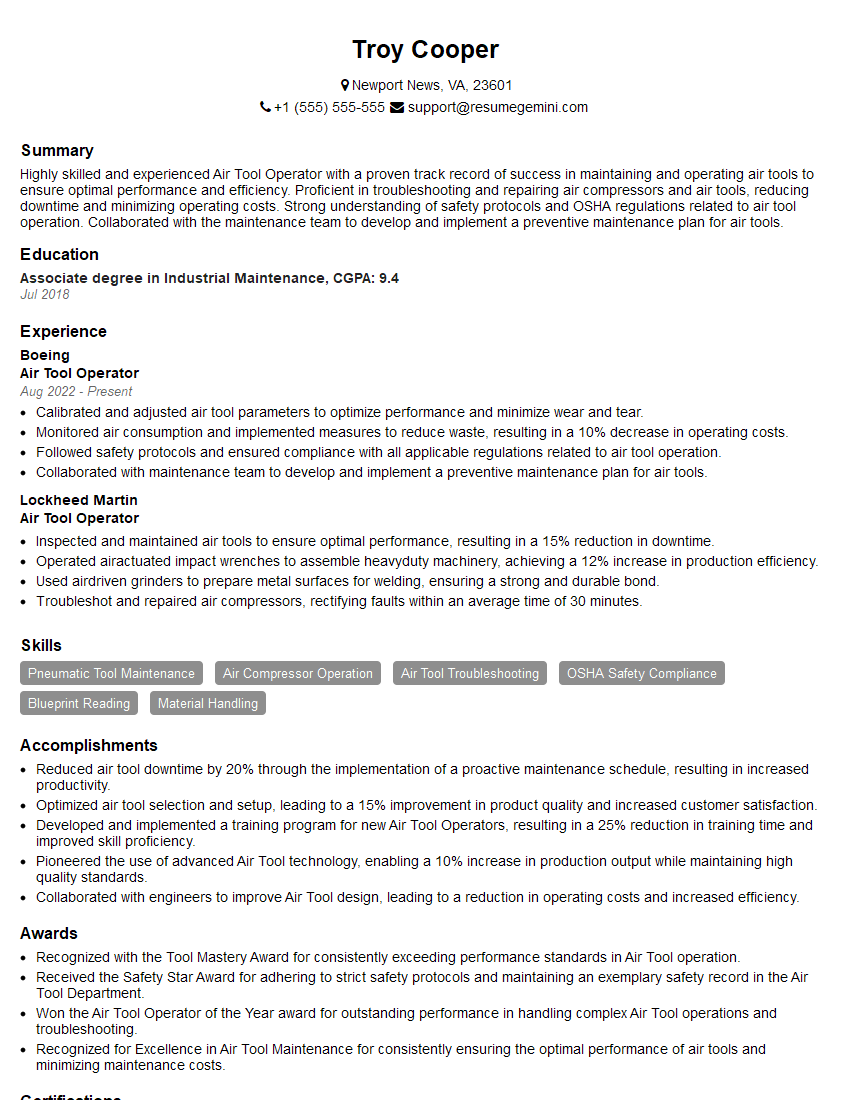

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Tool Operator

1. Explain the different types of air tools and their applications?

• Pistol-grip air drills for drilling holes in various materials.

• Rotary air motors for powering industrial machinery.

• Air hammers for breaking concrete or driving nails.

• Air sanders for sanding wood or metal.

• Air nailers for framing and finishing applications.

2. How do you maintain air tools to ensure their optimal performance?

Periodic Maintenance

- Lubricating moving parts with air tool oil.

- Inspecting hoses and fittings for leaks and damage.

Troubleshooting

- Inspecting air filters for clogging.

- Adjusting air pressure to the correct level.

- Replacing worn or damaged parts.

3. What are the safety precautions you observe when operating air tools?

• Wearing safety glasses, earplugs, and gloves.

• Inspecting tools before each use and ensuring they are in good condition.

• Using tools only for their intended purposes.

• Never pointing tools at anyone or yourself.

• Releasing air pressure from tools before disconnecting or changing accessories.

4. How do you calculate the air consumption of an air tool?

Air consumption (CFM) = (CFM rating of tool) x (Duty cycle as a percentage) x (Number of tools)

5. What are the common problems encountered with air tools and how do you troubleshoot them?

• Air leaks: Inspect hoses, fittings, and the tool itself for leaks and repair or replace as needed.

• Low power: Check air pressure, clean or replace air filters, and inspect the tool for blockages.

• Erratic operation: Inspect valves, diaphragms, and other moving parts for wear or damage and replace as necessary.

6. How do you ensure that air tools are used efficiently in a production setting?

• Proper tool selection for the job.

• Regular maintenance and troubleshooting to prevent downtime.

• Training operators on proper tool usage and safety.

• Establishing a system for tool storage and inventory management.

7. What are the different types of air compressors used to power air tools?

• Reciprocating air compressors: Use a piston to compress air.

• Rotary screw air compressors: Use rotating screws to compress air.

• Centrifugal air compressors: Use centrifugal force to compress air.

8. How do you determine the appropriate air pressure for an air tool?

Refer to the manufacturer’s specifications for the tool.

• Higher pressure provides more power but can also increase wear and tear.

• Lower pressure reduces power but extends tool life.

9. What are the environmental considerations related to air tool operation?

• Noise pollution: Air tools can generate significant noise, requiring the use of hearing protection.

• Air pollution: Exhaust from air compressors contains oil and moisture, which can contribute to air quality issues.

10. How do you stay updated on the latest advancements in air tool technology?

• Attending industry trade shows and conferences.

• Reading technical publications and online resources.

• Consulting with manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Tool Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Tool Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Tool Operators are responsible for the safe and efficient operation of air-powered tools in industrial or construction settings. Their primary tasks include:

1. Tool Operation and Maintenance

Operate various air-powered tools, such as drills, grinders, sanders, and impact wrenches.

- Inspect tools before use to ensure they are in good working condition.

- Set up and calibrate tools according to job specifications.

2. Material Fabrication and Assembly

Use air tools to fabricate or assemble components or products.

- Drill holes, tighten bolts, or sand surfaces.

- Maintain a clean and organized work area.

3. Quality Assurance

Inspect finished products or components for defects or errors.

- Use air tools to verify dimensions or tolerances.

- Report any discrepancies to supervisors.

4. Safety and Compliance

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE).

- Handle air tools responsibly and avoid accidents.

Interview Tips

Preparing for an Air Tool Operator interview requires a combination of technical knowledge, soft skills, and understanding the company’s culture. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Understand the specific job duties and responsibilities of the Air Tool Operator role. Visit the company’s website, LinkedIn page, and read industry news to gather information.

- Practice answering common interview questions related to your experience with air tools and safety procedures.

- Prepare questions to ask the interviewer about the company, the role, and the team you would be working with.

2. Highlight Your Technical Skills

Demonstrate your proficiency in operating various air-powered tools, including their capabilities, limitations, and safety precautions. Describe your experience in material fabrication, assembly, and quality assurance.

- Provide specific examples of how you have used air tools to solve problems or improve efficiency in previous roles.

- Quantify your accomplishments whenever possible, using metrics such as increased productivity or reduced downtime.

3. Emphasize Safety and Compliance

Stress your commitment to safety and compliance. Explain your understanding of relevant industry regulations and best practices. Describe your experience in handling air tools responsibly and preventing accidents.

- Explain how you stay up-to-date on safety regulations and ensure that your work meets or exceeds industry standards.

- Provide examples of situations where you identified and mitigated safety hazards in previous roles.

4. Showcase Your Soft Skills

Beyond technical skills, Air Tool Operators also require good communication, teamwork, and problem-solving abilities. Highlight your experience working with diverse teams, resolving conflicts, and adapting to changing priorities.

- Use the STAR method (Situation, Task, Action, Result) to describe how you handled challenging situations in the past.

- Emphasize your willingness to learn, ask questions, and contribute to the team’s success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Air Tool Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Air Tool Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.