Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Twist Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

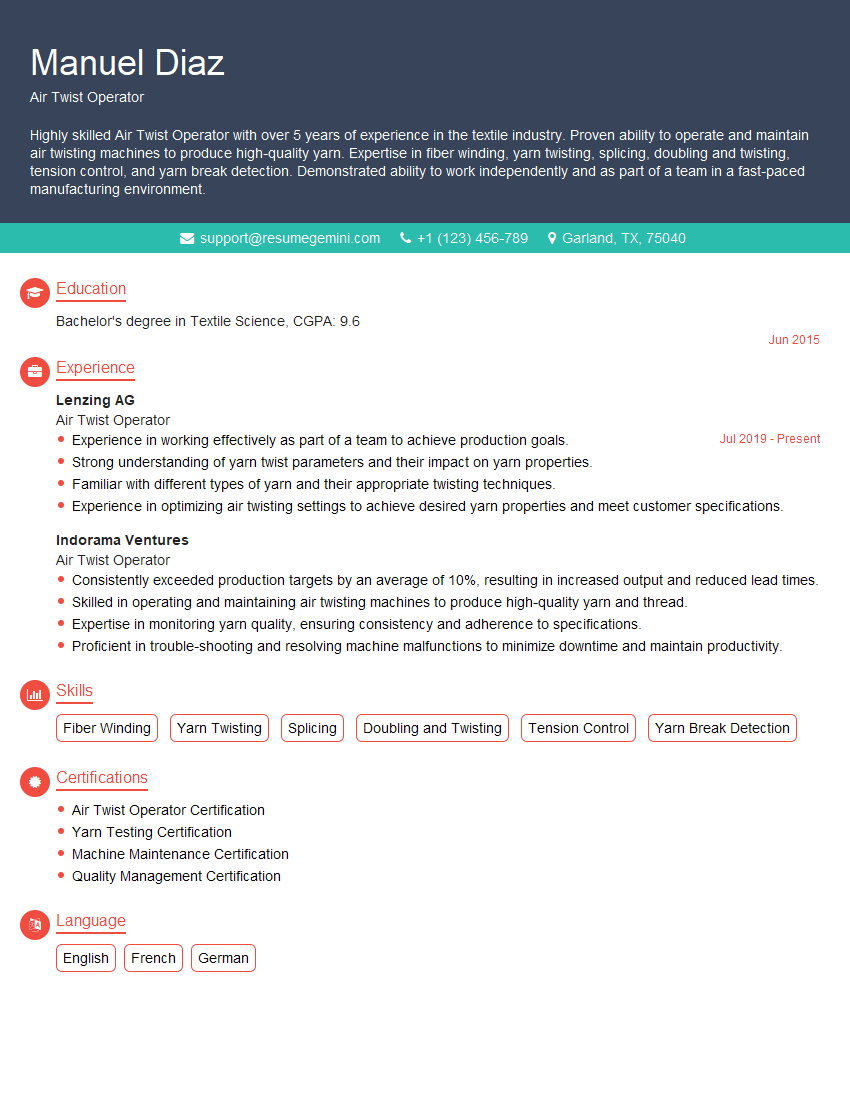

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Twist Operator

1. Explain the process of twist setting in air twist texturing?

The air twist setting process involves several steps:

- Creeling: Empty bobbins or tubes are placed on a creel, and yarn is guided from supply packages onto them.

- Yarn tension control: Tension rollers or sensors monitor and adjust yarn tension to ensure consistent twist.

- Twisting: Air jets are used to induce twist in the yarn. The intensity and direction of airflow determine the twist level.

- Heat setting: The twisted yarn is passed through a heat setting zone, where heat and moisture are applied to stabilize the twist.

- Winding: The twisted and heat-set yarn is wound onto bobbins or packages.

2. Describe the different types of air twisting machines?

Spinning Machines

- Ring spinning

- Open-end spinning

- Rotor spinning

Twisting Machines

- Two-for-one twisting

- False-twist texturing

- Air jet texturing

3. What are the key parameters to control in air twist texturing?

To achieve desired yarn properties, it is crucial to control the following parameters:

- Twist level: The amount of twist imparted to the yarn, measured in twists per inch or meter.

- Twist direction: The direction of twist, either S-twist (right-hand) or Z-twist (left-hand).

- Air pressure: The pressure of the air jets used to induce twist, which affects the twist level.

- Heat setting temperature: The temperature at which the twisted yarn is heat-set to stabilize the twist.

- Yarn tension: The tension maintained throughout the process to prevent yarn breakage and ensure uniform twist.

4. Discuss the troubleshooting techniques for common air twist texturing issues?

Common issues in air twist texturing and their troubleshooting techniques include:

- Yarn breakage: Inspect yarn tension, machine settings, and yarn quality.

- Uneven twist: Check air pressure, heat setting temperature, and machine calibration.

- Yarn hairiness: Adjust air pressure and heat setting conditions.

- Yarn shrinkage: Optimize heat setting parameters and yarn moisture content.

- Yarn discoloration: Examine heat setting temperature and dwell time.

5. Explain the role of air texturing in yarn manufacturing?

Air texturing is a crucial process in yarn manufacturing as it imparts various properties to the yarn:

- Improved bulk: Air texturing increases the yarn’s volume and fullness, giving it a soft and fluffy feel.

- Enhanced wickability: The textured yarn has increased surface area, which promotes moisture absorption and wicking.

- Increased comfort: Textured yarns are more breathable and comfortable to wear, making them ideal for garments and home textiles.

- Aesthetic appeal: Air texturing can create unique yarn effects, such as loops, curls, and slubs, adding visual interest to fabrics.

- Higher fabric elasticity: Textured yarns contribute to fabric elasticity, providing improved stretch and recovery properties.

6. Describe the safety precautions to be observed when operating an air twist texturing machine?

To ensure operator safety, it is essential to adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Keep the work area clean and free of tripping hazards.

- Never attempt to clear jams or make adjustments while the machine is running.

- Report any malfunctions or safety concerns to a supervisor immediately.

- Follow all operating instructions and safety protocols provided by the machine manufacturer.

7. Explain the maintenance procedures for air twist texturing machines?

Regular maintenance is crucial to ensure optimal machine performance and prevent breakdowns:

- Daily checks: Inspect air nozzles, tension devices, and yarn guides for wear or damage.

- Weekly maintenance: Clean and lubricate machine components, check belt tension, and calibrate sensors.

- Monthly inspections: Perform a thorough inspection of all machine parts, including bearings, motors, and electrical connections.

- Scheduled overhauls: Follow the manufacturer’s recommended schedule for major overhauls to replace worn parts and ensure overall machine reliability.

8. What are the quality standards and testing methods used for air textured yarns?

Air textured yarns are subject to various quality standards and testing methods to ensure yarn quality and consistency:

- Yarn count: Measured in tex or denier, yarn count determines the yarn’s thickness.

- Twist level: Measured in twists per inch or meter, twist level affects yarn strength and appearance.

- Yarn strength: Tensile strength and elongation tests assess the yarn’s ability to withstand stress.

- Yarn evenness: Measured using CV% (coefficient of variation), yarn evenness indicates the uniformity of yarn thickness.

- Yarn hairiness: Measured using a hairiness tester, yarn hairiness assesses the presence of loose fibers on the yarn surface.

9. Discuss the environmental considerations associated with air twist texturing?

Air twist texturing involves the use of energy, chemicals, and water, which can have environmental implications:

- Energy consumption: The machines used in air twist texturing consume a significant amount of electricity.

- Chemical usage: Chemicals used in yarn preparation and heat setting can have environmental impacts.

- Water consumption: Water is used for yarn conditioning and heat setting processes.

- Waste generation: Waste materials, such as yarn scraps and packaging, need to be disposed of responsibly.

10. What are the career advancement opportunities for an air twist operator?

With experience and qualifications, an air twist operator can progress in their career:

- Quality control technician: Monitor yarn quality and ensure compliance with standards.

- Production supervisor: Oversee air twist texturing operations and manage staff.

- Process engineer: Develop and optimize air twist texturing processes.

- Technical manager: Lead a team of engineers and technicians in yarn manufacturing.

- Plant manager: Manage a yarn manufacturing facility, including air twist texturing operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Twist Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Twist Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Twist Operators are responsible for producing high-quality yarn through the efficient operation and maintenance of air twist machines. This involves a range of duties related to yarn manufacturing, machine operations, and quality control.

1. Yarn Production and Monitoring

Setting up and operating air twist machines to produce yarn according to specified specifications

- Monitoring yarn quality during production and making adjustments as necessary to ensure compliance with standards

- Conducting regular inspections of yarn to identify and resolve quality issues promptly

2. Machine Operation and Maintenance

Maintaining air twist machines in optimal working condition through regular cleaning, lubrication, and repairs.

- Troubleshooting and resolving machine breakdowns to minimize downtime and ensure efficient production

- Performing preventive maintenance tasks to extend the lifespan of equipment and optimize performance

3. Production Planning and Scheduling

Working closely with production planners to determine yarn production schedules and allocate resources effectively

- Estimating production capacity and adjusting schedules to meet customer demand

- Coordinating with other departments to ensure a smooth and efficient production process

4. Quality Control and Assurance

Ensuring that all produced yarn meets the required quality standards and customer specifications

- Conducting in-process and final inspections to identify and rectify any defects

- Documenting and reporting on quality control measures to maintain transparency and accountability

Interview Tips

To ace an Air Twist Operator interview, it is important to prepare thoroughly and demonstrate your skills and knowledge in yarn production, machine operation, and quality control. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company, its products, and the specific role you are applying for. This will help you understand the company’s culture and the requirements of the position.

- Visit the company’s website and social media pages to learn about their mission, values, and recent projects.

- Read industry news and articles to stay up-to-date on the latest trends and technologies in yarn manufacturing.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications for the role. Practice answering these questions clearly and concisely, highlighting your strengths and relevant accomplishments.

- Describe your experience in operating and maintaining air twist machines.

- How do you ensure that the produced yarn meets the required quality standards?

- Provide an example of how you resolved a complex machine issue and minimized downtime.

3. Highlight Your Technical Skills and Knowledge

Emphasize your technical skills and knowledge in yarn manufacturing and air twist machine operation. Discuss your understanding of yarn properties, machine components, and quality control techniques.

- Explain how you use your knowledge of yarn twisting parameters to optimize production efficiency.

- Describe your experience in troubleshooting and repairing air twist machines.

- Explain your understanding of quality control procedures and how you ensure compliance with industry standards.

4. Demonstrate Your Attention to Detail and Problem-Solving Abilities

Air Twist Operators need to be meticulous and detail-oriented. Highlight your ability to identify and resolve issues promptly, and your commitment to maintaining a clean and organized work area.

- Provide examples of how you have identified and corrected quality defects in yarn production.

- Explain how you prioritize tasks and manage your time effectively to meet production deadlines.

- Discuss your approach to problem-solving and how you remain calm under pressure.

5. Be Enthusiastic and Show Your Passion for the Role

Convey your enthusiasm for the role and your passion for yarn manufacturing. Express your interest in contributing to the company’s success and your commitment to producing high-quality yarn.

- Share your knowledge of the industry and your eagerness to learn new techniques.

- Explain why you are interested in working for this specific company and how your skills align with their needs.

- Ask thoughtful questions to demonstrate your engagement and interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Air Twist Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.