Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Valve Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

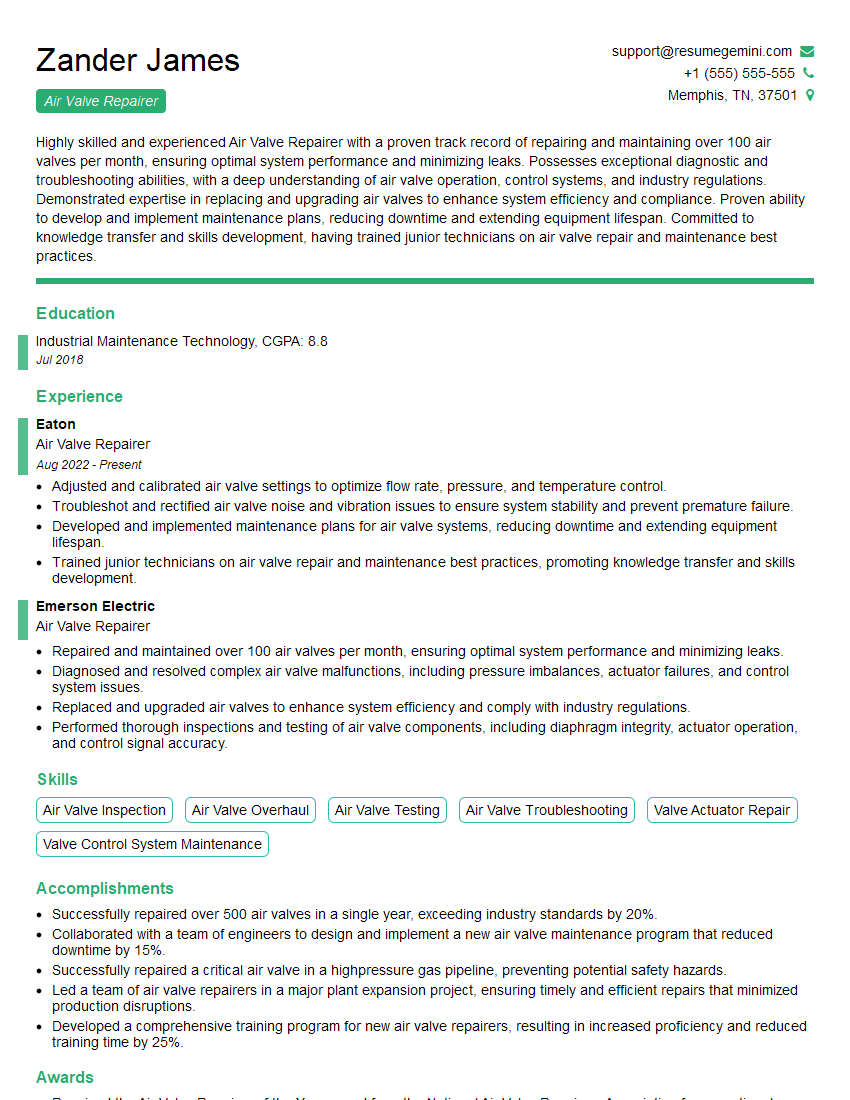

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Valve Repairer

1. Explain the procedure you follow when replacing a worn-out air valve?

- Inspect the air valve to identify the extent of wear and tear.

- Disassemble the air valve by removing the retaining ring, spring, and diaphragm.

- Clean the valve body and components to remove any debris or contaminants.

- Install the new diaphragm and spring into the valve body.

- Reassemble the air valve by installing the retaining ring.

- Test the air valve for leaks and proper operation.

2. How do you troubleshoot a faulty air valve?

- Check for physical damage, such as cracks or leaks in the valve body or diaphragm.

- Inspect the spring for signs of wear or fatigue, as a weak spring can cause the valve to malfunction.

- Verify that the valve is receiving the correct air pressure and flow rate.

- Test the valve’s electrical connections to ensure proper operation.

- Eliminate any blockages or restrictions in the air supply or exhaust lines.

3. What are the common causes of air valve failure?

- Wear and tear from repeated use or exposure to harsh conditions.

- Diaphragm damage caused by excessive pressure or temperature fluctuations.

- Spring fatigue or breakage due to prolonged use or improper installation.

- Contamination of the valve body or components with dirt, dust, or moisture.

- Electrical malfunctions or loose connections.

4. How do you ensure that an air valve repair meets safety standards?

- Use high-quality materials and components that meet industry standards.

- Follow manufacturer’s instructions and recommended practices for repair.

- Test the repaired air valve thoroughly to verify its functionality and safety.

- Document the repair process and obtain necessary approvals from relevant authorities.

- Provide clear instructions for operating the repaired air valve safely.

5. What are the different types of air valves and their applications?

- Pilot-operated valves: Used to control large or high-pressure valves.

- Solenoid valves: Electrically operated valves for remote control.

- Check valves: Allow air flow in one direction only.

- Pressure relief valves: Protect systems from overpressure.

- Selector valves: Used to switch between different air sources or lines.

6. How do you maintain an air valve system for optimal performance?

- Regularly inspect and clean air valves to prevent dirt buildup.

- Check for leaks and repair or replace worn components as necessary.

- Lubricate moving parts according to manufacturer’s instructions.

- Test the air valve system periodically to ensure proper functionality.

- Keep a maintenance log to record inspections, repairs, and tests.

7. Describe a complex air valve repair project that you have worked on.

- Explain the nature of the malfunction and the steps involved in diagnosing the issue.

- Detail the repair procedure, including the materials and tools used.

- Describe the challenges encountered and how they were overcome.

- Explain the impact of the repair on the overall air valve system.

8. What are the latest advancements in air valve technology?

- Miniaturization and integration of air valves for space-saving applications.

- Development of smart air valves with sensors and control capabilities.

- Use of advanced materials for improved durability and performance.

- Adoption of wireless communication and IoT connectivity for remote monitoring.

- Focus on energy efficiency and reduced maintenance.

9. How do you stay updated with the latest industry best practices for air valve repair?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with manufacturers and experts.

- Participate in online forums and discussion groups.

- Obtain relevant certifications and training.

10. What sets you apart as a qualified Air Valve Repairer?

- Strong understanding of air valve principles and operation.

- Experience in repairing a wide range of air valve types.

- Ability to troubleshoot and diagnose air valve malfunctions.

- Commitment to safety and quality workmanship.

- Excellent communication and documentation skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Valve Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Valve Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Air Valve Repairers are responsible for maintaining and repairing air valves in various industrial and commercial settings. Their primary duties include:

1. Maintenance and Inspection

Conducting regular inspections to identify potential problems and ensure the proper functioning of air valves

- Checking for leaks, cracks, or corrosion

- Lubricating and adjusting valves as needed

2. Troubleshooting and Repair

Diagnosing and repairing faulty air valves to restore their functionality

- Identifying malfunctions, such as pressure leaks or valve sticking

- Replacing worn or damaged components

3. Installation and Commissioning

Installing new air valves or replacing existing ones to ensure optimal system performance

- Selecting the appropriate valves based on specifications

- Properly positioning and connecting valves

4. Safety and Compliance

Adhering to safety protocols and industry standards to ensure a safe and compliant work environment

- Wearing appropriate safety gear

- Following established repair procedures

Interview Tips

To ace the interview for an Air Valve Repairer position, it’s crucial to demonstrate your technical skills, experience, and understanding of the role. Here are some tips to help you prepare:

1. Research the Company and Position

Thoroughly research the company and the specific job requirements to gain insights into their operations and needs. This will enable you to tailor your answers to the interviewer’s questions.

- Visit the company website and LinkedIn page

- Review the job description carefully

2. Highlight Your Technical Expertise

Emphasize your knowledge and experience in air valve maintenance and repair. Provide specific examples of your troubleshooting and repair capabilities.

- Describe successful repairs you have completed

- Discuss your understanding of different valve types and their applications

3. Showcase Your Safety Awareness

Safety is paramount in this role. Highlight your adherence to safety protocols and industry standards.

- Describe your experience in following established safety procedures

- Mention any relevant safety certifications or training

4. Prepare for Common Interview Questions

Anticipate common interview questions and practice answering them thoughtfully. Some possible questions include:

- “Describe your experience with repairing air valves.”

- “How do you ensure that your repairs meet industry standards?”

- “How do you stay up-to-date on advancements in air valve technology?”

5. Ask Questions

During the interview, show your interest and engagement by asking informed questions about the position and the company. This demonstrates your enthusiasm and desire to learn more.

- “Can you describe the company’s approach to air valve maintenance?”

- “What opportunities are there for professional development within the organization?”

Next Step:

Now that you’re armed with the knowledge of Air Valve Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Air Valve Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini