Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft Cylinder Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

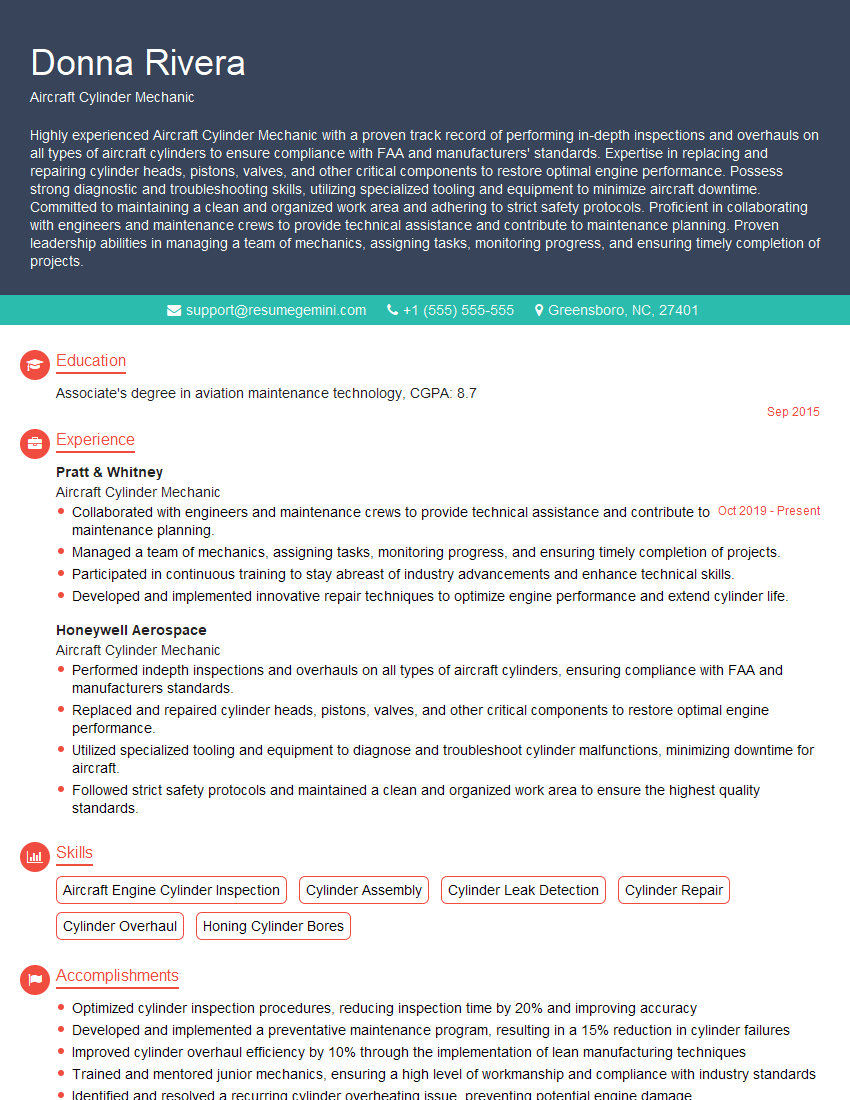

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Cylinder Mechanic

1. What are the main responsibilities of an Aircraft Cylinder Mechanic?

- Inspect, repair, and overhaul aircraft engine cylinders, cylinder heads, and related components.

- Troubleshoot and diagnose cylinder malfunctions using specialized tools and equipment.

- Balance and align cylinders to ensure proper engine operation.

- Maintain a clean and organized work area and adhere to safety protocols.

2. Describe the process of honing an aircraft engine cylinder.

Inspection

- Inspect the cylinder for any damage or wear.

- Measure the cylinder bore to determine the amount of material to be removed.

Honing Process

- Select the appropriate honing stone and abrasive grit based on the cylinder material.

- Align the honing tool with the cylinder bore and start the honing process.

- Maintain consistent pressure and speed throughout the honing process.

Measuring and Inspection

- Periodically measure the cylinder bore to ensure accuracy.

- Inspect the cylinder after honing to ensure a smooth and uniform surface finish.

3. What are the different types of cylinder heads used in aircraft engines?

- Radial: Used in older radial engines, with cylinders arranged around a central crankshaft.

- Inline: Used in inline engines, with cylinders arranged in a row along the crankshaft.

- Vee: Used in V-type engines, with cylinders arranged in two banks forming a V-shape.

- Opposed: Used in opposed engines, with cylinders arranged horizontally opposite each other.

4. Explain the importance of valve timing in an aircraft engine.

- Ensures the proper opening and closing of intake and exhaust valves.

- Maximizes engine performance by controlling the flow of air and fuel.

- Prevents engine damage by preventing valve interference with the piston.

5. Describe the steps involved in replacing a cylinder head gasket.

Preparation

- Remove all accessories and hoses connected to the cylinder head.

- Remove the valve cover and inspect the valve train.

- Drain the coolant and oil from the engine.

Gasket Removal

- Carefully remove the old cylinder head gasket.

- Inspect the gasket and cylinder head surfaces for any damage or wear.

Gasket Installation

- Clean the gasket surfaces and apply a sealant.

- Position the new cylinder head gasket correctly.

- Apply torque to the cylinder head bolts in the correct sequence.

6. How do you troubleshoot a loss of compression in an aircraft engine cylinder?

- Valves: Check for worn or damaged valves, valve seats, or valve springs.

- Piston Rings: Check for broken or worn piston rings, which can cause compression leaks.

- Cylinder Walls: Inspect the cylinder walls for scoring, scratches, or excessive wear.

- Head Gasket: Examine the head gasket for signs of damage or leaks.

7. What are the safety precautions that must be taken when working on aircraft engine cylinders?

- Wear appropriate personal protective equipment (PPE).

- Follow all manufacturer’s instructions and maintenance procedures.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Use proper lifting techniques to prevent injuries.

- Keep the work area clean and free of debris.

8. How do you ensure the accuracy and quality of your work?

- Follow all established procedures and specifications.

- Use precision tools and equipment and calibrate them regularly.

- Double-check all measurements and calculations.

- Seek assistance from experienced mechanics or supervisors when needed.

- Document all work performed and maintain accurate records.

9. What are some common challenges you face as an Aircraft Cylinder Mechanic and how do you overcome them?

- Tight deadlines: Prioritizing tasks and managing time effectively.

- Complex repairs: Consulting technical manuals, seeking advice from experts, and using specialized tools.

- Safety concerns: Adhering to safety protocols, using proper PPE, and maintaining a clean work environment.

10. How do you stay updated with the latest advancements in aircraft engine technology?

- Attend industry conferences and workshops.

- Read technical publications and journals.

- Participate in online forums and discussions.

- Seek guidance from experienced mechanics and engineers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Cylinder Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Cylinder Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Cylinder Mechanics play a critical role in maintaining and ensuring the safety of aircraft engines. Their responsibilities include:

1. Inspection and Maintenance

Inspecting and servicing aircraft cylinders, cylinder heads, and related components.

- Performing leak tests and compression checks to identify any potential issues.

- Measuring clearances and tolerances to ensure proper fit and operation.

2. Repair and Overhaul

Repairing or overhauling damaged or worn cylinders, including welding, grinding, and plating.

- Replacing piston rings, valves, and other internal components.

- Reassembling and testing cylinders to meet specifications.

3. Troubleshooting and Diagnostics

Diagnosing and troubleshooting engine problems related to cylinders.

- Analyzing cylinder performance data and identifying potential causes of failures.

- Performing non-destructive testing, such as boroscoping, to inspect internal components.

4. Documentation and Reporting

Maintaining detailed records of all inspections, repairs, and overhauls.

- Preparing technical reports and documentation for regulatory compliance.

- Communicating with pilots and engineers regarding cylinder status and potential issues.

Interview Tips

To ace an interview for an Aircraft Cylinder Mechanic position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company, its products or services, and the specific role you are applying for. This will demonstrate your interest and help you tailor your answers accordingly.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into the company’s operations.

2. Practice Your Answers

Prepare and practice your answers to common interview questions. This will help you feel more confident and articulate during the interview.

- Prepare an elevator pitch that highlights your skills, experience, and why you are interested in the role.

- Brainstorm examples of your past experiences that demonstrate your technical abilities.

3. Showcase Your Technical Skills

Emphasize your technical skills and knowledge in your answers. Highlight your experience in inspecting, repairing, and overhauling aircraft cylinders.

- Provide specific examples of projects you have worked on.

- Quantify your accomplishments whenever possible, such as reducing downtime or improving engine performance.

4. Display Your Safety Mindset

Aircraft Cylinder Mechanics play a crucial role in ensuring the safety of aircraft. Emphasize your safety-conscious mindset and attention to detail in your answers.

- Describe your understanding of safety regulations and industry standards.

- Explain how you prioritize safety in your work and how you would handle potential safety concerns.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to show your engagement and interest. This also gives you an opportunity to gather more information about the company and role.

- Ask about the company’s training and development opportunities.

- Inquire about the company’s safety record and procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Aircraft Cylinder Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Aircraft Cylinder Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.