Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft De-Icer Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

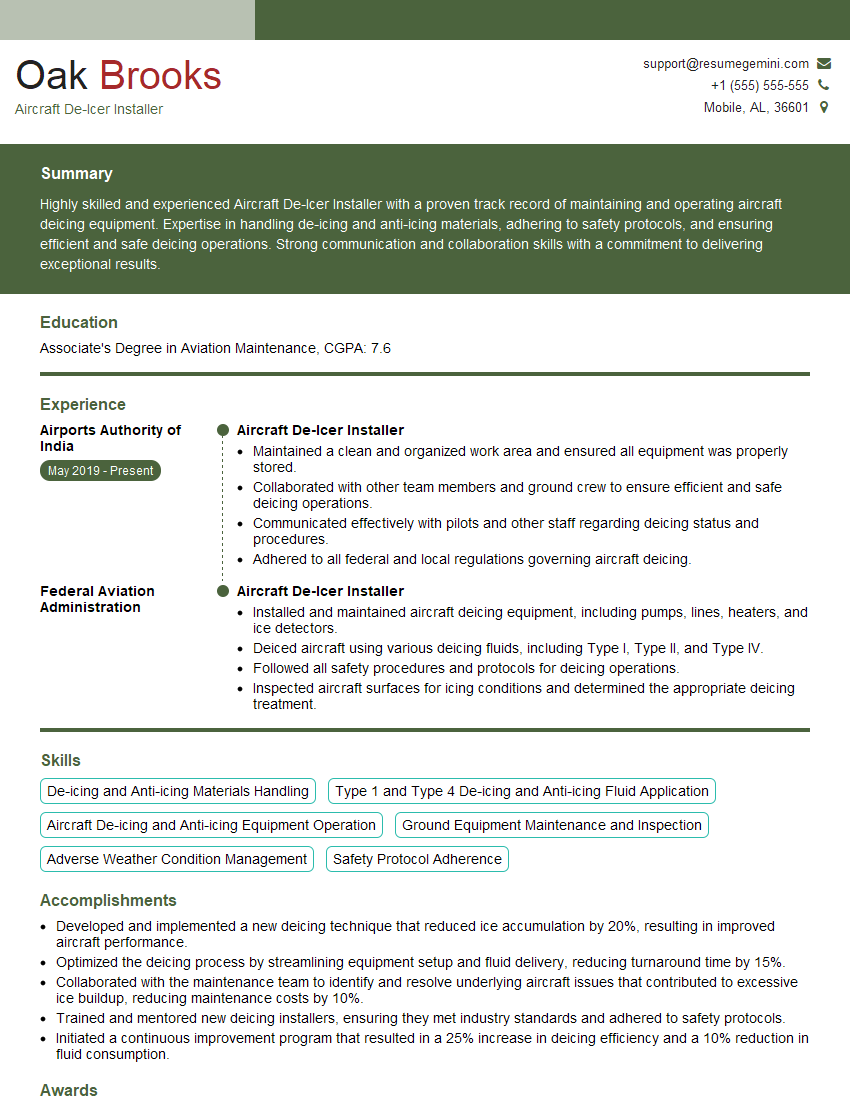

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft De-Icer Installer

1. What are the different types of aircraft de-icing fluids?

- Type I: These fluids are primarily composed of propylene glycol and are used in non-freezing conditions.

- Type II: These fluids contain a higher concentration of propylene glycol and are used in light icing conditions.

- Type III: These fluids are made with a blend of propylene glycol and ethylene glycol and are used in moderate to severe icing conditions.

- Type IV: These fluids are composed of formamide and are designed for use in extreme icing conditions.

2. What are the safety precautions that must be observed when handling and applying de-icing fluids?

Personal Protective Equipment (PPE)

- Wear chemical-resistant gloves, eye protection, and a respirator.

- Avoid skin contact with de-icing fluids.

- Handle fluids in well-ventilated areas.

Equipment Handling

- Ensure that the de-icing equipment is properly maintained and calibrated.

- Follow manufacturer’s instructions for the safe operation of the equipment.

- Use proper grounding techniques to prevent static electricity buildup.

3. What are the different methods of aircraft de-icing?

- Manual De-icing: This involves physically removing ice and snow from the aircraft using brushes, scrapers, and brooms.

- Chemical De-icing: This method involves spraying de-icing fluids onto the aircraft surface to dissolve and prevent ice formation.

- Thermal De-icing: This method uses heated air or infrared radiation to melt ice and snow from the aircraft.

4. What factors influence the selection of the appropriate de-icing method?

- Aircraft Type: Different aircraft have specific de-icing requirements based on their design and materials.

- Level of Icing: The severity and extent of ice accumulation determine the appropriate de-icing method.

- Environmental Conditions: Temperature, humidity, and wind speed can affect the effectiveness of de-icing fluids and methods.

- Available Resources: The availability of de-icing equipment, fluids, and personnel influence the choice of method.

5. Describe the steps involved in the manual de-icing of an aircraft.

- Inspect the aircraft for ice and snow accumulation.

- Select the appropriate de-icing tools and equipment.

- Safely approach the aircraft and begin removing ice and snow from the wings, tail, and fuselage.

- Ensure that all ice and snow is completely removed, including from the control surfaces and pitot tubes.

- Inspect the aircraft again to verify that no ice or snow remains.

6. How do you ensure the proper application of chemical de-icing fluids?

- Follow the manufacturer’s instructions for the specific fluid being used.

- Use the proper dilution ratio and temperature for the fluid.

- Apply the fluid evenly over the entire aircraft surface, including the wings, tail, and fuselage.

- Allow the fluid sufficient time to dwell on the aircraft to effectively dissolve and prevent ice formation.

- Inspect the aircraft to ensure complete coverage and effectiveness of the fluid application.

7. What are the potential hazards associated with the use of chemical de-icing fluids?

- Chemical exposure to personnel handling and applying the fluids.

- Environmental impact on soil, water, and wildlife.

- Corrosion of aircraft components and infrastructure.

- Fire hazard due to the flammability of some de-icing fluids.

8. How do you inspect an aircraft after de-icing to ensure that it is safe for flight?

- Check for any remaining ice or snow accumulation.

- Inspect the aircraft’s control surfaces, pitot tubes, and other critical areas for proper movement and functionality.

- Review the de-icing fluid application to ensure complete coverage and effectiveness.

- Consult with the aircraft manufacturer’s guidelines for specific inspection criteria.

9. What are the maintenance and calibration requirements for aircraft de-icing equipment?

- Regular inspection and testing of the equipment.

- Calibration of the fluid application system to ensure accurate and consistent dispensing.

- Maintenance of electrical and mechanical components to ensure reliable operation.

- Compliance with manufacturer’s maintenance and calibration schedules.

10. How do you stay updated on the latest developments and best practices in aircraft de-icing?

- Attend industry conferences and workshops.

- Read technical publications and articles.

- Consult with aircraft manufacturers and de-icing fluid suppliers.

- Participate in ongoing training and certification programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft De-Icer Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft De-Icer Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft De-Icer Installers play a crucial role in ensuring the safety of aircraft during winter weather conditions. Their primary responsibilities include:

1. De-icing and Anti-icing Aircraft

De-icing involves removing ice and snow from aircraft surfaces, while anti-icing prevents ice formation. Installers use specialized equipment, such as de-icing trucks and sprayers, to apply de-icing and anti-icing fluids onto the aircraft.

- Operate de-icing and anti-icing equipment to remove or prevent ice formation on aircraft surfaces

- Follow established procedures and safety guidelines during de-icing and anti-icing operations

2. Inspecting Aircraft Surfaces

Installers inspect aircraft surfaces before and after de-icing and anti-icing to ensure that the aircraft is free of ice and snow and that the fluids are applied correctly.

- Visually inspect aircraft surfaces for ice, snow, or other contaminants

- Identify and report any damage or defects to aircraft surfaces

3. Monitoring Weather Conditions

Installers monitor weather conditions and make decisions on the appropriate de-icing and anti-icing measures to take based on the temperature, precipitation, and other factors.

- Monitor weather conditions and forecasts to determine appropriate de-icing and anti-icing measures

- Communicate with pilots and other ground personnel to coordinate de-icing and anti-icing operations

4. Maintaining Equipment

Installers maintain and calibrate de-icing and anti-icing equipment to ensure optimal performance and safety.

- Inspect and maintain de-icing and anti-icing equipment regularly

- Calibrate equipment to ensure accurate application of de-icing and anti-icing fluids

Interview Tips

Preparing for an Aircraft De-Icer Installer interview requires a combination of technical knowledge and situational awareness. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and current projects. Research the specific role and its responsibilities to demonstrate your understanding of the position.

- Visit the company’s website and social media pages

- Read industry news and articles about the company and the aviation sector

2. Highlight Your Technical Skills

Emphasize your experience and proficiency in operating de-icing and anti-icing equipment. Mention any certifications or training you have received in these areas.

- Provide specific examples of your experience de-icing and anti-icing aircraft

- Explain how you ensure the accuracy and effectiveness of your de-icing and anti-icing applications

3. Demonstrate Your Safety Awareness

Safety is paramount in aircraft de-icing operations. Showcase your understanding of safety procedures, regulations, and emergency protocols.

- Describe your knowledge of de-icing and anti-icing safety guidelines

- Explain how you prioritize safety in your work and communicate potential hazards

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your qualifications. Practice answering questions about your experience, skills, and motivation.

- Tell me about a time you had to make a quick decision in a fast-paced de-icing operation

- How do you handle working in extreme weather conditions?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft De-Icer Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.