Feeling lost in a sea of interview questions? Landed that dream interview for Aircraft Engine Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aircraft Engine Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

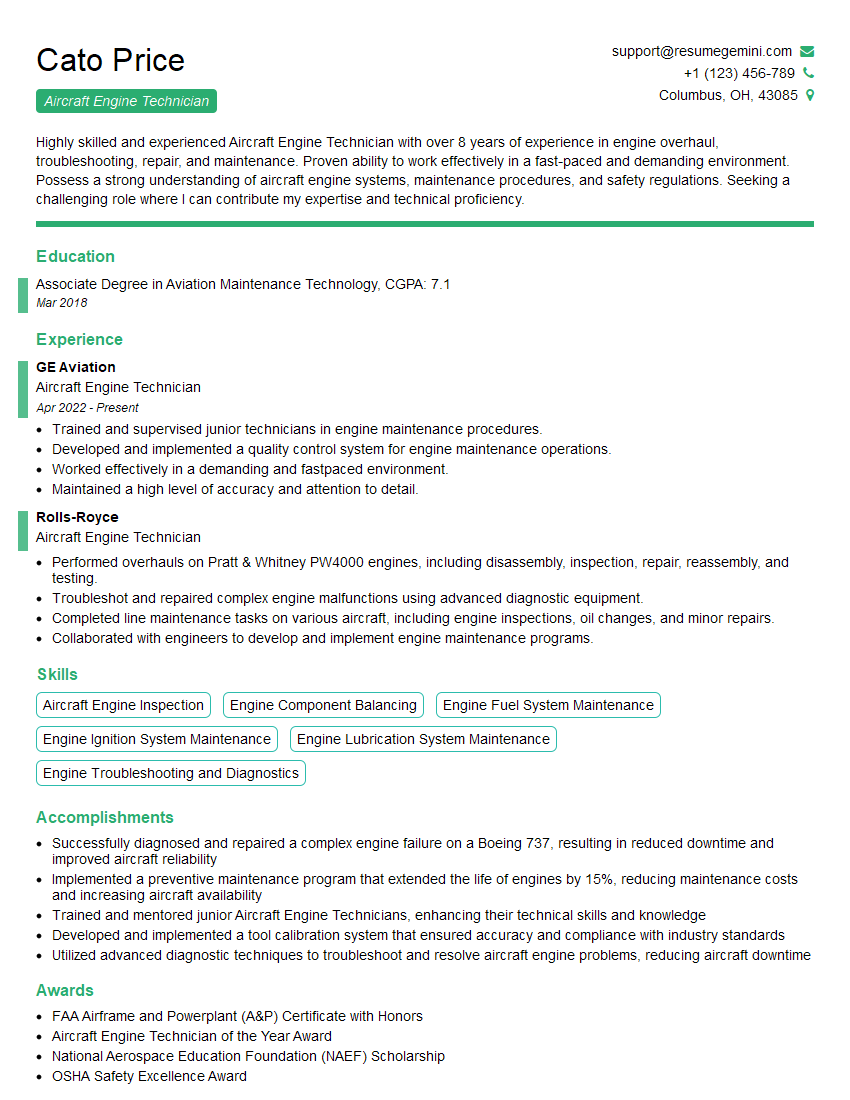

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Engine Technician

1. What is the difference between a dry sump and a wet sump lubrication system?

- In a dry sump lubrication system, the oil is stored in a separate tank and is pumped to the engine by an oil pump. In a wet sump lubrication system, the oil is stored in the engine’s oil pan and is splashed onto the engine’s components by the crankshaft.

- Dry sump lubrication systems are more efficient than wet sump lubrication systems because they can scavenge oil from the engine more effectively. This can help to reduce oil consumption and improve engine performance.

- Wet sump lubrication systems are less expensive to manufacture than dry sump lubrication systems. They are also easier to maintain because the oil is not stored in a separate tank.

2. What is the purpose of the bleed air system?

subheading of the answer

- The bleed air system provides air to the aircraft’s air conditioning system, pressurization system, and anti-ice system.

subheading of the answer

- The bleed air system is supplied by air from the engine’s compressors. This air is then passed through a heat exchanger to cool it before it is distributed to the aircraft’s systems.

- The bleed air system is an important part of the aircraft’s environmental control system. It helps to provide a comfortable and safe environment for the aircraft’s occupants.

3. What is the difference between a turbine and a compressor?

- A turbine is a rotary engine that converts the energy of a moving fluid into mechanical energy. A compressor is a rotary machine that converts the energy of a rotating shaft into the energy of a compressed fluid.

- Turbines are used in a variety of applications, including aircraft engines, power plants, and industrial machinery. Compressors are used in a variety of applications, including air conditioning systems, refrigeration systems, and industrial processes.

- The main difference between a turbine and a compressor is the direction of energy flow. In a turbine, the energy flows from the fluid to the shaft. In a compressor, the energy flows from the shaft to the fluid.

4. What are the different types of aircraft engine controls?

- There are two main types of aircraft engine controls: manual controls and automatic controls.

- Manual controls are used to control the engine’s power output, speed, and fuel flow. Automatic controls are used to maintain the engine’s desired operating conditions.

- Manual controls are typically used during takeoff, landing, and other critical phases of flight. Automatic controls are typically used during cruise flight.

5. What are the different types of aircraft engine instruments?

- There are a variety of aircraft engine instruments that are used to monitor the engine’s performance and operating conditions.

- The most common engine instruments include the tachometer, which measures the engine’s speed; the fuel flow indicator, which measures the amount of fuel being consumed by the engine; the oil pressure gauge, which measures the pressure of the oil in the engine; and the oil temperature gauge, which measures the temperature of the oil in the engine.

- Other engine instruments include the exhaust gas temperature gauge, which measures the temperature of the exhaust gases leaving the engine; the manifold pressure gauge, which measures the pressure of the air in the engine’s intake manifold; and the turbocharger boost gauge, which measures the pressure of the air being supplied to the engine by the turbocharger.

6. What are the different types of aircraft engine maintenance?

- There are three main types of aircraft engine maintenance: scheduled maintenance, unscheduled maintenance, and overhaul.

- Scheduled maintenance is performed on a regular basis to prevent problems from developing. Unscheduled maintenance is performed to repair problems that have already occurred. Overhaul is a major maintenance procedure that is performed to restore the engine to its original condition.

- Scheduled maintenance is typically performed every 50-100 flight hours. Unscheduled maintenance is performed as needed. Overhaul is typically performed every 2,000-4,000 flight hours.

7. What are the different types of aircraft engine failures?

- There are a variety of different types of aircraft engine failures that can occur.

- Some of the most common types of aircraft engine failures include: loss of power, engine fires, and engine explosions.

- Loss of power can be caused by a variety of factors, including fuel problems, air problems, and mechanical problems.

- Engine fires can be caused by a variety of factors, including leaks, electrical problems, and overheated components.

- Engine explosions can be caused by a variety of factors, including detonation, backfires, and overheating.

8. What are the different types of aircraft engine repairs?

- There are a variety of different types of aircraft engine repairs that can be performed.

- Some of the most common types of aircraft engine repairs include: replacing spark plugs, replacing fuel filters, and replacing oil filters.

- Other types of aircraft engine repairs include: repairing leaks, replacing sensors, and repairing wiring.

- The type of aircraft engine repair that is needed will depend on the specific problem that is occurring.

9. What are the different types of aircraft engine inspections?

- There are a variety of different types of aircraft engine inspections that can be performed.

- Some of the most common types of aircraft engine inspections include: visual inspections, borescope inspections, and ultrasonic inspections.

- Visual inspections are used to look for cracks, corrosion, and other visible damage to the engine.

- Borescope inspections are used to look inside the engine for damage that is not visible to the naked eye.

- Ultrasonic inspections are used to look for cracks and other defects in the engine using sound waves.

10. What are the different types of aircraft engine tests?

- There are a variety of different types of aircraft engine tests that can be performed.

- Some of the most common types of aircraft engine tests include: run-up tests, power tests, and endurance tests.

- Run-up tests are used to check the engine’s starting system, fuel system, and ignition system.

- Power tests are used to measure the engine’s power output and specific fuel consumption.

- Endurance tests are used to check the engine’s ability to run for long periods of time without failing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Engine Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Engine Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Engine Technicians are responsible for the maintenance and repair of aircraft engines. They work on a variety of aircraft, including commercial airliners, private jets, and military aircraft. Their duties include:

1. Inspecting and diagnosing engine problems

Aircraft Engine Technicians use a variety of tools and techniques to inspect and diagnose engine problems. They may use visual inspections, borescopes, and other tools to look for signs of wear, damage, or other problems. They may also use diagnostic software to analyze engine data and identify potential issues.

2. Removing and replacing engines

When an engine needs to be replaced, Aircraft Engine Technicians remove the old engine and install a new one. This is a complex process that requires a great deal of skill and experience. Technicians must be able to work quickly and efficiently to minimize downtime for the aircraft.

3. Performing engine overhauls

Engine overhauls are major maintenance events that involve disassembling the entire engine and inspecting and repairing all of its components. Aircraft Engine Technicians must be able to work independently and follow detailed procedures to ensure that the overhaul is performed correctly.

4. Maintaining engine records

Aircraft Engine Technicians are responsible for maintaining detailed records of all maintenance and repairs performed on engines. These records are used to track the history of the engine and to ensure that it is operating safely and efficiently.

Interview Tips

Preparing for an interview for an Aircraft Engine Technician position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Aircraft Engine Technician. Be prepared to talk about your education, training, and any relevant work experience. You should also be able to discuss your skills in detail, such as your ability to inspect and diagnose engine problems, remove and replace engines, and perform engine overhauls.

4. Be prepared to ask questions

At the end of the interview, you will likely be given the opportunity to ask questions. This is a good chance to show the interviewer that you are interested in the position and that you have done your research. Some good questions to ask include: “What is the company’s culture like?” “What are the biggest challenges facing the company?” and “What are the opportunities for advancement?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Engine Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!