Are you gearing up for an interview for a Aircraft Instrument Tester position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Aircraft Instrument Tester and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

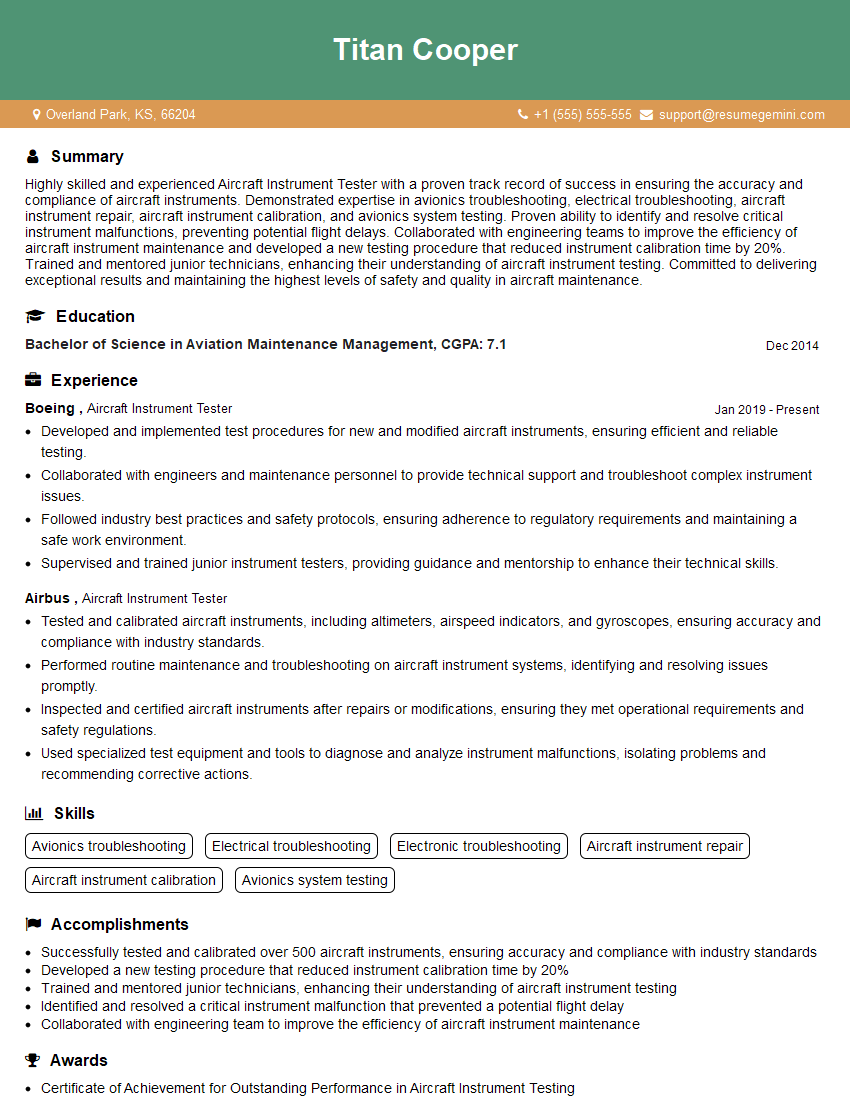

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Instrument Tester

1. Explain the primary responsibility of an Aircraft Instrument Tester?

As an Aircraft Instrument Tester, I am responsible for testing and calibrating aircraft instruments to ensure their accuracy and reliability. This includes testing instruments such as altimeters, airspeed indicators, gyroscopes, and other critical components.

2. Describe the various testing procedures used for an aircraft attitude indicator?

Static testing

- Confirming the instrument’s zero position

- Checking the instrument’s scale accuracy

Dynamic testing

- Simulating flight conditions using a rate table

- Evaluating the instrument’s response to various maneuvers

3. Explain the role of industry standards and regulations in aircraft instrument testing?

Industry standards and regulations, such as those from the Federal Aviation Administration (FAA), provide guidelines for testing procedures and ensure that aircraft instruments meet safety and performance requirements. These standards specify the acceptable range of errors, testing methodologies, and documentation procedures.

4. Describe the principles of operation for a pitot-static system?

- The pitot tube measures dynamic (ram) pressure, which is proportional to airspeed

- The static port measures static pressure, which is the ambient air pressure

- The difference between the ram and static pressures provides the airspeed indication

5. How do you troubleshoot common issues with a digital air data computer (ADC)?

- Verifying power supply and connections

- Running diagnostic tests to identify specific error codes

- Inspecting sensors, wiring, and other components for damage or malfunctions

- Replacing faulty components as necessary

6. Describe the importance of calibration in aircraft instrument testing?

Calibration ensures that aircraft instruments provide accurate and reliable readings. It involves adjusting the instrument’s internal parameters to match known standards and verifying its performance against specified limits.

7. How do you maintain and document testing equipment used in aircraft instrument testing?

Maintaining testing equipment involves regular inspection, maintenance, and calibration. Documentation includes recording test results, equipment maintenance records, and calibration certificates to ensure traceability and quality control.

8. How do you interpret and analyze test data to identify potential issues with aircraft instruments?

- Comparing test results to established limits and specifications

- Identifying deviations or discrepancies in data patterns

- Drawing conclusions about the instrument’s performance and potential issues

- Recommending corrective actions or further troubleshooting

9. What safety precautions should be taken when working with aircraft instruments?

- Following established safety protocols and procedures

- Wearing appropriate protective gear

- Discharging static electricity before handling instruments

- Using proper tools and handling techniques

10. How do you stay up-to-date on industry best practices and advancements in aircraft instrument testing?

- Attending industry conferences and webinars

- Reading technical manuals and publications

- Participating in training programs and certifications

- Networking with colleagues and industry experts

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Instrument Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Instrument Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Instrument Testers play a vital role in ensuring the safety and reliability of aircraft systems. Their responsibilities encompass a wide range of tasks, including:

1. Testing and Calibration

Conduct comprehensive testing and calibration of aircraft instruments, including altimeters, airspeed indicators, gyroscopes, and flight control systems.

- Adhere to strict aviation regulations and industry standards.

- Utilize specialized equipment and test procedures to verify instrument accuracy and performance.

- Document test results, identify discrepancies, and recommend corrective actions.

2. Troubleshooting and Repair

Diagnose and resolve instrument malfunctions and failures using troubleshooting techniques.

- Analyze data, interpret fault codes, and determine the root cause of issues.

- Perform repairs, replacements, and adjustments as necessary.

- Ensure that repaired instruments meet safety and performance specifications.

3. Maintenance and Inspection

Conduct regular maintenance and inspections of aircraft instruments to ensure their ongoing functionality.

- Clean, lubricate, and adjust instruments to extend their lifespan.

- Identify potential issues and schedule preventive maintenance.

- Maintain accurate maintenance records and technical logs.

4. Quality Assurance

Implement and maintain quality control procedures to ensure the accuracy and reliability of aircraft instruments.

- Develop and review test plans and protocols.

- Supervise and train junior technicians.

- Participate in audits and inspections to ensure compliance with standards.

Interview Tips

Preparing thoroughly for your Aircraft Instrument Tester interview will enhance your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s business, its products or services, and its reputation in the aviation industry.

- Research the latest trends and developments in aircraft instrument technology.

- Identify the company’s key competitors and understand their market position.

2. Highlight Your Technical Expertise

Emphasize your knowledge of aircraft instrument systems, testing procedures, and troubleshooting techniques.

- Quantify your experience with specific examples of projects or assignments.

- Mention any certifications or licenses that you hold.

3. Showcase Your Problem-Solving Skills

Provide examples of how you have successfully diagnosed and resolved complex instrument issues.

- Describe situations where you had to think critically and apply your technical expertise.

- Highlight your ability to work under pressure and meet deadlines.

4. Emphasize Your Attention to Detail

Aircraft Instrument Testers must be highly detail-oriented and precise.

- Provide examples of how you have consistently achieved accuracy in your work.

- Explain your understanding of the importance of thorough testing and documentation.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the position and the company.

- Inquire about the company’s specific testing procedures and equipment.

- Ask about the opportunities for professional development and career advancement.

Next Step:

Now that you’re armed with the knowledge of Aircraft Instrument Tester interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Aircraft Instrument Tester positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini