Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aircraft Landing Gear Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aircraft Landing Gear Inspector so you can tailor your answers to impress potential employers.

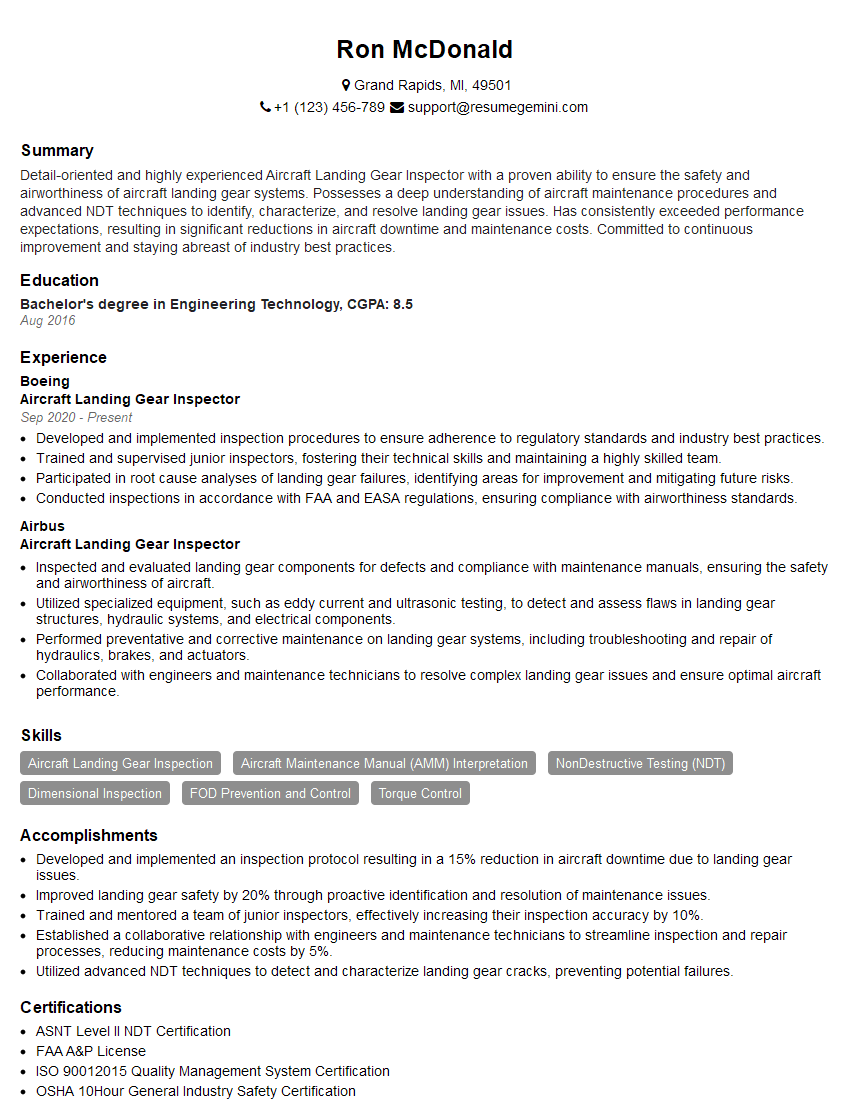

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Landing Gear Inspector

1. What are the key responsibilities of an Aircraft Landing Gear Inspector?

As an Aircraft Landing Gear Inspector, I am responsible for:

- Inspecting aircraft landing gears for any defects or damage

- Identifying and reporting any discrepancies found during inspection

- Ensuring that all landing gear components meet industry standards and regulations

- Maintaining accurate records of all inspections performed

- Working closely with maintenance personnel to coordinate repairs and replacements

2. Describe the different types of aircraft landing gears and their components.

Types of aircraft landing gears

- Fixed landing gear

- Retractable landing gear

- Skid landing gear

- Float landing gear

- Amphibious landing gear

Components of aircraft landing gear

- Shock absorbers

- Struts

- Axles

- Wheels

- Tires

- Brakes

3. What are the different inspection methods used for aircraft landing gears?

The different inspection methods used for aircraft landing gears include:

- Visual inspection

- Non-destructive testing (NDT)

- Magnetic particle inspection

- Eddy current inspection

- Ultrasonic inspection

- Radiographic inspection

4. What are the most common defects and damages found on aircraft landing gears?

The most common defects and damages found on aircraft landing gears include:

- Cracks

- Corrosion

- Wear

- Impact damage

- Structural deformation

5. What are the critical dimensions and tolerances that must be checked during aircraft landing gear inspection?

The critical dimensions and tolerances that must be checked during aircraft landing gear inspection include:

- Wheel alignment

- Tire wear

- Brake pad thickness

- Strut extension and retraction

- Axle alignment

6. What are the safety precautions that must be taken when inspecting aircraft landing gears?

The safety precautions that must be taken when inspecting aircraft landing gears include:

- Wearing appropriate personal protective equipment (PPE)

- Using the correct tools and equipment

- Following established procedures

- Working in a safe and controlled environment

- Being aware of potential hazards

7. What are the quality standards that must be met during aircraft landing gear inspection?

The quality standards that must be met during aircraft landing gear inspection include:

- AS9100

- ATA Spec 2000

- FAR Part 43

- FAA Advisory Circulars

- Manufacturer’s specifications

8. What are the latest technologies and trends in aircraft landing gear inspection?

The latest technologies and trends in aircraft landing gear inspection include:

- Automated inspection systems

- Robotic inspection

- Non-destructive testing (NDT) advancements

- Predictive maintenance

- Data analytics

9. How do you stay up-to-date with the latest developments in aircraft landing gear inspection?

I stay up-to-date with the latest developments in aircraft landing gear inspection by:

- Attending industry conferences and seminars

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Networking with other aircraft landing gear inspectors

- Taking continuing education courses

10. What are your strengths and weaknesses as an Aircraft Landing Gear Inspector?

My strengths as an Aircraft Landing Gear Inspector include:

- Attention to detail

- Strong technical skills

- Experience with various inspection methods

- Knowledge of industry standards and regulations

- Ability to work independently and as part of a team

My weaknesses as an Aircraft Landing Gear Inspector include:

- Lack of experience with some of the latest technologies

- Limited knowledge of some foreign aircraft models

- Occasionally get distracted by noise or other distractions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Landing Gear Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Landing Gear Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Landing Gear Inspectors play a critical role in ensuring the safety and reliability of aircraft by thoroughly inspecting landing gear systems and components.

1. Inspection and Evaluation

Conduct detailed visual, non-destructive, and destructive inspections of landing gear components, including wheels, tires, brakes, struts, and actuators.

- Analyze inspection data and make informed decisions regarding the serviceability of landing gear systems.

- Identify and document defects, wear, and damage using established inspection techniques and procedures.

2. Maintenance and Repair

Perform scheduled and unscheduled maintenance tasks on landing gear systems, ensuring compliance with safety regulations and manufacturer’s specifications.

- Overhaul and replace landing gear components, including brakes, tires, and actuators.

- Repair or replace damaged or worn landing gear parts to restore full functionality.

3. Documentation and Reporting

Maintain accurate and detailed records of all inspection, maintenance, and repair activities performed on landing gear systems.

- Prepare and submit inspection reports, maintenance logs, and other documentation as required by regulatory authorities.

- Communicate inspection findings and recommendations to maintenance personnel and other stakeholders.

4. Quality Assurance

Implement and maintain quality assurance programs to ensure the highest standards of inspection and maintenance are adhered to.

- Monitor and evaluate inspection and maintenance processes to identify areas for improvement.

- Provide training and guidance to other inspectors and maintenance personnel.

Interview Tips

To ace the interview for an Aircraft Landing Gear Inspector position, it’s essential to prepare thoroughly and demonstrate your knowledge, skills, and passion for aviation safety. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, research the company’s history, values, and current projects. This will show the interviewer that you’re interested in their organization and have taken the time to learn about the role.

- Visit the company’s website and review their mission statement, services, and recent news.

- Check online reviews and industry news to gather insights into the company’s culture and reputation.

2. Highlight Relevant Skills and Experience

In your resume and interview, focus on highlighting your skills and experience that are directly relevant to the job requirements. Use specific examples to demonstrate your abilities.

- Emphasize your experience in landing gear inspection, maintenance, and repair.

- Quantify your accomplishments and use measurable results to support your claims.

3. Prepare for Technical Questions

Expect to answer technical questions about landing gear systems, inspection procedures, and maintenance best practices. Study the relevant materials and be prepared to discuss your knowledge in detail.

- Review industry standards and regulations governing aircraft landing gear inspection.

- Practice answering questions about common landing gear defects and repair techniques.

4. Showcase Your Quality Mindset

Aircraft Landing Gear Inspectors play a crucial role in ensuring the safety of aircraft. In the interview, emphasize your commitment to quality assurance and attention to detail.

- Discuss your experience in implementing and maintaining quality management systems.

- Provide examples of how you have ensured high standards of workmanship and compliance.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your engagement and interest in the role. This shows the interviewer that you’re actively seeking information and considering the opportunity seriously.

- Ask about the company’s safety culture and regulatory compliance practices.

- Inquire about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Landing Gear Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.