Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft Machinist Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

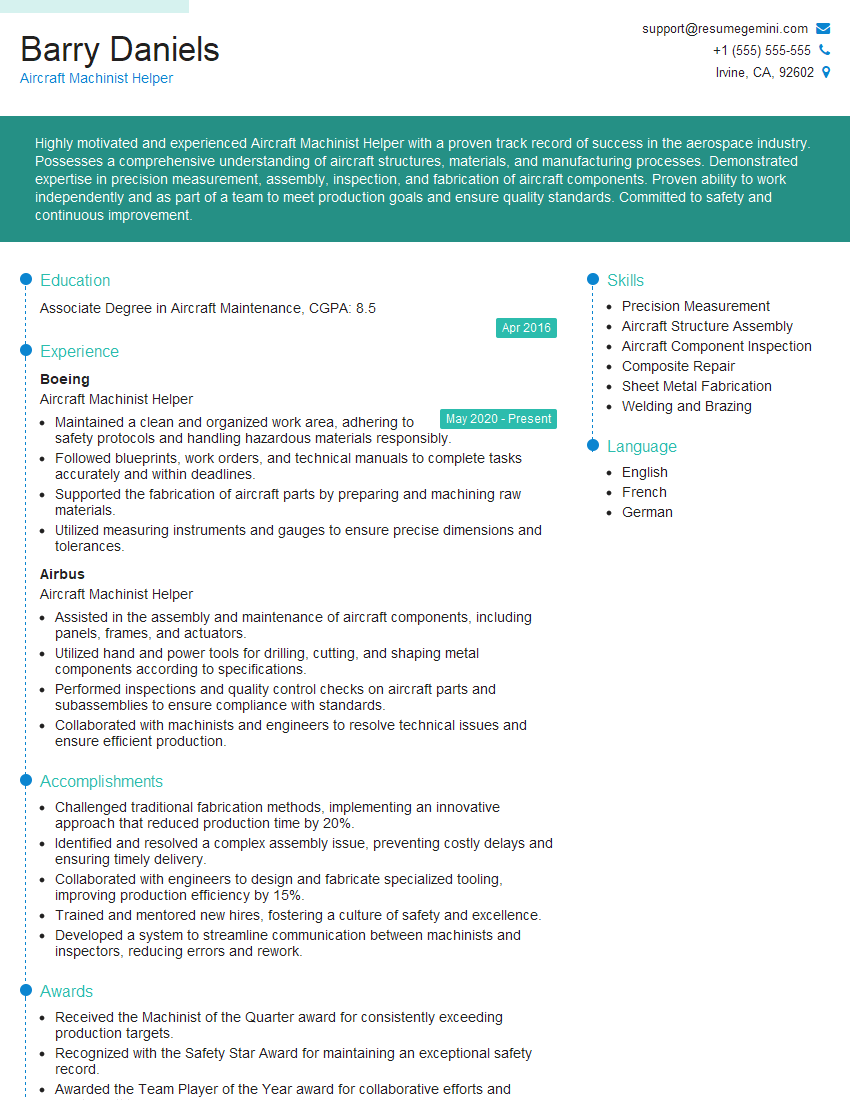

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Machinist Helper

1. What are the different types of aircraft materials and their properties?

There are various types of aircraft materials, each with unique properties to meet specific requirements:

- Aluminum Alloys: High strength-to-weight ratio, corrosion resistance, and weldability. Used for aircraft skins, frames, and wings.

- Composite Materials: Lightweight, high strength, and corrosion-resistant. Used for aircraft structures, wings, and fairings.

- Titanium Alloys: Lightweight, high strength, and heat resistance. Used for aircraft engine components, landing gear, and structural parts.

- Steel Alloys: High strength, wear resistance, and magnetic properties. Used for engine components, landing gear, and high-stress parts.

- Superalloys: High strength, heat resistance, and corrosion resistance. Used for turbine blades, engine components, and high-temperature applications.

2. Describe the different types of aircraft manufacturing processes.

Sheet Metal Fabrication

- Cutting and forming sheet metal into aircraft components using techniques like shearing, punching, and bending.

- Joining techniques include riveting, welding, and bonding.

Machining

- Using machine tools like lathes, mills, and drills to shape and finish aircraft parts from solid materials.

- Requires precise measurements and knowledge of machining techniques.

Composite Fabrication

- Layering and bonding composite materials to create strong, lightweight structures.

- Involves techniques like vacuum bagging, autoclave curing, and resin infusion.

3. What are the quality control procedures involved in aircraft manufacturing?

- Material Inspection: Verifying materials meet specifications before use.

- Process Monitoring: Ensuring manufacturing processes adhere to established standards.

- Dimensional Inspection: Measuring parts to ensure they meet design specifications.

- Non-Destructive Testing: Using techniques like radiography, ultrasound, and magnetic particle inspection to detect defects.

- Final Inspection: Thorough examination of the completed aircraft to ensure compliance with safety and performance requirements.

4. What safety precautions are necessary when working in an aircraft manufacturing facility?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Following machine safety protocols and lockout/tagout procedures.

- Handling hazardous materials with proper training and precautions.

- Maintaining a clean and organized work area to prevent accidents.

- Being aware of potential hazards and reporting any unsafe conditions.

5. What are the major components of an aircraft and their functions?

- Fuselage: Main body of the aircraft, housing the passengers, cargo, and cockpit.

- Wings: Generate lift and control the aircraft’s roll.

- Tail: Provides stability and control during takeoff, landing, and flight.

- Engine: Provides thrust to propel the aircraft.

- Landing Gear: Supports the aircraft on the ground and enables takeoff and landing.

6. What are the key performance indicators (KPIs) used to measure the efficiency of an aircraft manufacturing facility?

- Production Rate: Number of aircraft produced per unit time.

- Lead Time: Time taken from order to delivery.

- Quality: Number of defects or non-conformities per aircraft.

- Cost: Total cost of manufacturing an aircraft.

- Customer Satisfaction: Level of customer satisfaction with the aircraft and manufacturing process.

7. What are the emerging technologies being used in aircraft manufacturing?

- Additive Manufacturing: 3D printing of aircraft components, reducing lead times and material waste.

- Virtual Reality (VR): Used for design, simulation, and training.

- Cloud Computing: Centralized storage and access to design and production data.

- Artificial Intelligence (AI): Used for predictive maintenance, quality control, and optimization.

- Industrial Robotics: Automation of repetitive and hazardous tasks.

8. Describe the role of an Aircraft Machinist Helper in the manufacturing process.

- Assists machinists in operating machine tools, such as lathes, mills, and drills.

- Sets up and prepares workpieces for machining.

- Inspects finished parts for accuracy and quality.

- Maintains and cleans machinery and equipment.

- Follows safety protocols and wears appropriate PPE.

9. What are the necessary qualifications and skills for an Aircraft Machinist Helper?

- Education: High school diploma or equivalent, with courses in mathematics, science, and shop.

- Technical Skills: Knowledge of basic machining principles, tools, and equipment.

- Mechanical Aptitude: Ability to understand mechanical systems and work with precision.

- Attention to Detail: Meticulous in following instructions and ensuring accuracy.

- Teamwork: Ability to work effectively in a team environment.

10. What are your motivations for pursuing a career as an Aircraft Machinist Helper?

- Interest in Aviation: Passion for the aviation industry and a desire to contribute to aircraft manufacturing.

- Career Growth: Opportunity to learn and advance in the field of aircraft machining.

- Job Security: Stable and in-demand industry with a growing need for skilled machinists.

- Pride of Craftsmanship: Satisfaction in producing high-quality aircraft components.

- Contribution to Society: Understanding the importance of aircraft safety and the role of machinists in ensuring it.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Machinist Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Machinist Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Machinist Helper is a highly skilled position responsible for assisting Aircraft Machinists in the fabrication, assembly, and repair of aircraft components and assemblies.

1. Assist with Fabrication and Assembly

Assist Aircraft Machinists in the fabrication and assembly of aircraft components and assemblies, using a variety of tools and equipment.

- Set up and operate machine tools, such as lathes, mills, and drill presses.

- Inspect and measure parts to ensure they meet specifications.

- Assemble and fit parts together, using hand tools and power tools.

2. Assist with Repair and Maintenance

Assist Aircraft Machinists in the repair and maintenance of aircraft components and assemblies.

- Identify and diagnose problems with aircraft components and assemblies.

- Remove and replace damaged parts.

- Reassemble and test repaired components and assemblies.

3. Perform General Maintenance and Housekeeping

Perform general maintenance and housekeeping tasks in the shop.

- Clean and maintain tools and equipment.

- Keep the shop organized and tidy.

- Dispose of waste materials properly.

4. Other Duties

Perform other duties as assigned by the Aircraft Machinist.

- Obtain and transport materials and supplies.

- Assist with the training of new employees.

- Follow all safety regulations and procedures.

Interview Tips

Preparing for an interview for an Aircraft Machinist Helper position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in an Aircraft Machinist Helper.

- Visit the company’s website and social media pages.

- Read news articles and press releases about the company.

- Talk to people who work or have worked for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, so it is important to practice your answers in advance. Some of the most common questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with aircraft fabrication and assembly?

- What is your safety record?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire.

- Be clean and well-groomed.

- Arrive at the interview location at least 10 minutes early.

4. Be Yourself and Be Enthusiastic

It is important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you and see if you are a good fit for the position. Be honest about your experience and skills, and be sure to highlight your passion for aircraft fabrication and assembly.

- Be confident and articulate.

- Make eye contact with the interviewer.

- Smile and show your enthusiasm for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Machinist Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!