Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft Metalsmith position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

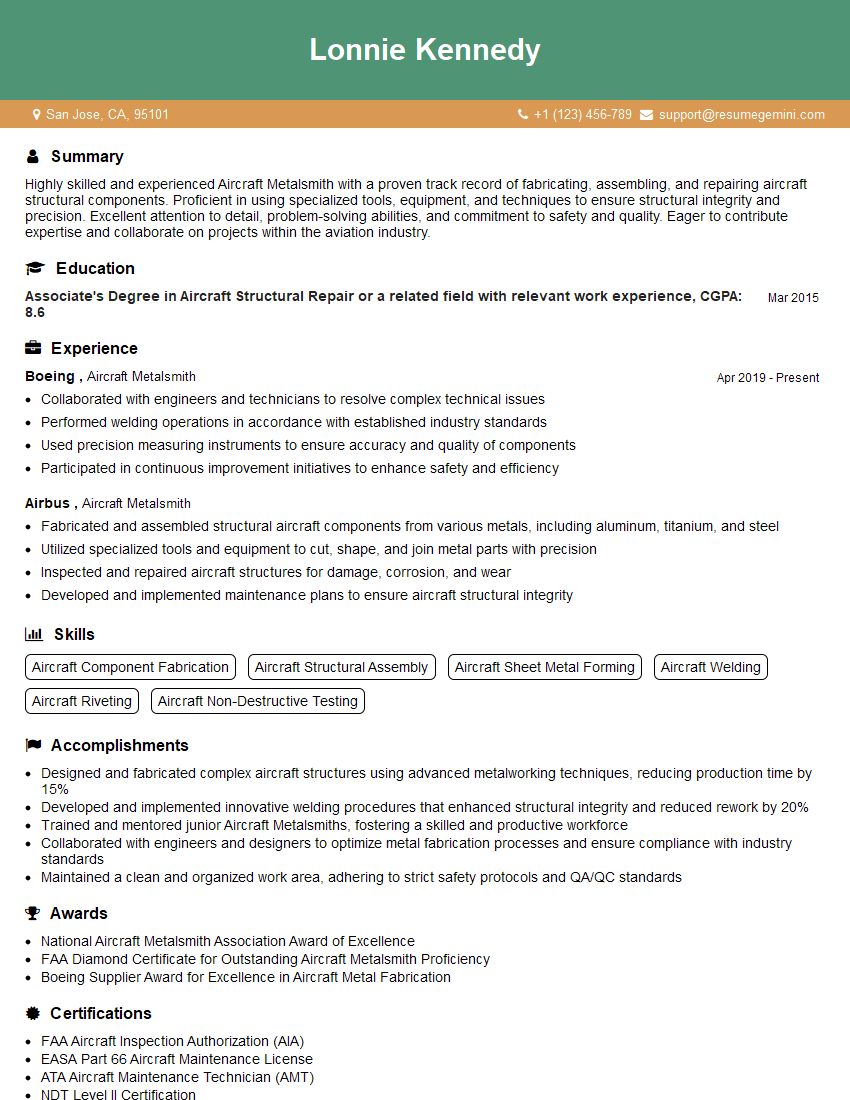

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Metalsmith

1. What are the different types of aircraft metalsmithing techniques?

Here are some of the different types of aircraft metalsmithing techniques:

- Forming: Shaping metal using various tools and machines, such as presses, hammers, and rolls.

- Welding: Joining metal pieces together using heat and filler material.

- Riveting: Joining metal pieces together using rivets.

- Brazing: Joining metal pieces together using a lower-melting-point metal alloy.

- Soldering: Joining metal pieces together using a lower-melting-point metal alloy, typically with a flux.

2. What are the different materials used in aircraft metalsmithing?

Ferrous Metals

- Steel: A strong and durable material used for a variety of aircraft components, including structural members, landing gear, and engine parts.

- Stainless steel: A corrosion-resistant steel alloy used for applications where resistance to rust and other forms of corrosion is important.

Non-Ferrous Metals

- Aluminum: A lightweight and strong metal used for a variety of aircraft components, including skins, wings, and fuselages.

- Titanium: A strong and lightweight metal used for high-performance aircraft components, such as engine parts and landing gear.

- Composite materials: A combination of materials, such as fiberglass, carbon fiber, and epoxy resin, used for lightweight and durable aircraft structures.

3. What are the safety precautions that must be taken when working as an aircraft metalsmith?

Here are some of the safety precautions that must be taken when working as an aircraft metalsmith:

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator.

- Be aware of the hazards of working with sharp tools and machinery.

- Follow all safety procedures and guidelines.

- Inspect tools and equipment regularly to ensure they are in good working condition.

- Never work alone, always have a partner or supervisor present.

4. What are the different types of aircraft structures?

Here are some of the different types of aircraft structures:

- Fuselage: The main body of the aircraft that houses the passengers, cargo, and crew.

- Wings: The airfoils that generate lift and allow the aircraft to fly.

- Tail: The rear section of the aircraft that provides stability and control.

- Landing gear: The system that supports the aircraft on the ground and allows it to take off and land.

- Propulsion system: The system that provides thrust to propel the aircraft forward.

5. What are the different types of aircraft maintenance?

Here are some of the different types of aircraft maintenance:

- Preventive maintenance: Regular inspections and servicing to prevent failures and keep the aircraft in good working condition.

- Corrective maintenance: Repairs and replacements to fix problems and return the aircraft to service.

- Overhaul: A major maintenance event that involves a complete inspection and refurbishment of the aircraft.

- Modification: Changes to the aircraft to improve its performance or capabilities.

6. What are the different types of aircraft inspections?

Here are some of the different types of aircraft inspections:

- Pre-flight inspection: A quick inspection performed before each flight to ensure the aircraft is safe to fly.

- Daily inspection: A more thorough inspection performed each day to check for any problems that may have developed since the last flight.

- Weekly inspection: A more comprehensive inspection performed each week to check for any signs of wear or damage.

- Monthly inspection: A major inspection performed each month to check for any major problems that may require repair.

- Annual inspection: A comprehensive inspection performed each year to ensure the aircraft is in good working condition and meets all safety regulations.

7. What are the different types of aircraft repairs?

Here are some of the different types of aircraft repairs:

- Minor repairs: Small repairs that can be made quickly and easily, such as fixing a leak or replacing a light bulb.

- Major repairs: Larger repairs that require more time and effort, such as repairing a damaged wing or replacing an engine.

- Structural repairs: Repairs to the aircraft’s structure, such as repairing a cracked fuselage or replacing a damaged wing.

- Avionics repairs: Repairs to the aircraft’s electronic systems, such as repairing a navigation system or replacing a radar.

8. What are the different types of aircraft modifications?

Here are some of the different types of aircraft modifications:

- Performance modifications: Modifications to improve the aircraft’s performance, such as adding winglets or installing a more powerful engine.

- Avionics modifications: Modifications to the aircraft’s electronic systems, such as installing a new navigation system or adding a weather radar.

- Interior modifications: Modifications to the aircraft’s interior, such as adding new seats or installing a custom entertainment system.

- Exterior modifications: Modifications to the aircraft’s exterior, such as adding a new paint scheme or installing a new wing.

9. Describe your experience with using aircraft maintenance manuals.

In my previous role, I was responsible for using aircraft maintenance manuals on a daily basis to perform a variety of tasks, including:

- Troubleshooting aircraft problems

- Performing scheduled maintenance checks

- Repairing aircraft components

- Modifying aircraft systems

10. What is your experience with working with composite materials?

I have experience working with composite materials in a variety of settings, including:

- Manufacturing composite parts for aircraft

- Repairing composite structures

- Inspecting composite components

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Metalsmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Metalsmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Metalsmiths are skilled craftsmen responsible for fabricating, assembling, and repairing aircraft structures and components using specialized metalworking techniques. Their key job responsibilities include:

1. Fabrication

Interpret technical drawings to create and fabricate new aircraft parts and components according to specifications.

2. Assembly

Assemble aircraft structures and components using rivets, bolts, and other fasteners to ensure proper fit and alignment.

3. Repair

Inspect and repair damaged aircraft structures and components using welding, riveting, and other techniques to restore their functionality.

4. Inspection

Perform quality inspections on finished products to ensure compliance with design specifications and safety standards.

5. Maintenance

Maintain and calibrate specialized equipment used in the fabrication and repair process, such as welding machines and sheet metal shears.

Interview Tips

Preparing thoroughly for an Aircraft Metalsmith interview is crucial for showcasing your skills and increasing your chances of success. Here are some essential tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and the specific role you’re applying for. Demonstrate your knowledge of the aviation industry and current trends.

2. Highlight Relevant Experience

Emphasize your experience in metalworking, fabrication, and repair techniques. Quantify your accomplishments with specific examples and metrics whenever possible.

3. Prepare for Technical Questions

Review common interview questions related to Aircraft Metalsmithing, such as how to inspect aircraft components for defects or how to fabricate a specific part. Be prepared to discuss your knowledge of different materials and techniques.

4. Show Your Safety Consciousness

Aircraft Metalsmiths must adhere to strict safety regulations. Highlight your commitment to following safety protocols and your understanding of hazardous materials and equipment.

5. Demonstrate Teamwork and Communication

Collaboration is essential in this field. Emphasize your ability to work effectively in a team environment and communicate clearly with colleagues and supervisors.

6. Practice Common Interview Questions

Familiarize yourself with common interview questions, such as “Why are you interested in this role?” or “What are your strengths and weaknesses?”. Practice your responses to ensure they are concise, relevant, and highlight your qualifications.

7. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview demonstrates your interest and engagement. Prepare a few questions about the company’s culture, growth opportunities, or specific projects related to the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Aircraft Metalsmith, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Aircraft Metalsmith positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.