Are you gearing up for a career in Aircraft Motor Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Aircraft Motor Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

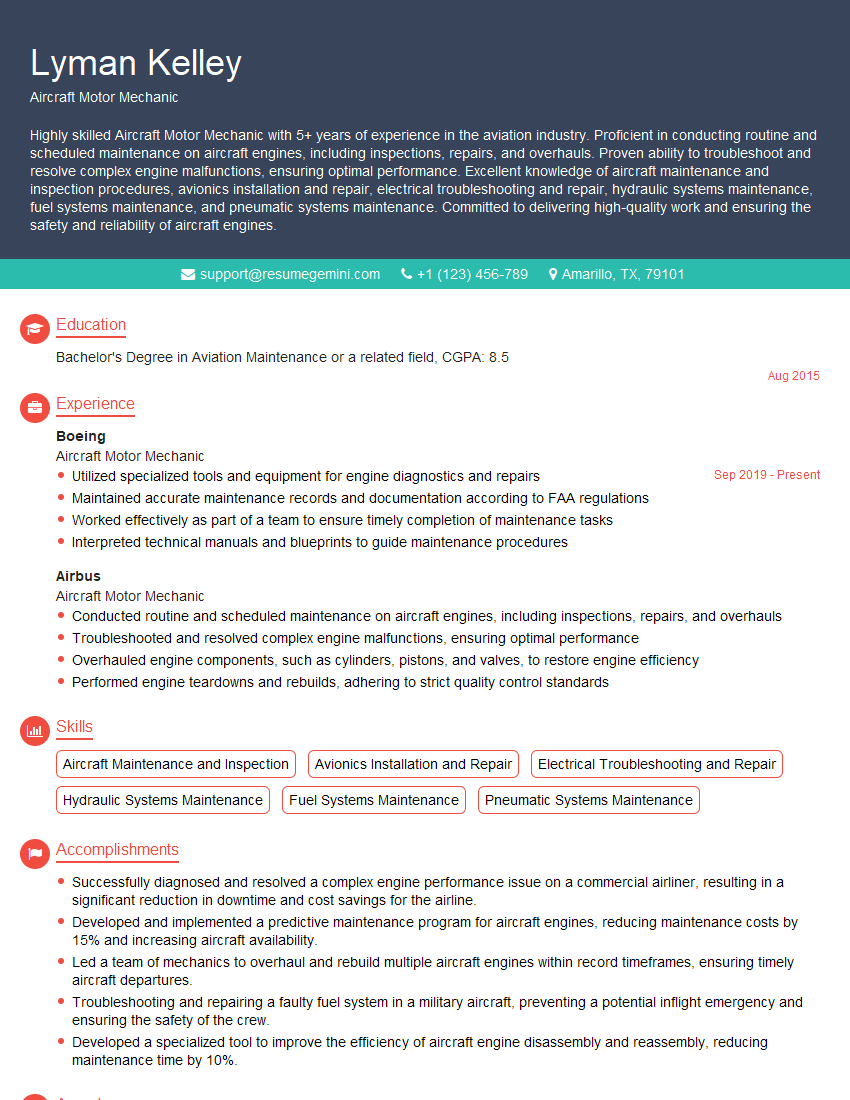

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Motor Mechanic

1. What are the different types of aircraft engines, and how do they work?

- Reciprocating engines: These engines use pistons to convert the reciprocating motion of the pistons into rotary motion. They are typically used in small aircraft.

- Turboprop engines: These engines use a gas turbine to drive a propeller. They are more efficient than reciprocating engines and are used in a wide range of aircraft, from small planes to large airliners.

- Turbojet engines: These engines use a gas turbine to generate thrust. They are very efficient and are used in high-speed aircraft, such as military jets and commercial airliners.

- Turbofan engines: These engines are a hybrid of turbojet and turboprop engines. They use a gas turbine to drive a fan, which generates thrust. They are very efficient and are used in a wide range of aircraft, from small planes to large airliners.

2. What are the different types of aircraft engine inspections, and how often are they required?

subheading of the answer

- Pre-flight inspections: These inspections are performed before every flight to ensure that the engine is operating properly. They typically include a visual inspection of the engine, as well as a check of the engine’s oil level and pressure.

- Periodic inspections: These inspections are performed at regular intervals, such as every 50 or 100 hours of operation. They include a more thorough inspection of the engine, as well as a check of the engine’s spark plugs and filters.

- Major inspections: These inspections are performed less frequently, such as every 1,000 or 2,000 hours of operation. They include a complete disassembly of the engine, as well as a check of all of the engine’s components.

subheading of the answer

- The frequency of aircraft engine inspections varies depending on the type of engine and the aircraft it is installed in. However, all aircraft engines must be inspected in accordance with the manufacturer’s recommendations.

3. What are the different types of aircraft engine maintenance tasks, and how are they performed?

- Routine maintenance: These tasks are performed on a regular basis to keep the engine operating properly. They include tasks such as changing the engine’s oil and filter, and inspecting the engine’s spark plugs and filters.

- Scheduled maintenance: These tasks are performed at regular intervals, such as every 50 or 100 hours of operation. They include more thorough inspections of the engine, as well as tasks such as cleaning the engine’s fuel injectors and replacing the engine’s spark plugs.

- Unscheduled maintenance: These tasks are performed as needed to repair or replace damaged or worn engine components. They can range from simple tasks, such as replacing a spark plug, to more complex tasks, such as overhauling the engine.

4. What are the different types of aircraft engine troubleshooting techniques, and how are they used?

- Visual inspection: This technique involves looking for any obvious signs of damage or wear on the engine. It can be used to identify problems such as leaks, cracks, and loose connections.

- Audible inspection: This technique involves listening for any unusual noises coming from the engine. It can be used to identify problems such as knocking, squealing, and grinding.

- Diagnostic testing: This technique involves using specialized equipment to test the engine’s performance. It can be used to identify problems such as fuel flow problems, ignition problems, and compression problems.

5. What are the different types of aircraft engine repair techniques, and how are they used?

- Component replacement: This technique involves replacing damaged or worn engine components with new or refurbished components. It is the most common type of engine repair technique.

- Component repair: This technique involves repairing damaged or worn engine components instead of replacing them. It is less common than component replacement, but it can be more cost-effective.

- Engine overhaul: This technique involves completely disassembling the engine and rebuilding it using new or refurbished components. It is the most expensive type of engine repair technique, but it can also restore the engine to its original condition.

6. What are the different types of aircraft engine modifications, and how are they approved?

- Minor modifications: These modifications do not affect the aircraft’s airworthiness or performance. They can be approved by the aircraft manufacturer or by a designated representative.

- Major modifications: These modifications affect the aircraft’s airworthiness or performance. They must be approved by the aircraft’s certification authority.

7. What are the different types of aircraft engine safety regulations, and how are they enforced?

- The Federal Aviation Administration (FAA) has a number of regulations in place to ensure the safety of aircraft engines. These regulations cover everything from the design and manufacture of engines to their maintenance and operation.

- The FAA enforces its regulations through a variety of means, including inspections, audits, and enforcement actions.

8. What are the different types of aircraft engine certification requirements, and how are they met?

- The FAA has a number of certification requirements in place to ensure that aircraft engines are safe and reliable. These requirements cover everything from the design and manufacture of engines to their maintenance and operation.

- To meet the FAA’s certification requirements, engine manufacturers must submit their engines for testing and evaluation. The FAA will then issue a certificate of airworthiness if the engine meets all of the applicable requirements.

9. What is the role of an aircraft engine mechanic, and what are the key responsibilities of the role?

- An aircraft engine mechanic is responsible for the maintenance, repair, and overhaul of aircraft engines.

- Key responsibilities of the role include:

- Inspecting engines for damage or wear

- Troubleshooting engine problems

- Repairing or replacing engine components

- Overhauling engines

- Ensuring that engines are safe and reliable

10. What are the different career paths available to aircraft engine mechanics, and how can you progress in the field?

- Aircraft engine mechanics can progress in their careers by gaining experience and additional training. They can also move into management positions or become specialized in a particular area of engine maintenance, such as troubleshooting or overhaul.

- Some common career paths for aircraft engine mechanics include:

- Lead aircraft engine mechanic

- Supervisor

- Manager

- Quality control inspector

- Technical writer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Motor Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Motor Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft motor mechanics, ensure that every type of aircraft, from the smallest trainer to the largest, most complicated jet, remains in the air. They have a broad range of mechanical experience and expertise with aircraft engine testing, dismantling, and reassembly. They must keep a wide range of technical documents up to date and understand parts catalogs, technical orders, and maintenance manuals. Aircraft motor mechanics have a comprehensive knowledge of electrical and mechanical systems.

1. Inspection and troubleshooting

troubleshooting and repair of aircraft engines, components, and systems

- Inspects and repairs engines, propellers, and related components

- Diagnoses and repairs electrical, hydraulic, and pneumatic systems

2. Engine Maintenance and Repairs

Inspecting, evaluating, and repairing aircraft engines and related components

- Overhauls and repairs engines, including disassembly, cleaning, and reassembly

- Replaces worn or damaged parts

3. Documentation

Maintaining accurate records of repairs and inspections, as well as completing and submitting reports

- Maintains records of all inspections, repairs, and maintenance performed

- Prepares and submits reports on the condition of aircraft engines and components

4. Safety Compliance

Ensuring that all maintenance and repairs are performed in accordance with established safety standards and regulations, while adhering to quality control procedures

- Follows all safety regulations and procedures

- Ensures that all repairs are performed to the highest standards of quality

5. Communication and Teamwork

Communicating effectively with other mechanics, engineers, and pilots to ensure that aircraft are safe and airworthy

- Works as part of a team to maintain and repair aircraft

- Communicates with pilots and other personnel to ensure that aircraft are safe and airworthy

Interview Tips

Preparing for an aircraft motor mechanic interview can be a daunting task, but following a few simple tips can help you put your best foot forward and increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interviewing for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Research common interview questions specific to Aircraft Motor Mechanics.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the job you’re applying for. Use specific examples to demonstrate your abilities and how you’ve used them in the past. When describing your skills, use specific examples to demonstrate how you have applied them in previous roles. Quantify your accomplishments whenever possible, using numbers and metrics.

- Prepare examples of your work that demonstrate your skills and experience.

4. Be Prepared to Talk About Your Safety Knowledge

Aircraft motor mechanics must have a deep understanding of safety regulations and procedures. In your interview, be prepared to talk about your safety knowledge and how you ensure that your work meets all applicable standards.

- Be familiar with the FAA regulations and industry best practices for aircraft maintenance.

5. Be Enthusiastic and Professional

First impressions matter, so it’s important to be enthusiastic and professional in your interview. Dress appropriately, arrive on time, and be polite and respectful to everyone you meet. Throughout the interview, maintain a positive attitude and demonstrate your passion for aviation. By following these tips, you can increase your chances of success in your aircraft motor mechanic interview.

- Dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you meet, including the receptionist, other employees, and the interviewer.

- Maintain a positive attitude throughout the interview and demonstrate your passion for aviation.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Aircraft Motor Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Aircraft Motor Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.