Feeling lost in a sea of interview questions? Landed that dream interview for Aircraft Pneudraulics Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aircraft Pneudraulics Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

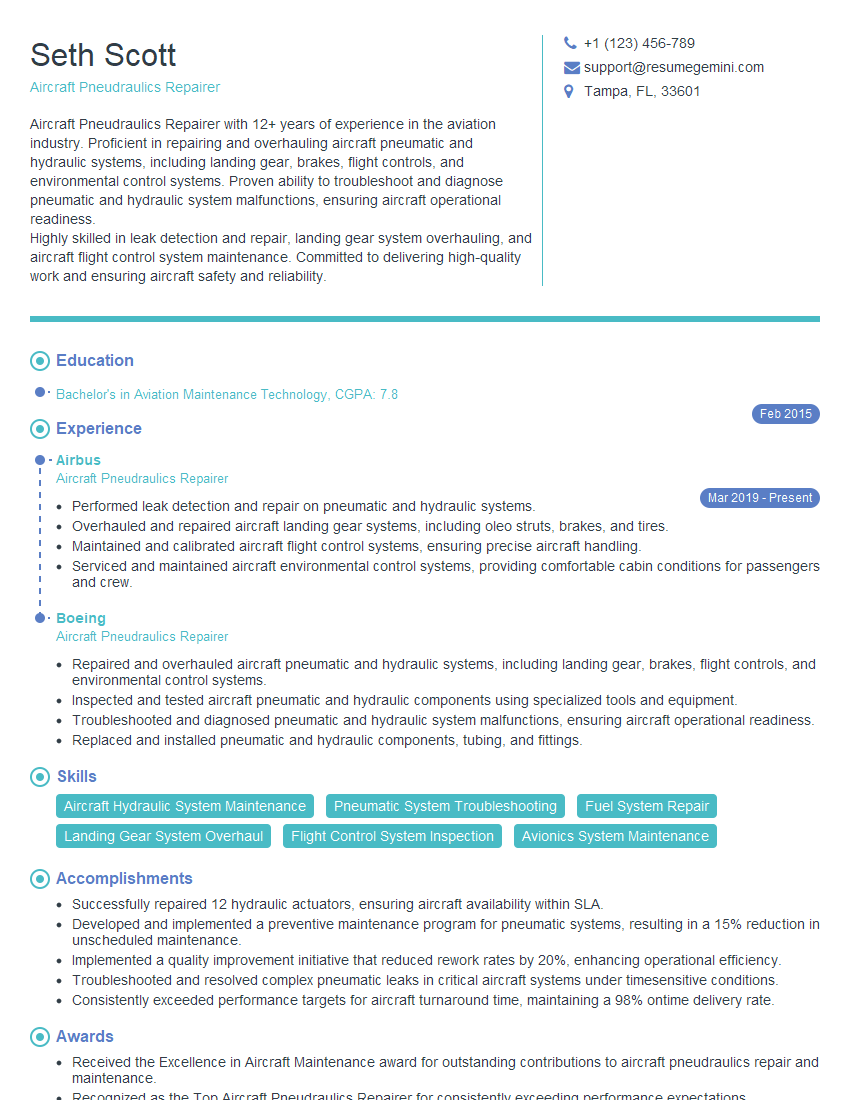

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Pneudraulics Repairer

1. Explain the working principle of a hydraulic system used in aircraft?

A hydraulic system in an aircraft utilizes the principles of fluid dynamics to transmit power and control movement. Here’s a brief overview of its working principle:

- Reservoir: Stores the hydraulic fluid and acts as a source for the system.

- Pump: Converts mechanical energy into hydraulic energy by drawing fluid from the reservoir and pressurizing it.

- Control Valve: Regulates the flow of pressurized fluid to various components.

- Actuator: Utilizes the pressurized fluid to perform mechanical work, such as moving flight control surfaces.

- Return Line: Carries the used fluid back to the reservoir, completing the circuit.

2. Describe the different types of hydraulic fluids used in aircraft and their properties?

Mineral-Based Hydraulic Fluids

- Petroleum-based fluids, commonly used in older aircraft.

- Highly flammable and require careful handling.

Synthetic Hydraulic Fluids

- Fire-resistant and non-flammable fluids.

- Higher thermal stability and longer service life.

Biodegradable Hydraulic Fluids

- Environmentally friendly and non-toxic fluids.

- Lower performance and higher cost compared to synthetic fluids.

3. What are the key maintenance procedures for aircraft pneumatic systems?

Maintaining pneumatic systems in aircraft involves regular inspections, checks, and servicing to ensure optimal performance and safety. Key maintenance procedures include:

- Leak checks: Inspecting hoses, fittings, and components for any leaks or damage.

- Pressure checks: Verifying the system’s operating pressure and identifying any deviations.

- Filter inspections: Replacing or cleaning filters to ensure clean air supply and prevent contamination.

- Valve inspections: Checking valves for proper operation, leaks, and corrosion.

- Compressor servicing: Inspecting, cleaning, and servicing the compressor unit for optimal performance.

4. Explain the troubleshooting process for a hydraulic system that is not providing sufficient pressure?

When a hydraulic system is not providing sufficient pressure, it’s crucial to follow a systematic troubleshooting process to identify and resolve the issue. Here’s a general approach:

- Check fluid level: Verify that the hydraulic fluid reservoir has an adequate amount of fluid.

- Inspect for leaks: Examine the entire system for any visible leaks or damage.

- Test pump: Use a pressure gauge to measure the pump’s output pressure and compare it to the system specifications.

- Inspect control valve: Check the control valve for proper operation and ensure it is receiving the correct electrical signals or mechanical inputs.

- Examine actuators: Verify that the hydraulic actuators are functioning correctly and not binding or leaking.

5. How do you ensure the proper operation of an aircraft brake system?

Maintaining the proper operation of an aircraft brake system is critical for safe and efficient landings. Here are some key steps:

- Regular inspections: Regularly inspect brake components, including pads, rotors, and calipers, for wear and damage.

- Brake fluid checks: Monitor brake fluid levels and condition, ensuring there are no leaks or contamination.

- Pressure tests: Conduct pressure tests to verify the system’s ability to generate and maintain sufficient brake pressure.

- Servicing and lubrication: Service and lubricate brake components as per the manufacturer’s recommendations.

- Functional checks: Perform functional checks to ensure proper brake operation, including taxi tests and flight checks.

6. Describe the different types of aircraft landing gear and their maintenance requirements?

Fixed Landing Gear

- Permanently attached to the aircraft, providing stability on the ground.

- Requires less maintenance, primarily involving lubrication and inspections.

Retractable Landing Gear

- Can be retracted into the aircraft during flight to reduce drag.

- Requires more maintenance, including regular inspections, lubrication, and actuator servicing.

Taildragger Landing Gear

- Features a single wheel at the tail and two main wheels in front.

- Requires specific maintenance procedures, such as tailwheel shimmy checks and brake adjustments.

7. What are the safety protocols and regulations that must be followed when working on aircraft pneumatic and hydraulic systems?

Working on aircraft pneumatic and hydraulic systems requires strict adherence to safety protocols and regulations to ensure the safety of personnel and the aircraft itself.

- Proper training and certification: Technicians must be trained and certified to work on aircraft systems.

- Personal protective equipment: Wear appropriate personal protective equipment, including gloves, eye protection, and hearing protection.

- System isolation: Isolate the system being worked on to prevent accidental activation or fluid leaks.

- Pressure release: Release system pressure before disconnecting or opening components.

- Grounding: Ground the system to prevent static discharge.

8. Explain the importance of proper lubrication in aircraft pneumatic and hydraulic systems?

Proper lubrication is crucial in aircraft pneumatic and hydraulic systems for several reasons:

- Reduces friction: Lubricants reduce friction between moving parts, preventing excessive wear and extending component life.

- Prevents corrosion: Lubricants create a protective layer on metal surfaces, reducing the risk of corrosion and rust.

- Cools components: Lubricants help dissipate heat generated by friction, preventing overheating and damage.

- Improves efficiency: Well-lubricated systems operate more efficiently, reducing energy consumption and improving system performance.

9. What are the common troubleshooting techniques used to diagnose faults in aircraft pneumatic and hydraulic systems?

Various troubleshooting techniques are used to identify and diagnose faults in aircraft pneumatic and hydraulic systems:

- Visual inspections: Examining components for leaks, damage, or loose connections.

- Pressure checks: Measuring system pressure using gauges to detect pressure deviations.

- Flow checks: Checking fluid flow rates to identify blockages or restrictions.

- Electrical tests: Testing electrical components, such as sensors and solenoids, for proper operation.

- Functional tests: Operating the system under simulated conditions to observe its performance and identify any issues.

10. Discuss the role of technology in the maintenance and repair of aircraft pneumatic and hydraulic systems?

Technology plays a significant role in the maintenance and repair of aircraft pneumatic and hydraulic systems:

- Diagnostics tools: Advanced diagnostic tools, such as computer-aided testing equipment, help identify faults more accurately and efficiently.

- Monitoring systems: Monitoring systems provide real-time data on system performance, allowing for proactive maintenance and early fault detection.

- Virtual reality and augmented reality: These technologies enhance training and maintenance procedures, providing interactive and immersive experiences.

- Data analytics: Data analytics tools help analyze maintenance data to identify trends, predict failures, and optimize maintenance schedules.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Pneudraulics Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Pneudraulics Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Pneudraulics Repairers are responsible for the maintenance and repair of aircraft pneumatic and hydraulic systems. These systems are essential for the safe and efficient operation of aircraft, and Aircraft Pneudraulics Repairers play a critical role in ensuring that these systems are functioning properly. Some of the key job responsibilities of Aircraft Pneudraulics Repairers include:1. Inspecting and testing pneumatic and hydraulic systems.

Aircraft Pneudraulics Repairers are responsible for inspecting and testing pneumatic and hydraulic systems to identify any potential problems. They use a variety of tools and equipment to test the pressure, flow, and temperature of these systems.2. Troubleshooting and repairing pneumatic and hydraulic systems.

When Aircraft Pneudraulics Repairers identify a problem with a pneumatic or hydraulic system, they are responsible for troubleshooting and repairing the problem. They use their knowledge of these systems to diagnose the problem and make the necessary repairs.3. Replacing and installing pneumatic and hydraulic components.

Aircraft Pneudraulics Repairers are also responsible for replacing and installing pneumatic and hydraulic components. They work with a variety of tools and equipment to remove and install these components.4. Maintaining records of maintenance and repairs.

Aircraft Pneudraulics Repairers are responsible for maintaining records of all maintenance and repairs that they perform. These records are used to track the history of the aircraft and to ensure that the systems are functioning properly.Interview Tips

Interviewing for a job as an Aircraft Pneudraulics Repairer can be a challenging process. However, there are a few things that you can do to prepare for the interview and increase your chances of success.1. Research the company and the position.

Before you go to an interview, it is important to research the company and the position that you are applying for. This will help you to understand the company’s culture and values, and the specific requirements of the position. You can research the company on their website, in industry publications, and by talking to people who work there.2. Practice your answers to common interview questions.

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.3. Be prepared to talk about your experience and skills.

The interviewer will want to know about your experience and skills as an Aircraft Pneudraulics Repairer. Be prepared to talk about your work history, your education, and any certifications that you have. You should also be prepared to demonstrate your skills by describing specific projects that you have worked on.4. Ask questions about the position and the company.

At the end of the interview, you should have the opportunity to ask the interviewer questions about the position and the company. This is a good opportunity to learn more about the company and the position, and to show the interviewer that you are interested in the job.5. Follow up after the interview.

After the interview, it is important to follow up with the interviewer. You can do this by sending a thank-you note or by calling the interviewer to check on the status of your application. Following up shows the interviewer that you are interested in the position and that you are serious about getting the job.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Pneudraulics Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!