Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft Rigging and Controls Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

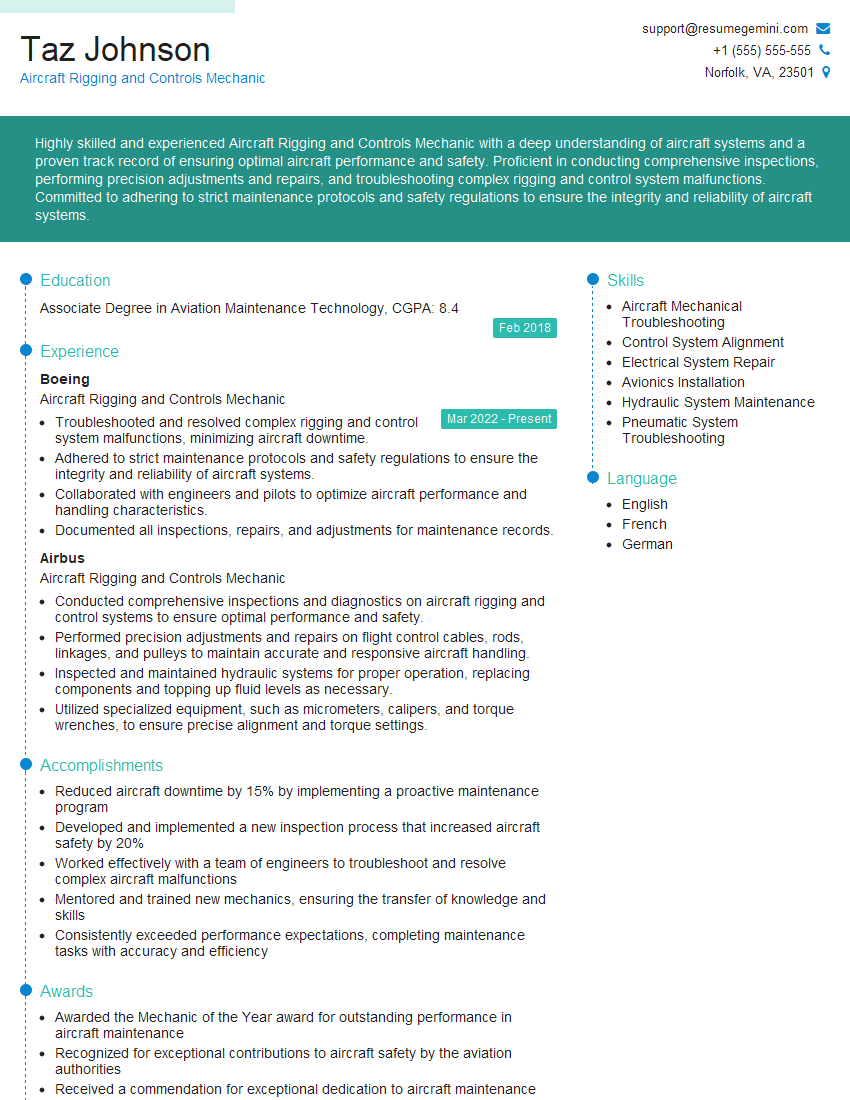

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Rigging and Controls Mechanic

1. How do you ensure proper rigging and control of aircraft systems?

To ensure proper rigging and control of aircraft systems, I meticulously follow established maintenance manuals and industry best practices. I utilize specialized tools and equipment to inspect, adjust, and calibrate flight control systems, ensuring they meet stringent safety and performance standards. I also conduct thorough operational checks and functional tests to verify the proper functioning of all control surfaces, ensuring optimal aircraft performance and handling.

2. What techniques do you employ to troubleshoot and resolve complex aircraft control system issues?

Diagnostic Tools

- Utilize diagnostic equipment and computer systems to identify faults and malfunctions.

- Analyze data logs, fault codes, and system parameters to pinpoint the root cause of issues.

Problem-Solving Approach

- Systematically isolate the problem by dividing the system into smaller components.

- Inspect and test individual components to determine the source of the malfunction.

- Consult technical manuals, engineering drawings, and consult with experts to develop repair solutions.

3. Explain the importance of maintaining proper tension and alignment in aircraft control systems.

Maintaining proper tension and alignment in aircraft control systems is crucial for the safe and efficient operation of the aircraft. Correct tension ensures precise and responsive control surface movements, enhancing aircraft stability and maneuverability. Proper alignment prevents binding, excessive wear, and premature failure of components, ensuring smooth and reliable operation of the control system. Deviations from optimal tension and alignment can compromise flight safety and lead to costly repairs.

4. How do you ensure compliance with industry regulations and safety standards while performing aircraft rigging and control maintenance tasks?

To ensure compliance with industry regulations and safety standards, I adhere to the following principles:

- Thoroughly review and comprehend maintenance manuals, technical orders, and regulatory documents.

- Utilize approved tools, equipment, and materials specified by the manufacturer and regulatory authorities.

- Follow established procedures and best practices outlined in industry standards and guidelines.

- Document all maintenance activities, including inspections, adjustments, repairs, and modifications, in accordance with regulatory requirements.

- Seek guidance from licensed engineers, inspectors, and other qualified personnel when necessary.

5. Describe your experience in using specialized equipment and tools for aircraft rigging and control maintenance.

Throughout my career, I have gained proficiency in utilizing a wide range of specialized equipment and tools for aircraft rigging and control maintenance. These include:

- Tension measuring devices and torque wrenches to ensure precise adjustment of control systems.

- Laser alignment systems for accurate alignment of flight control surfaces and components.

- Hydraulic test equipment to verify proper operation of hydraulic flight control systems.

- Electrical test equipment to troubleshoot and repair electrical control systems and components.

- Specialized tools designed specifically for aircraft rigging and control maintenance, such as cable cutters, swaging tools, and tensioning devices.

6. Explain the process of inspecting and repairing aircraft control cables and pulleys.

The inspection and repair of aircraft control cables and pulleys involve the following steps:

- Inspection: Visually examine cables for fraying, kinking, corrosion, or damage. Inspect pulleys for wear, cracks, or binding.

- Tension Check: Measure cable tension using a tension meter and adjust as necessary to meet specifications.

- Lubrication: Apply appropriate lubricants to pulleys and cable ends to reduce friction and wear.

- Repair: If damage is detected, replace the affected cable or pulley. Use swaging techniques to secure new cables and ensure proper termination.

- Documentation: Record all inspection and repair activities in accordance with maintenance manuals and regulatory requirements.

7. Discuss the importance of balancing and rigging aircraft flight control surfaces.

Balancing and rigging aircraft flight control surfaces is essential for:

- Control Harmony: Ensures that all control surfaces move in unison, providing balanced and responsive aircraft handling.

- Reduced Fatigue: Proper balancing minimizes control forces, reducing pilot fatigue during extended flights.

- Improved Performance: Optimizes aircraft stability, maneuverability, and overall flight characteristics.

- Safety: Balanced and rigged control surfaces enhance aircraft controllability, contributing to overall flight safety.

8. Describe the procedures for adjusting and calibrating aircraft flight controls.

Adjusting and calibrating aircraft flight controls involves:

- Control Rigging: Adjusting the length and tension of control cables and linkages to ensure proper movement and balance of flight control surfaces.

- Trim Tab Adjustment: Setting trim tabs to minimize control forces and improve aircraft stability during various flight conditions.

- Calibration: Using specialized equipment to verify the accuracy and functionality of flight control systems, such as ailerons, elevators, and rudders.

- Functional Checks: Conducting operational tests to ensure the proper functioning of all flight control systems before aircraft operation.

9. Explain the role of hydraulic systems in aircraft flight control.

Hydraulic systems play a crucial role in aircraft flight control by:

- Power Transmission: Hydraulic systems transmit power from a central source to actuate flight control surfaces, such as ailerons, elevators, and rudders.

- Control Force Reduction: Hydraulic systems amplify pilot input, reducing the physical effort required to operate flight controls.

- Redundancy: Multiple hydraulic systems provide redundancy, ensuring continued flight control in case of a single system failure.

- Power Management: Hydraulic systems manage the distribution and flow of hydraulic fluid to ensure optimal performance of flight control systems.

10. Discuss the importance of following maintenance manuals and industry best practices in aircraft rigging and control maintenance.

Adhering to maintenance manuals and industry best practices is vital in aircraft rigging and control maintenance for the following reasons:

- Safety: Following established procedures ensures that aircraft rigging and control systems meet strict safety standards, minimizing the risk of accidents.

- Reliability: Maintenance manuals provide detailed instructions and specifications, ensuring consistent and reliable maintenance practices.

- Efficiency: Using industry best practices optimizes maintenance processes, reducing downtime and increasing aircraft availability.

- Compliance: Maintenance manuals and industry regulations provide a framework for compliance with regulatory requirements.

- Training: Maintenance manuals serve as a valuable training resource for aircraft mechanics, ensuring they have the necessary knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Rigging and Controls Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Rigging and Controls Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Rigging and Controls Mechanics are responsible for the maintenance and repair of aircraft rigging and control systems, which are critical for the safe and efficient operation of aircraft. Their primary duties include:

1. Inspection

Performing regular inspections of aircraft rigging and control systems to identify any potential defects or damage. This may involve visual, physical, or instrumental inspections, and the use of specialized tools and equipment.

- Inspecting aircraft flight controls, including ailerons, elevators, and rudders, for proper alignment and operation.

- Checking cables, pulleys, and other rigging components for signs of wear, corrosion, or damage.

2. Maintenance

Conducting preventive and corrective maintenance on aircraft rigging and control systems, following established procedures and specifications. This may involve lubrication, adjustment, replacement of components, and troubleshooting of malfunctions.

- Lubricating and adjusting control cables and pulleys to ensure smooth and precise operation.

- Replacing worn or damaged rigging components, such as cables, bearings, and fairleads.

3. Repair

Performing repairs on damaged or malfunctioning aircraft rigging and control systems, as required. This may involve welding, riveting, or other fabrication techniques, as well as the replacement of major components.

- Repairing or replacing damaged flight control surfaces, such as ailerons or elevators.

- Troubleshooting and repairing electrical or hydraulic systems associated with aircraft controls.

4. Documentation

Maintaining accurate and up-to-date records of all inspection, maintenance, and repair work performed on aircraft rigging and control systems. This includes preparing work orders, maintenance logs, and other documentation.

- Documenting the details of inspections, including any defects or damage identified.

- Keeping records of all maintenance and repair work performed, including the parts used and the time spent.

Interview Tips

To ace the interview for an Aircraft Rigging and Controls Mechanic position, it is important to be well-prepared and knowledgeable about the industry and the specific role. Here are some tips to help you prepare:

1. Research the Position

Thoroughly review the job description and research the specific requirements for the position. Make sure you understand the duties and responsibilities of the role, as well as the qualifications and experience required.

- Visit the company’s website to learn about their products and services, as well as their commitment to safety and quality.

- Network with other aircraft mechanics and professionals in the industry to gain insights into the role and the company.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Quantify your accomplishments and provide specific examples of your work. If you have any certifications or training in aircraft rigging and controls, be sure to mention them.

- Use action verbs and specific examples to describe your experience in inspecting, maintaining, and repairing aircraft rigging and control systems.

- Highlight your knowledge of aircraft systems, rigging techniques, and applicable regulations.

3. Prepare for Technical Questions

Expect to be asked technical questions about aircraft rigging and controls during the interview. Be prepared to discuss your understanding of aircraft systems, rigging principles, and troubleshooting techniques. You may also be asked about specific tools and equipment used in the industry.

- Review common interview questions related to aircraft rigging and controls, such as “Describe the different types of aircraft rigging systems” or “How do you troubleshoot a malfunctioning flight control system?”

- Practice answering these questions clearly and concisely, providing specific examples from your experience.

4. Be Enthusiastic and Professional

Show your enthusiasm for the position and the industry. Be confident in your abilities and demonstrate your commitment to safety and quality. Dress professionally and arrive on time for the interview.

- Be prepared to talk about your passion for aircraft mechanics and your commitment to ensuring the safe operation of aircraft.

- Maintain eye contact, speak clearly, and listen attentively to the interviewer’s questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Rigging and Controls Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!