Feeling lost in a sea of interview questions? Landed that dream interview for Aircraft Riveter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aircraft Riveter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

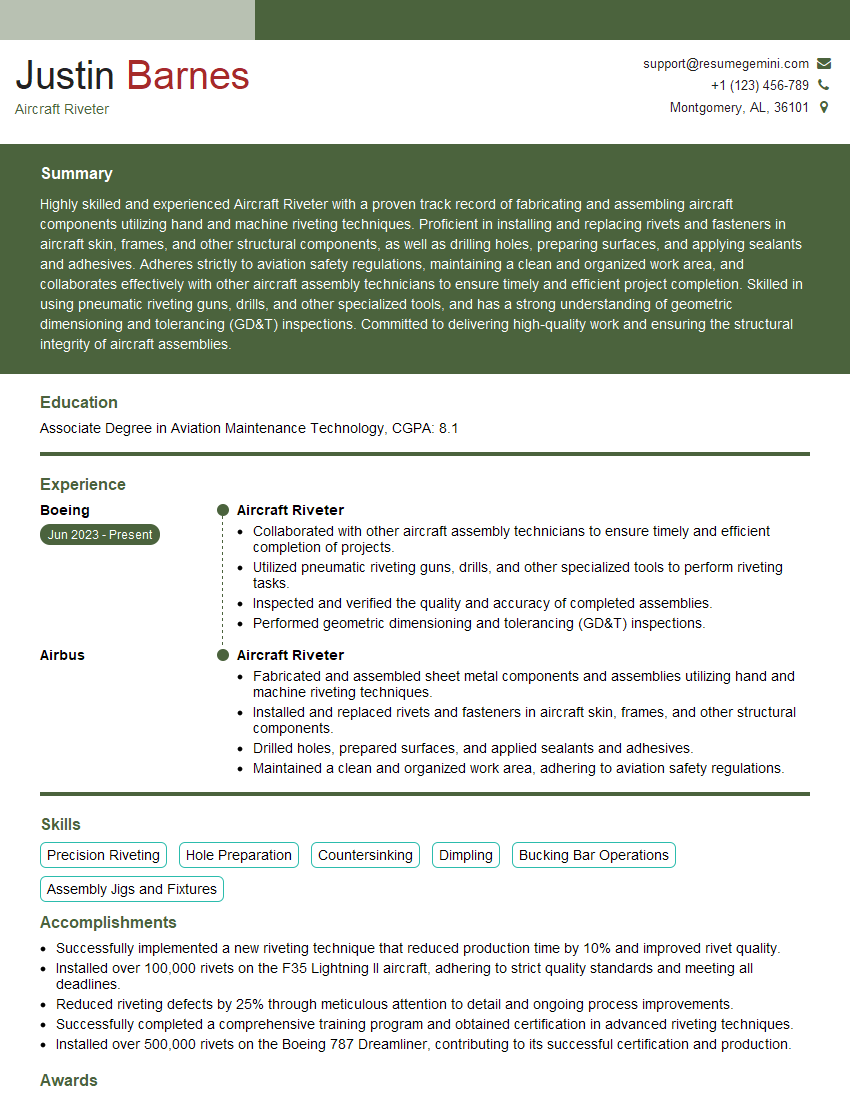

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Riveter

1. What are the different types of rivets used in aircraft construction?

There are three primary types of rivets used in aircraft construction:

- Solid Rivets: Made from a single piece of metal, solid rivets are the most common type used in aircraft construction. They are typically made of aluminum, stainless steel, or titanium.

- Blind Rivets: Blind rivets are used in situations where access to the opposite side of the material being riveted is limited. They consist of a rivet body and a mandrel that is pulled through the rivet body to set the rivet.

- Cherrymax Rivets: Cherrymax rivets are a type of blind rivet that provides high shear and tensile strength. They are often used in critical applications, such as attaching aircraft wings to the fuselage.

2. What are the different types of rivet guns used in aircraft construction?

Pneumatic rivet guns

- These are the most common type of rivet gun used in aircraft construction. They are powered by compressed air and use a piston to drive the rivet into place.

Electric rivet guns

- Electric rivet guns are powered by electricity and use a motor to drive the rivet into place.

- They are typically smaller and lighter than pneumatic rivet guns, making them ideal for working in tight spaces.

Manual rivet guns

- Manual rivet guns are powered by hand and use a lever to drive the rivet into place.

- They are typically used for small-scale riveting jobs or in situations where access to electricity or compressed air is limited.

3. What are the safety precautions that must be taken when working with rivets?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Ensure that the rivet gun is in good working condition and that all safety features are functional.

- Inspect the area where you will be riveting to ensure that there are no hazards, such as electrical wires or flammable materials.

- Do not point the rivet gun at yourself or others.

- Be aware of the location of your hands and fingers when operating the rivet gun.

4. What is the procedure for riveting a hole?

- Select the correct rivet size and type for the hole.

- Insert the rivet into the hole and align the rivet gun.

- Pull the trigger on the rivet gun to set the rivet.

- Inspect the rivet to ensure that it is properly set.

5. What is the difference between a flush rivet and a countersunk rivet?

Flush rivet

- A flush rivet is a rivet that is set below the surface of the material being riveted.

- This type of rivet is used when a smooth, aerodynamic surface is required.

Countersunk rivet

- A countersunk rivet is a rivet that is set into a countersunk hole in the material being riveted.

- This type of rivet is used when a flush surface is not required.

6. What are the different types of rivet heads?

- Round head

- Flat head

- Oval head

- Countersunk head

- Universal head

7. What is the purpose of a rivet squeezer?

- A rivet squeezer is a tool used to squeeze the rivet head against the material being riveted.

- This tool is used to ensure that the rivet is properly set and to prevent the rivet head from becoming damaged.

8. What is the difference between a rivet and a bolt?

- A rivet is a permanent fastener that is installed by driving or pressing the rivet into a hole.

- A bolt is a temporary fastener that is installed by threading the bolt into a nut.

9. What do you understand by the term “rivet spacing”?

- Rivet spacing is the distance between the centers of two adjacent rivets.

- The correct rivet spacing is important to ensure the strength and durability of the riveted joint.

10. What are the different types of rivet inspection methods?

- Visual inspection

- Magnetic particle inspection

- Radiographic inspection

- Ultrasonic inspection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Riveter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Riveter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Riveters are responsible for assembling aircraft components by driving rivets into holes. They work with a variety of materials, including aluminum, steel, and composites. Aircraft Riveters must be able to read and interpret blueprints and diagrams, and they must have a good understanding of aircraft construction.

1. Riveting Aircraft Components

Aircraft Riveters use riveting guns to drive rivets into holes in aircraft components. They must be able to accurately place rivets and ensure that they are properly set. Aircraft Riveters also use other tools, such as drills and hammers, to prepare the aircraft components for riveting.

- Drive rivets into holes in aircraft components using riveting guns.

- Accurately place rivets and ensure that they are properly set.

- Use other tools, such as drills and hammers, to prepare the aircraft components for riveting.

2. Inspecting Aircraft Components

Aircraft Riveters inspect aircraft components before and after riveting to ensure that they meet specifications. They look for defects, such as cracks, dents, and misalignments. Aircraft Riveters also use measuring tools to ensure that the components are the correct size.

- Inspect aircraft components before and after riveting to ensure that they meet specifications.

- Look for defects, such as cracks, dents, and misalignments.

- Use measuring tools to ensure that the components are the correct size.

3. Maintaining Riveting Equipment

Aircraft Riveters are responsible for maintaining their riveting equipment. They clean and lubricate the equipment regularly. Aircraft Riveters also troubleshoot and repair the equipment when necessary.

- Clean and lubricate riveting equipment regularly.

- Troubleshoot and repair riveting equipment when necessary.

4. Following Safety Procedures

Aircraft Riveters must follow all safety procedures when working on aircraft. They wear protective clothing and eyewear, and they use proper tools and equipment. Aircraft Riveters also follow lockout/tagout procedures when working on electrical equipment.

- Wear protective clothing and eyewear.

- Use proper tools and equipment.

- Follow lockout/tagout procedures when working on electrical equipment.

Interview Tips

To prepare for an interview for an Aircraft Riveter position, you should research the company and the position. You should also practice answering common interview questions. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position. This will help you to understand the company’s culture and the specific requirements of the position. You can find information about the company on its website and in online job postings. You can also find information about the position by talking to people who work in the industry.

- Visit the company’s website to learn about its history, culture, and products or services.

- Read online job postings to learn about the specific requirements of the position.

- Talk to people who work in the industry to get their insights on the company and the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked in an interview for an Aircraft Riveter position. These questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with riveting?”

- “How do you handle working in a team environment?”

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear clean, pressed clothing that is appropriate for a professional setting.

- Arrive for your interview at least 15 minutes early.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Be sure to show your interest in the position and the company during your interview. You should also be positive and upbeat, even if you are nervous.

- Make eye contact with the interviewer and smile.

- Speak clearly and confidently.

- Be enthusiastic about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Riveter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.