Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aircraft Structural Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aircraft Structural Repairer so you can tailor your answers to impress potential employers.

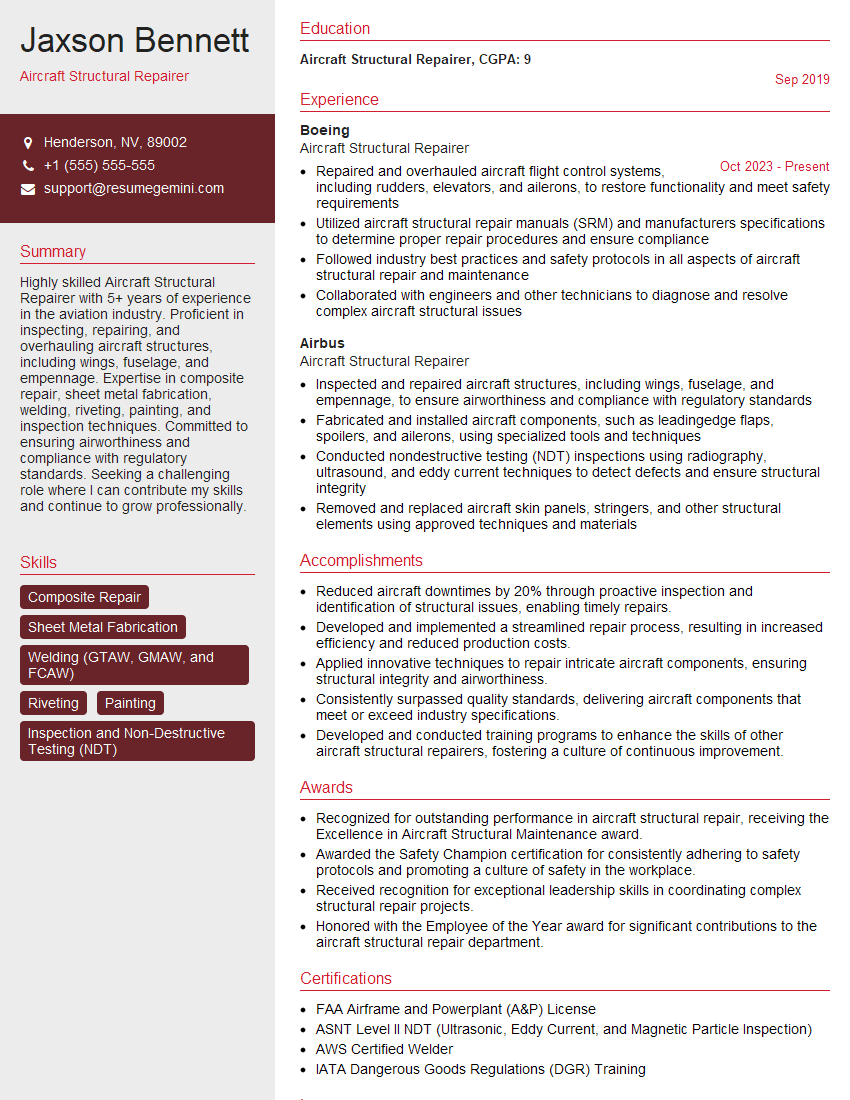

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Structural Repairer

1. Describe the steps involved in repairing a cracked aircraft skin?

Sample Answer:

- Assess the damage and determine the extent of the crack.

- Remove any damaged or loose material around the crack.

- Clean and prepare the surface of the skin.

- Apply a suitable repair material, such as a patch or sealant.

- Cure or bond the repair material according to the manufacturer’s instructions.

- Inspect the repair and ensure it meets all safety and performance standards.

2. What are the different types of aircraft structural materials and their properties?

Sample Answer:

Metals

- Aluminum: Lightweight, strong, and corrosion-resistant.

- Titanium: High strength, lightweight, and excellent corrosion resistance.

- Steel: Strong and durable, but heavier than aluminum or titanium.

Composites

- Carbon fiber reinforced polymers (CFRP): Extremely strong and lightweight.

- Glass fiber reinforced polymers (GFRP): Less strong than CFRP but more flexible.

- Kevlar: High strength-to-weight ratio and excellent impact resistance.

3. Explain the NDT methods used to inspect aircraft structures for damage?

Sample Answer:

- Visual Inspection: Examining the structure for visible cracks, corrosion, or other damage.

- Ultrasonic Testing: Using high-frequency sound waves to detect internal flaws.

- Radiographic Testing: Using X-rays or gamma rays to penetrate the structure and reveal internal defects.

- Eddy Current Testing: Using electromagnetic induction to detect surface and subsurface cracks.

- Magnetic Particle Inspection: Using magnetic particles to detect surface cracks.

4. What are the key considerations in choosing the appropriate repair method for different types of aircraft damage?

Sample Answer:

- Location of the damage: Structural integrity, accessibility, and impact on flight performance.

- Type of damage: Cracks, corrosion, dents, or more complex structural failures.

- Materials involved: Compatibility with existing materials, strength and durability requirements.

- Regulatory requirements: Adherence to industry standards and safety guidelines.

- Cost and time constraints: Availability of resources and impact on aircraft availability.

5. Describe the quality control procedures involved in aircraft structural repair?

Sample Answer:

- Thorough inspections: Before, during, and after the repair to ensure compliance.

- Documentation: Maintaining detailed records of all repair steps, materials used, and quality checks.

- Compliance audits: Internal or external reviews to verify adherence to established standards.

- Training and certification: Ensuring technicians are highly skilled and qualified.

- Feedback and continuous improvement: Analyzing the quality of repairs and identifying areas for enhancement.

6. What are the safety precautions to observe when working on aircraft structural repairs?

Sample Answer:

- Proper grounding techniques: Preventing electrostatic discharges and electrical hazards.

- Use of fall protection equipment: Minimizing risks of slips and falls.

- Secure work area: Preventing accidents and protecting surrounding structures.

- Adequate ventilation: Avoiding exposure to harmful fumes or dust.

- Proper handling of chemicals: Ensuring safe use and disposal of hazardous materials.

7. Explain the importance of maintaining accurate technical records for aircraft structural repairs?

Sample Answer:

- Ensuring accountability: Tracking responsibilities and approvals for repairs.

- Facilitating inspections and audits: Providing detailed information for quality assurance.

- Supporting maintenance and repair history: Assisting in future troubleshooting and repair decisions.

- Improving safety: Capturing lessons learned and identifying potential risks or defects.

- Compliance with regulations: Meeting industry standards and regulatory requirements.

8. What is your experience with using specialized tooling and equipment for aircraft structural repairs?

Sample Answer:

- Hand tools: Angle grinders, drills, rivet guns, hydraulic jacks.

- Power tools: Impact guns, air hammers, sanders, orbital saws.

- Specialized equipment: Hydro-mechanical presses, laser alignment systems, composite repair tools.

9. How do you stay up-to-date with advancements and changes in aircraft structural repair techniques?

Sample Answer:

- Attending industry workshops and conferences.

- Reading technical journals and industry publications.

- Consulting with manufacturers and suppliers.

- Participating in online forums and discussion groups.

10. Describe a challenging aircraft structural repair you have encountered and how you overcame it?

Sample Answer:

- Describe the damage: Extent, location, and type of structural damage.

- Challenges faced: Technical complexity, access limitations, or material compatibility.

- Solutions implemented: Innovative repair methods, specialized tooling, or collaboration with experts.

- Results achieved: Successful repair, restoration of structural integrity, and compliance with safety standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Structural Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Structural Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Structural Repairers are responsible for the repair and maintenance of aircraft structures, including the fuselage, wings, and control surfaces. They use a variety of tools and techniques to repair damage caused by accidents, corrosion, or wear and tear.

1. Inspect aircraft structures for damage

Inspect aircraft structures for damage, such as cracks, dents, and corrosion. Use a variety of tools and techniques to identify damage, including visual inspection, ultrasonic testing, and radiography.

2. Repair damaged aircraft structures

Repair damaged aircraft structures by welding, riveting, bonding, or replacing damaged parts. Use a variety of tools and techniques to repair damage, including hand tools, power tools, and specialized equipment.

3. Test repaired aircraft structures

Test repaired aircraft structures to ensure that they meet safety standards. Use a variety of tools and techniques to test repairs, including visual inspection, non-destructive testing, and flight testing.

4. Maintain aircraft structures

Maintain aircraft structures by cleaning, lubricating, and inspecting them regularly. Use a variety of tools and techniques to maintain aircraft structures, including hand tools, power tools, and specialized equipment.

Interview Tips

To ace an interview for an Aircraft Structural Repairer position, it is important to be prepared. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the position. You can find information about the company on their website, in industry publications, and through networking.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Aircraft Structural Repairer. Be prepared to discuss your experience repairing and maintaining aircraft structures, as well as your skills in welding, riveting, bonding, and other repair techniques.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a good time to ask about the company’s culture and the opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Aircraft Structural Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.